Capsule production may appear simple from the outside, but behind every perfectly formed capsule lies a precise piece of tooling, known as the capsule mold. In pharmaceutical manufacturing, capsule molds determine capsule shape, size, accuracy, and consistency.

If the mold is incorrect, even the best capsule filling machine cannot produce uniform results. That means rejected batches, wasted material, and delayed production.

However, before you run over to choose a mold, you need to know what types exist, how they work, and what specifications matter most.

Let’s break it down in the simplest and most practical way.

Key Takeaways

- What It Is: A capsule mold is a precision tool that forms empty capsule shells (the body and cap) before filling. It controls size, thickness, and locking strength to guarantee capsules fit and seal correctly.

- Types of Capsule Molds: The most common types of capsule molds available in the pharmaceutical industry include gelatin, HPMC/vegetarian, soft capsules, microcapsules, and industrial mass production capsules.

- How It Works: Capsule molds shape gelatin or HPMC into capsule shells through a dipping and drying process. Pins are dipped into the liquid material, rotated, and dried, then the hardened shells are stripped and joined into the capsule body and cap.

What Are Capsule Molds?

Capsule mold is a precision tooling set that forms the empty capsule shells, the body, and the cap, which later get filled with active ingredients. Think of it as the “frame” of the capsule: it defines the capsule size, wall thickness, shape, and fit of the two capsule halves.

Without a well-engineered mold, you risk capsules that won’t join properly, drop product, or fail on high-speed lines.

These capsule molds are often used in a dipping process where pins or molds are lowered into a gelatin or polymer solution. The shell then forms on the mold surface, dries, and is afterward stripped off to become the capsule halves ready for filling.

Types of Capsule Molds Used In Pharma

Capsule molds are categorized based on capsule material, shape/style, and mold construction material. These factors influence capsule consistency, drying speed, and production accuracy. Here are the common types of capsule molds you should know about:

1. Silicone Capsule Molds

Silicone gelatin capsule molds are engineered specifically to produce hard gelatin capsule shells. Gelatin becomes workable when heated, so the dipping tanks are kept warm and controlled. The mold pins are dipped into the gelatin mixture, and a thin film sticks to the pins to form the shell.

This mold matters because:

- Gelatin dries faster and shrinks slightly during the drying process.

- Molds must have a precise pin diameter to ensure consistent shrinkage.

- If molds are not properly calibrated, capsule walls may come out uneven, leading to filling issues.

Interesting fact: Gelatin capsule molds dominate the industry because gelatin capsules account for over 60% of global capsule production.

2. HPMC / Vegetarian Capsule Molds

These molds are designed for capsules made from HPMC or pullulan, which are plant-derived materials. Unlike gelatin, HPMC does not shrink as much during drying. That means molds for HPMC capsule require:

- Contrasting pin surface smoothness.

- Different drying temperature control.

- Longer drying time to avoid brittleness.

HPMC capsule molds are ideal for moisture-sensitive formulations and are used in halal, kosher, vegan, and clean-label supplement markets. Because HPMC solution behaves differently during dipping, molds are manufactured with finer pin tolerances.

3. Soft Capsule Molds

Soft capsule molds are completely different from molds used for hard capsules. Instead of forming a hollow shell first, soft capsule molds shape and seal the softgel capsule in a single step.

These molds are part of a rotary die system that operates as follows.

- Two cylinder-shaped molds (called die rolls) rotate together.

- A heated gelatin sheet passes between them.

- Liquid fill material is injected at the exact moment the die rolls press together.

- The capsule is formed, shaped, filled, and sealed, all at once.

Compared to hard capsule molds, soft capsule mold systems require higher temperature control and more complex tooling calibration.

4. Micro-Encapsulation Capsule Molds

These molds are used for mini capsules, microcapsules, or beadlets that are much smaller than standard capsule shells. These miniature capsules range from 0.5 mm to 4 mm and are used for controlled release, taste masking, or encapsulating liquids.

Micro-encapsulation molds require ultra-precise pins and controlled environments. It’s because microscale capsules are more sensitive to variations in drying and to pin imperfections.

5. Industrial Capsule Molds

Lastly, we have the industrial capsule molds. These are utilized in fully automated capsule shell manufacturing lines. They are designed for 24/7 operation in industrial environments and typically include:

- Multi-pin mold plates (hundreds of pins per cycle).

- Automated dipping, drying, trimming, and joining stages.

One of the biggest benefits of such molds is that they can produce millions of capsules per day with repeatable accuracy.

How Capsule Molds Work (Step-by-Step Process)

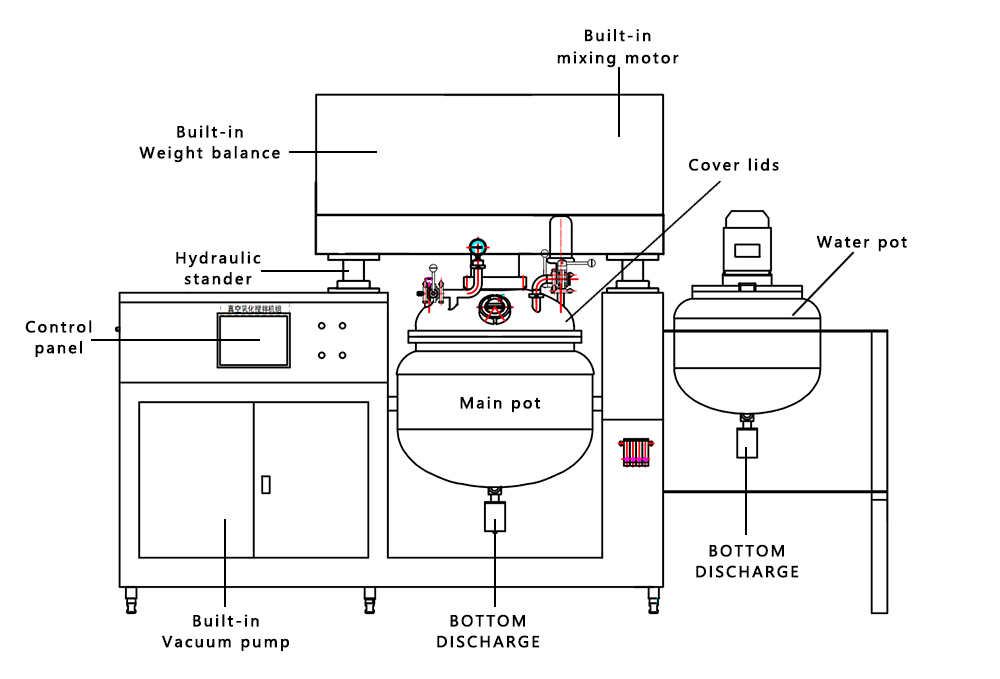

Capsule molds are part of a controlled capsule-forming process where gelatin (for traditional capsules) or HPMC (Hydroxypropyl methylcellulose) is shaped into the capsule shell. The mold controls the final size, wall thickness, and fit of the two capsule parts.

Step 1: Loading Raw Material

The process begins by preparing the capsule-forming material. Manufacturers use gelatin or HPMC, depending on product and regulatory needs. The material is heated and mixed with purified water until it becomes a liquid solution.

Color, opacity, or brand-specific printing ingredients may be added at this stage. The solution must reach the correct viscosity and temperature, as even small variations can affect capsule thickness and uniformity.

Step 2: Dipping Pins Into the Capsule Mold

Capsule molds consist of several rows of stainless-steel pins shaped to the exact inner dimensions of capsule bodies and caps. These pins serve as the “form” on which the shell will build. During dipping, the mold pins slowly descend into the gelatin or HPMC solution.

When they are lifted back out, a thin film of material sticks to the surface of each pin. The thickness of the shell depends on controlled variables like withdrawal speed, temperature, and viscosity.

Step 3: Rotation + Drying

Once dipped, the mold pins rotate slowly while moving through a drying tunnel. This rotation ensures the solution spreads evenly around each pin and prevents gravity from forming thick spots.

Warm filtered air then flows through the capsules, evaporating moisture and allowing the shell walls to harden. If the drying is too fast, the capsules may crack. However, if the drying is too slow, they may deform. This is why temperature and airflow are tightly controlled.

Step 4: Stripping and Cutting

After drying, the hardened capsule shells are ready to be removed. The shells are stripped off the mold pins and transferred to a trimming mechanism.

During trimming, the capsule body and capsule cap are cut to their exact lengths. At this point, each piece is still separate. The longer piece becomes the body here, while the shorter one becomes the cap.

Step 5: Joining Capsule Body + Cap

Ultimately, the capsule body and cap are transported to a joining station. A special mechanism partially fits the cap over the body, leaving it open just enough to receive powder or pellets during filling later.

Manufacturers perform visual inspection and mechanical tests to ensure that the locking groove and snap-fit mechanism are working properly. A proper lock ensures that capsules stay sealed after filling.

FAQs

1. How are capsule molds cleaned?

Molds are cleaned using non-corrosive detergents and deionized water, followed by ultrasonic cleaning or high-pressure air drying. The cleaning frequency is defined in a validated SOP to prevent residue buildup.

2. What is the difference between lab-scale and industrial capsule molds?

Lab-scale molds are smaller, often semi-automatic, and used for R&D or pilot batches. Industrial molds are high-capacity, automated, and integrated with continuous drying and polishing systems.

3. How does temperature and humidity affect mold performance?

Improper humidity causes gelatin to dry unevenly, while high temperatures can deform mold coatings. Controlled environmental conditions are essential for consistent film formation.

Build Strong Capsule Production With the Right Equipment

Capsule molds are the foundation of capsule manufacturing, but molds alone cannot create the final product. Without the right equipment, dipping, drying, cutting, joining, and filling, even the best mold can’t do its job.

And this is where Finetech shines.

We are one of the leading suppliers of pharmaceutical equipment, trusted by manufacturers in over 100 countries. Whether you need capsule filling machines or complete capsule production solutions, our equipment is engineered to meet GMP requirements.

Get an instant quote today and transform your capsule manufacturing process!