Making medicines safely needs very special equipment. Many companies build these important machines worldwide. China has top makers who know a lot about this, playing a big part in supplying these tools globally.

Pharmaceutical machinery is the special equipment used to make drugs. These machines do many jobs, like mixing items, making pills, or filling small bottles. They also package the finished medicines, always keeping things very clean and exact, which is key for safety.

| Company Name | Year Founded |

| Truking Technology | 2000 |

| Tofflon Science and Technology Group | 1993 |

| Shinva Medical Instruments | 1943 |

| Zhejiang Canaan Technology | 2000 |

| Finetech | 1992 |

| Chutian Technology | 1998 |

| IMA Group | 1961 |

| Liaoyang Zhonglian Pharmaceutical Machinery | 2001 |

| Jornen Machinery | 1989 |

| Huada Pharma | 1992 |

Trucking Technology

Year Founded: 2000

Main Products:

- Liquid injectable production lines.

- Oral solution processing systems.

- Smart secondary packaging equipment.

- Purified water and clean steam plants.

- Integrated “turnkey” pharmaceutical factories.

Truking Technology is a company. It is in Changsha, Hunan Province. They design machines. They also build machines. They set up these full machine systems for people who buy them.

These machines do many kinds of work. They make medicines. They fill containers with medicines. They check the medicines. They also package medicines. These are medicines that get injected into a person’s body.

You might see these medicines in IV bags. Sometimes they are in small bottles. These bottles are called vials or ampoules. These medicines must stay sterile. Sterile means they have no germs at all. This is important. It keeps patients safe when they take the medicine.

The company began as Changsha Packaging Machinery Co. It started in a building. That building used to be a cowshed! That’s a fun detail.

Now, it’s a large company. Its shares are even sold on the Shanghai stock exchange. They also make equipment for treating water. They make robots too. Plus, they have an engineering part. This part can build whole new drug factories from the start.

Yue Tang founded the company. He is still the chairman. He decided to mix their main machines with digital computer systems. These systems are called SCADA and MES. This helps their customers get their production lines approved.

These approvals follow new European and US rules. Examples are EU-GMP Annex 1. Another is FDA 21 CFR Part 11. These rules are very important. They make sure all drugs are safe.

In 2017, Truking bought a German company. This company was Romaco Group. After this, Truking started to offer European machines for making tablets. They also offer machines for packing them. They provide these along with their own machines for injected medicines. So, big international buyers can get all sorts of drug-making equipment from one place.

The company put a lot of money into its “Watertown” campus. This campus is in Ningxiang. This place has special centers for robots. These robots work with pre-filled syringes. It also has centers for research. This research is on special clean areas called isolator barriers.

They also have labs to test equipment. This testing happens before it goes to a buyer’s factory. It makes sure the equipment meets high-quality standards. These standards are known as cGMP.

Truking’s technical service team helps people all over the world. They assist with setting up equipment. They also help with checking it. They train staff right at the buyer’s location. This team supports over 2,000 production lines. These lines are running in more than 40 countries.

Tofflon Science and Technology Group

Year Founded: 1993

Main Products:

- Freeze dryers and automatic loading systems.

- Isolator barrier filling lines for vials, PFS, and cartridges.

- Single-use bioprocess skids and chromatography columns.

- OSD granulation, coating and containment suites.

- Cleanroom HVAC and turnkey clean utilities.

Tofflon Science and Technology Group has its main office in Shanghai. The company supplies many different kinds of equipment. This goes from tools for lab development to large machines for making things. They can even deliver entire finished projects.

The founder is Zheng Xiaodong. He started the company small. It began with a little workshop. This workshop made vacuum freeze-dryers. Now, Tofflon owns eight factories in China. They also have research and development centers. These are in Germany and the USA.

Their Preparation Equipment Division builds lines for filling vials. These lines are kept separate by barriers. This keeps things clean. They can handle 600 vials every minute. They use advanced robots to do this.

The Bio-process Division provides fermenters. These are often used once. Then they are thrown away. They also supply other equipment. This equipment is for making modern medicines. These medicines include vaccines. They also include treatments that use cells and genes.

Tofflon’s engineers combine these systems. They use their own heating, ventilation, and air conditioning (HVAC). They also add cleaning systems. They make sure that their data platforms meet all the rules. These rules are for accuracy and being reliable.

In 2017, the group started something. It was called the (M+E+C)AI initiative. This project uses machine learning. Machine learning is a type of smart computer program. It helps make freeze-drying processes better. It also improves how they look at sterile production lines to check them.

This has helped cut down the time needed for freeze-drying. The time cut can be as much as 20 percent. Tofflon works with large drug companies. These companies are in Europe and North America. Tofflon has 13 offices in other countries to provide service. These offices also store spare parts.

Some of their recent projects include complete setups for cell and gene therapy. These use advanced isolators. Isolators are very clean, closed-off spaces. These setups meet high European standards. These standards are for keeping conditions inside vials free of germs. This can be done without needing old-style clean-room clothes.

Shinva Medical Instruments

Year Founded: 1943

Main Products:

- Large capacity steam and low temperature sterilizers.

- Radiation therapy systems and digital imaging suites.

- Washer disinfectors and CSSD logistics robots.

- Compounding isolators and clean room equipment.

- Pharmaceutical water treatment and waste sterilization units.

Shinva Medical Instruments is in Zibo, Shandong Province. It’s China’s oldest maker of medical equipment. It also makes drug-making equipment. And it has been running without stopping for all that time.

The company was started during a war. Its job was to give supplies to hospitals. These hospitals were in the field. Now, it has nine industrial parks. These parks make machines for healthcare. They also make them for drug companies.

For drug companies, their sterilization part makes big steam sterilizers. These are also called autoclaves. They also make low-temperature sterilizers. These use hydrogen peroxide. This chemical cleans equipment for making sterile drugs. Sterile means completely free of germs.

The company’s engineering institute works with Chinese groups. These groups include CMDA and NMPA. Together, they help set national standards. These standards say how well sterilizers should work. Because they work together, Chinese inspectors usually accept Shinva’s testing methods.

The part of the company that deals with radiation equipment uses its knowledge. It knows about special machines called linear accelerators. They use these to provide powerful electron-beam sterilizers. Factories that make vaccines and syringes use these sterilizers. They make sure products are completely clean at the very end of production.

A strong tradition of research and development started with the founder. This has led to new products. One example is washer-disinfector racks. These racks use artificial intelligence.

These smart racks can change their spray pressure. They do this based on what they are washing. This saves water. It also makes the cleaning cycle shorter.

Shinva also designs complete central sterile supply departments. These are for hospitals. And they offer training centers for good manufacturing practices. There, workers can practice important steps. The company sells its products in many places. These range from Southeast Asia to South America. Many products have CE marks. These marks show they meet certain European safety and performance rules.

Zhejiang Canaan Technology

Year Founded: 2000

Main Products:

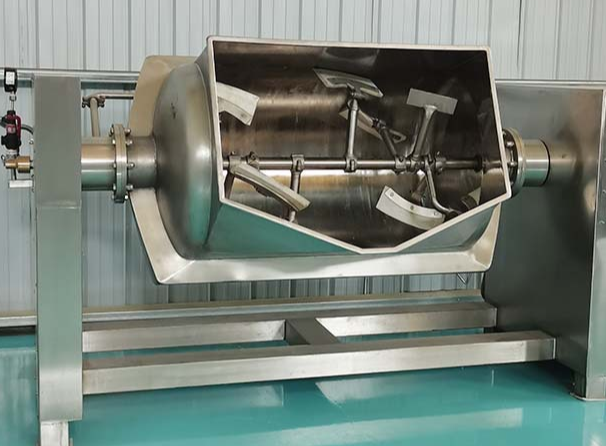

- High shear mixers and fluid bed granulators.

- Roller compactors and bin blenders.

- Tablet presses and capsule fillers.

- OEB isolators for potent OSD manufacturing.

- Integrated warehouse and AGV material handling solutions.

Zhejiang Canaan Technology works from the Yongjia Industrial Park. This park is in Wenzhou. It was the first company in China that makes equipment for solid medicines to be listed on a stock market. Solid medicines are things like tablets.

The founder, Fang Hengzhi, started the company. It now provides complete systems for making these oral solid dosage (OSD) drugs. These systems handle everything. This includes measuring out raw materials in special clean booths. It also includes mixing, shaping, and coating tablets. They also cover packaging. And they manage automatic warehouse systems.

The company uses a digital system. It is called “Canaan iPharma.” This system connects sensors that watch processes. It manages recipes for making drugs. It also links to the main manufacturing computer systems.

This setup allows for good record-keeping. This record-keeping follows rules like CFR Part 11. It also gives live information. This information shows how well the equipment is running.

The current chairman is Zheng Fang. He supports a strategy called “Three Health.” This strategy focuses on the health of the equipment. It also focuses on the health of the products. And it looks at the health of the business itself. This has led to building three production sites. They also have extra testing centers in other cities.

Canaan’s isolator technology is made for safely handling very strong drugs. This meets what’s called OEB 4/5 containment levels. This means the equipment gives a very high level of protection to workers.

These systems include special valves for moving materials. They also have quick ways to clean the equipment. This cleaning uses vaporized hydrogen peroxide. This allows for making medicines like cancer tablets all the time. For these drugs, it’s important to keep worker exposure very, very low.

The company also has an academy. This academy trains technicians from companies that buy their equipment. They learn how to manage granulation processes when making larger amounts. They also learn how to fix problems with tablet presses. This helps support service deals in about 90 countries.

Finetech

Year Founded: 1992

Main Products:

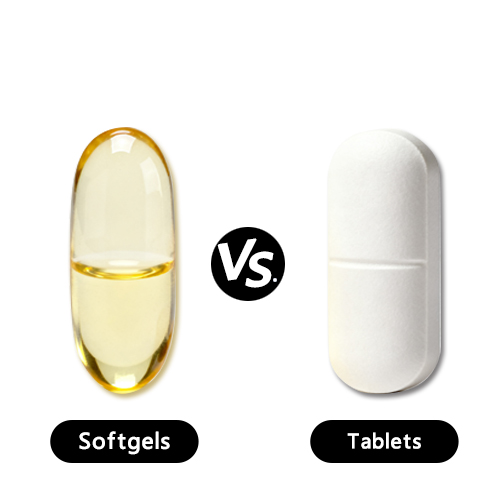

- Automatic capsule filling machines (NJP series).

- Liquid in hard capsule filling and sealing systems.

- Multi-channel electronic pill counters.

- Blister and bottling downstream equipment.

- Ancillary inspection and printing units.

Finetech has its main office in Ruian, Zhejiang Province. This area is known for new ideas in machines. These machines make capsules. Tony Tao is the Chief Executive Officer. He helped start the business in the early 1990s.

Mr. Tao has guided Finetech. The company focuses on technologies that measure out exact doses. These are useful for making nutritional supplements. They are also good for making regulated medicines. The factory first made capsule fillers. These had to be operated by hand.

Now, it builds advanced models. These use servo motors. They can fill 24,000 capsules an hour! That’s very fast. These machines have systems that adjust the weight by themselves. They also use vacuum technology to fill capsules very accurately. This works well even with powders that are hard to use.

Their equipment for making liquid-filled capsules includes precise pumps. It also has heated containers for the liquid. And it has systems that seal the capsules after they are filled. This allows companies to sell products with oil-based parts. It also lets them make products that are not soft-gel capsules but work like them.

Finetech’s engineers design special clean enclosures. They also make HEPA laminar-flow modules. These are special air filters. They also make cleaning pipes themselves. This approach helps reduce problems for buyers. It’s good for those who want to get quick approval from groups like the FDA.

The company also provides single units. These units can fill bottles. They can also cap and seal them. This means new businesses can get a whole setup for making oral solid medicines. And they can get it from just one supplier.

Finetech sells its products around the world. It has CE and UKCA certifications. These show they meet certain standards. They have technical people in several regions. These people can deliver parts quickly if needed.

Finetech keeps investing in high-precision machining. This helps them make critical parts very accurately. This is a big reason why Finetech has a good name. They are known for reliable machines. These machines are used in factories that produce large amounts of generic drugs.

Chutian Technology

Year Founded: 1998

Main Products:

- Ampoule, vial, and oral liquid compact lines.

- Intelligent visual inspection systems for parenterals.

- Sterile water preparation and distribution equipment.

- Blow-fill-seal machines for BFS injectable plastics.

- High-speed syringe assembly and packaging lines.

Chutian Technology is based in Changsha, Hunan Province. It focuses on solutions for quickly producing liquid medicines. The founder is Mr. Li Chang-cheng. He made it a priority to work with Chinese universities. They worked together on research and development.

These partnerships led to the creation of their own special capping devices. They also developed no-touch filling valves. These can measure volumes very accurately. They work well even when filling 600 containers a minute.

Chutian’s main compact line for vials does many things. It handles washing. It also does heat sterilization. This is called depyrogenation. It also does filling, putting in stoppers, and capping. All this happens within one very clean, closed-off space.

This whole system is designed to fit into a small area. It’s about 7 meters long. This makes it good for updating older factories.

The company’s automation department creates computer programs. These programs use machine vision. This is like a smart camera system. They can spot tiny particles. They can also find small flaws on the products. This follows guidelines like the US USP <1790> for quality control.

Chutian’s blow-fill-seal (BFS) system uses special molds. It also has built-in cleaning units. This setup allows users to quickly switch. They can switch between making different products. For example, they can change from eye drops to small injectable medicines. This happens with very little downtime.

Chutian has worked with another company, Advantech. Together, they have included SCADA systems. They also use digital twin simulations. Digital twins are virtual copies of the real machines.

These digital tools allow customers to practice changes. They can also rehearse sterile procedures. They do this in a virtual world. They do this before they perform them on the actual production line.

Chutian sells its machinery to over 50 countries. They also offer support. This support comes through a remote diagnostic center. This center can solve most alarms without a technician needing to visit the site. This helps keep production high for companies. These companies make vaccines and infusions.

IMA Group

Year Founded: 1961

Main Products:

- Tablet presses and capsule filling machines.

- Aseptic processing and freeze-drying lines.

- Blister and tray packaging machines.

- Tube fillers and cartoners.

- End-of-line packaging and automation systems.

IMA Group is based in Bologna, Italy. It is a world leader in machines for processing and packaging. These are for drugs, cosmetics, and food. It aims to provide a wide range of solutions for many industries. The company is well known for its large size and broad scope of equipment.

It was founded by the Vacchi family. It started by making machines to package tea bags. Now, it has grown into a large group with many divisions. Some of these are IMA Active for solid dose drugs, IMA Life for sterile processing, and IMA Safe for packaging. Each one focuses on a special area of machinery.

The IMA Active division offers full systems for making oral solid dose drugs. This includes granulators, tablet presses, and capsule fillers. Their machines are known for being very precise. They are also famous for handling very strong drugs safely, which protects workers.

IMA Life is the division for sterile production. It is a leader in aseptic filling, which means filling without germs. They make freeze dryers and automatic loading systems for injectable drugs. Their isolator technology helps keep products pure. It also protects the people who operate the machines.

IMA puts a lot of money into research and development. They focus on digital tools. Their “IMA Digital” program helps create smart machines. These machines can predict when they need maintenance. This helps prevent downtime. They also help drug makers meet data integrity rules.

The company provides full support to its global customers. This includes setting up the machines and training staff. They have many production sites across Europe and the world. They also have a large network of sales and service offices. This helps them support machines in countries all over the world.

Liaoyang Zhonglian Pharmaceutical Machinery

Year Founded: 2001

Main Products:

- Tubular and disc stack centrifuges.

- Continuous decanter centrifuge lines.

- Alcohol recovery distillation skids.

- Herbal extraction and filtration systems.

- Small-scale lab separators for pilot trials.

Liaoyang Zhonglian Pharmaceutical Machinery is in Liaoyang, Liaoning Province. This area has a history of making centrifuges. Centrifuges are machines. They spin very fast to separate different materials.

Zhonglian focuses on solutions for separating solids from liquids. This is very important. It helps clean up active pharmaceutical ingredients (APIs). It’s also key for making biotech broths clear. Broths are liquids used in making some medicines.

The founder is Zhang Guoqiang. He used the local knowledge in heavy machinery. He used it to create high-g-force disc-stack centrifuges. These machines can clear liquids. They do this by removing very small particles. They are often used in plants. These plants make antibiotics and plasma proteins.

The company provides special decanters. These are explosion-proof. They also have sealed designs. These features allow factories to get back and reuse solvents. This is useful when taking out things like nutraceuticals. Nutraceuticals are health supplements. It is also used for cannabinoids. These are compounds from cannabis plants. This process follows safety rules like ATEX directives. These rules are for dangerous areas.

Its engineering team can choose special metals for the centrifuge bowls. They might use duplex, super duplex, or Hastelloy. This is to handle materials that can cause damage by corrosion. For example, fermentation liquids that have acids or chlorides in them.

Zhonglian’s control systems use computers from Siemens. They also include systems that watch for vibrations. If there’s a problem, these systems can automatically start cleaning and balancing routines. This helps the machine’s bearings last longer. It also means the machine is out of service less often.

They also offer services like looking at vibration data from far away. And they have programs for swapping out spare bowls. This helps factories that make APIs all the time. It helps them guess when they will need to do maintenance.

Jornen Machinery

Year Founded: 1989

Main Products:

- Blister packaging machines and feeders.

- Cartoners and end-of-line case packers.

- Capsule fillers and strip packing lines.

- Film coating and tablet press machines.

- Thermoforming packaging systems.

Jornen Machinery is based in Shanghai. It was started by Mr. Yang Yijun. He was a leader in developing China’s first platen-style blister machine. This is a type of packaging machine.

Since it started, the company has grown. It now offers a full range of equipment. This equipment is for packaging medicines taken by mouth. It supplies modular blister and cartoning lines. These lines work together very precisely. They make sure things line up with an accuracy of 0.3 millimeters or better.

Jornen’s main DPP series of machines uses servo motors. These help with smooth movement. They also use contact-heating stations. These are for different packaging formats like PVC-PVDC and ALU-ALU. These are types of plastic and foil. These machines can produce over 500 blister packs every minute.

They have a special “QuickLock” die-change system. Dies are shaping parts of the machine. This system allows for quick changeovers. These take about 15 minutes. This is very helpful for businesses. These businesses package many different kinds of products.

The company includes camera inspection in its lines. It also has tests for leaks. And it does weight checks. They export complete systems. These systems meet international standards like ISO 14644 and GAMP 5.

Its research and development center works with Shanghai Jiaotong University. They study the science of how blisters are formed. This teamwork has led to lower temperatures needed for forming the blisters. This reduces problems with PVC packaging. One problem is puckering. It also saves energy.

Jornen’s global network reaches more than 100 countries. They have spare-parts hubs. These are in Frankfurt, Germany, and São Paulo, Brazil. These hubs make sure they can deliver critical wear items in 72 hours. Examples are cutting knives and forming plugs.

Huada Pharma

Year Founded: 1992

Main Products:

- Hard gel and liquid in capsule filling machines.

- Automatic tablet counters and bottling lines.

- Softgelatin encapsulation systems.

- Blister packaging machines.

- Capsule inspection and polishing devices.

Huada Pharma has its main office in Wenzhou, Zhejiang. It grew from the first Ruian Huada Pharmaceutical Machinery Factory. Now, it focuses on technology for making capsules.

Since it began, the company has focused on creating unique dosing systems. These are systems that it can get patents for. Its newest NJP 7500 series machines use a special three-camming station. This design keeps the dosing disc’s vibration separate. The dosing disc is the part that measures the powder. This separation helps keep the weight consistent. This is very true with powders that easily soak up moisture from the air.

Their systems for making liquid-filled capsules use servo-driven pistons. These allow for very accurate measuring. The accuracy is within ±1 percent. They also have built-in cleaning and steaming cycles. These features help speed up media-fill validation. Media-fill validation is a test. It confirms the equipment is sterile and ready.

The founder, Hu Xiaoming, encouraged a strong research and development culture. This has resulted in over 40 national patents. One of these patents is for tamping pins. These pins can adjust themselves. They do this if the density of the granules changes during long production runs.

Huada’s packaging department sets up rotary blister machines. These machines have special brushless knives. These knives make perforations. Perforations are the tear-off lines on packaging. They also have full-height vision rejection towers. These use cameras to spot and remove faulty products. This helps companies that package over-the-counter products. It helps them meet strict line-clearance rules. This is especially true for US retailers.

The company holds ISO 9001 and CE certificates. It also provides FDA QSR documents. QSR means Quality System Regulation. These are for buyers in North America. This is helped by an English-language online learning portal. This portal covers how to maintain and fix capsule fillers.

An on-site machining center makes turrets. Turrets are key parts of the capsule fillers. They are made from 316L stainless steel. They are made in a single-piece casting. This means there are no weld seams. This design choice makes them stronger. It also makes the machines easier to clean. This follows cGMP, which means current Good Manufacturing Practices.

Conclusion

Pharmaceutical machinery is truly very important for making our medicines. Companies that build this equipment have a big responsibility. Their efforts help make sure we get treatments that are safe and effective.