ZPW125 Single Rotary Compression Machine

A Single Rotary Compression Machine, often simply called a single station or single punch tablet press, is a fundamental and widely used type of equipment in industries such as pharmaceuticals, nutraceuticals, food, and chemicals for the production of tablets.

Need a Custom Quote?

Or More information About this product? Contact our sales stuff today!

Key Features

Technical Data

Machine Details

FAQ

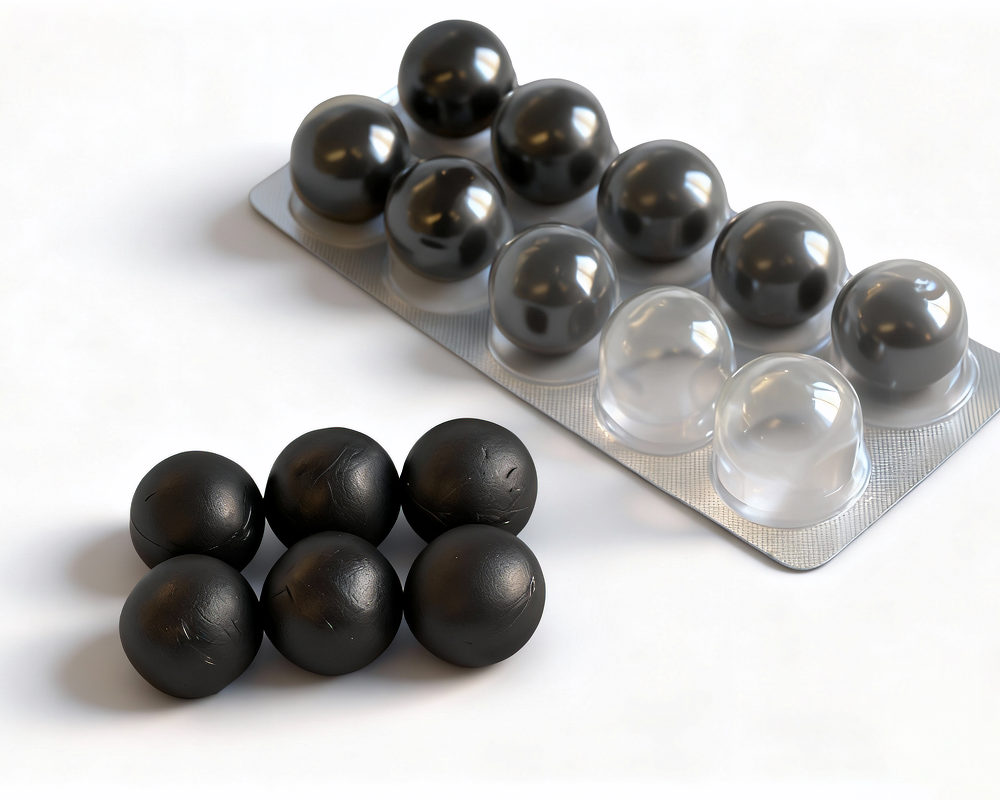

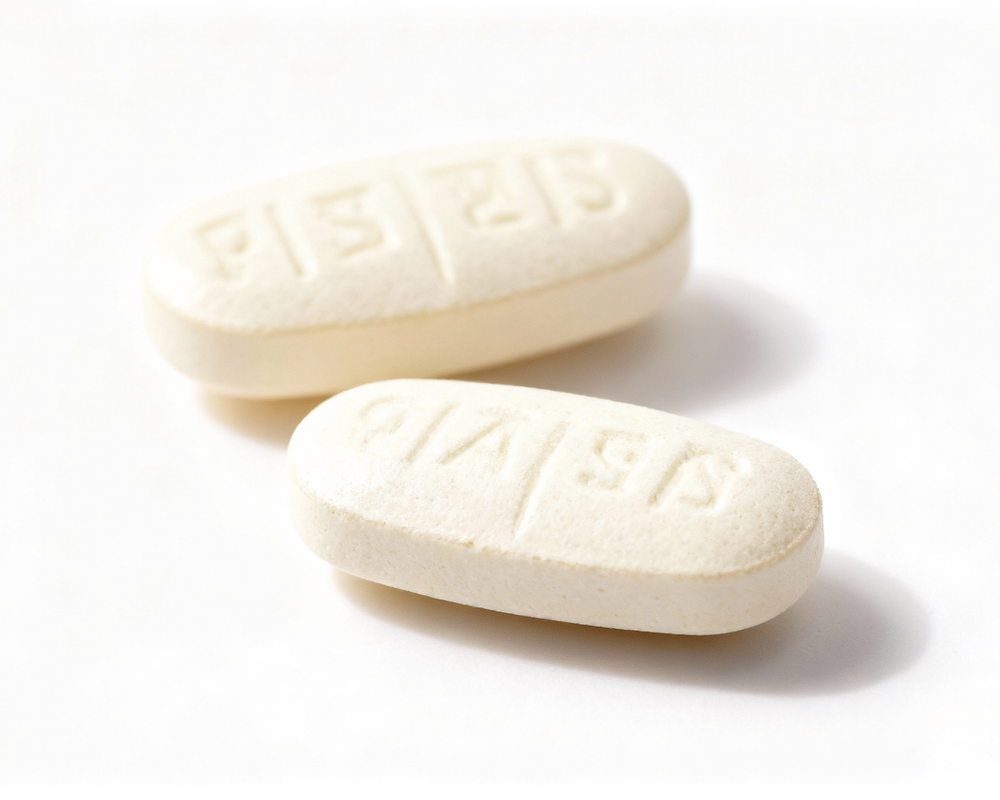

Application

- This machine is fully functional, capable of producing not only round tablets but also irregularly shaped tablets, ring-shaped tablets, and double-sided engraved tablets. It can produce single-layer tablets as well as double-layer and triple-layer tablets, meeting diverse user needs.

- The machine complies with GMP requirements. The compression chamber is isolated from the transmission components to prevent material contamination. All parts in contact with the product are made of 316L stainless steel or feature a coated surface, ensuring non-toxicity, wear resistance, and corrosion resistance.

- The ZPW series multi‑purpose tablet press features an integrated mechanical and electrical design, making it easy to operate, maintain, and service.

- Equipped with a PLC programmable controller, it monitors key functions and detects faults during the tableting process.

- A touch screen allows operators to intuitively set and display essential parameters, such as average compression pressure, upper and lower limits, pass rate of finished tablets, and various fault alerts for easy selection and monitoring.

- With a variable‑frequency speed regulation device, the machine offers smooth, reliable, and wide‑range stepless speed control. It uses a variable‑frequency motor to ensure constant power and torque within a certain frequency range, meeting torque requirements across the specified operating speeds.

- This machine has been awarded the National Key New Product Certificate.

| Model: | ZPW25 | ZPW31 | ZPW37 | |

| Number of Stations: | 25 | 31 | 37 | |

| Tooling Standard: | D | B | BB | |

| Max Main Pressure(KN): | 80 | |||

| Round tablet: | 25 | 18 | 13 | |

| Max Tablet Diameter(mm): | Irregular tablet: | 25 | 19 | 16 |

| Max Filling Depth(mm): | 18 | |||

| Max Tablet Thickness(mm): | 7 | |||

| Max Turret Speed(r/min): | 20 | 35 | 40 | |

| Max Production Capacity(pcs/h): | 30000 | 65100 | 88800 | |

| Motor Power(kw): | 4 | |||

| Overall Size(mm): | 1050x900x1880 | |||

| Machine Weight(kg): | 2000 | |||

A Single Rotary Compression Machine is a mechanical press used primarily in the pharmaceutical, nutraceutical, and chemical industries to produce tablets. It features a single turret (rotating head) with dies that are filled with powder. Punches (upper and lower) then compress the powder under high pressure within the dies to form uniform, solid tablets in a continuous, rotary motion.

The key difference is scale and output. A Single Rotary machine has one set of punches (upper and lower) on a single turret, typically with fewer stations (e.g., 15-45). It is ideal for R&D, pilot-scale production, and low to medium output. A Double Rotary press has two separate turrets and compression stations within one machine, effectively doubling the output for high-volume commercial production.

Cost-Effective: Lower initial investment and operating costs.

Flexibility: Perfect for small batches, product development, and frequent changeovers.

Ease of Operation & Maintenance: Simpler design makes it easier to learn, clean, and maintain.

Space-Efficient: Requires less floor space in the production lab or facility.

Precision: Modern single rotary machines offer excellent weight control and hardness uniformity for their capacity.

They are versatile and also used in:

Nutraceuticals: (Vitamins, supplements)

Cosmetics: (Pressed powders, bath tablets)

Food Industry: (Bouillon cubes, candy tablets)

Chemicals: (Catalysts, cleaning product tablets)

Electronics: (Ceramic components)

Operators can precisely control:

Tablet Weight: Via adjustable powder fill depth.

Tablet Hardness & Thickness: Via adjustable main compression force.

Production Speed: Via variable turret rotation speed (RPM).

Dwell Time: Often fixed by design, but critical for certain formulations.

The machine requires a set of punches and dies, known as "tooling." The most common standard is B-tooling (as per TSM/EBU standards). It's crucial to specify the correct tooling type (B, D, BB, etc.), punch head configuration, and tablet shape/size when ordering. The machine manufacturer can provide compatible tooling.

Single-layer tablets of various shapes (round, capsule, oval, custom) are standard. For bi-layer tablets, a specialized single rotary press with two feeding systems is required. For coated tablets, the machine produces the core tablet which is then coated in a separate process.

Yes, but you must select a machine designed with GMP principles: easy-to-clean surfaces (stainless steel, polished), minimal particle traps, documented calibration, and validation support (IQ/OQ/PQ). The machine itself is a tool; the overall process and documentation ensure regulatory compliance.