ResearchGate reports that the stability of a dosage form relies on the choice of packaging material. Among various options, many types of vials are widely used in modern healthcare. These storage containers protect the drug integrity against environmental factors.

For centuries, vials have played a significant role in pharmaceutical development. Initially, they were crafted from glass for its purity and inertness. Over time, innovations introduced polymer-based vials for complex drug formulations. This blog helps you choose the right vial based on your needs.

Classification by Material

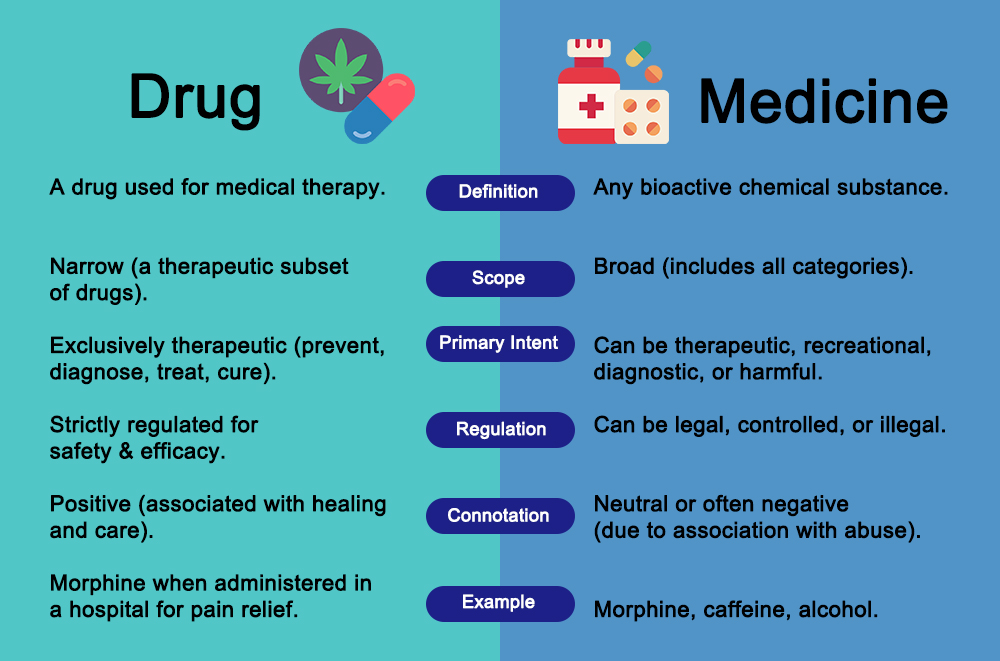

The choice of drug storage material ensures the efficacy of pharmaceutical products. To deliver quality dosage forms, understanding various types of vials is essential. It allows developers to choose the most suitable packaging for specific drug formulations. Below is the overview of two commonly used containers for medicine packaging.

Glass Vials:

Glass vials are the oldest pharmacy storage containers. They serve as a versatile choice due to the compatibility of glass with a diverse range of medications. It includes injectables, vaccines, biologics, and sensitive formulations. Within glass vials, there are three main categories commonly used in laboratory and commercial settings.

Selecting from these types of vials relies on the drug’s sensitivity, storage conditions, and sterilization requirements. Here is an overview:

Type I (Borosilicate)

Borosilicate glass is widely used for both injection and non-injection purposes. These Type I vials offer superior quality due to their chemical composition. The presence of at least 5% of boric oxide enhances their chemical resistance and thermal stability.

Studies have shown that most of the parenteral drugs are stored in Type I glass containers due to their high hydrolytic tolerance. In addition to that, this material can withstand repeated sterilization and extreme temperature variations. This feature makes them a preferred choice for photo-sensitive pharmaceutical applications. Due to their unique characteristics, these containers are more expensive.

Type II (Treated Soda-Lime)

The Type II containers are typically made of soda lime glass. A chemical treatment on the inner surface is performed to improve its water resistance. As they’re not as strong as Type I, these vials are used for moderately sensitive drugs.

Also, they lack high temperature tolerance. So, they are only deployed for less reactive formulations. It includes acidic, neutral, or alkaline drug products. However, they’re a more cost-effective option compared to borosilicate glass containers.

Type III (Soda-Lime)

These vials are made of soda lime without any chemical treatment. They have the least substance resistance among the three glass vials. Being highly economical, they provide minimal protection against water or environmental factors.

In the pharmaceutical industry, these types of vials are typically used for non-parenteral or less sensitive drugs.

Plastic Vials:

In addition to glass, other types of vials used in healthcare are made of plastic. This packaging material offers ease of handling due to its lightweight nature. Also, it offers break resistance, providing enhanced safety during transportation.

The plastic containers are typically made from advanced polymers. The detail is in the following:

- COP(Cyclo-Olefin Polymer): Being chemically stable, COP vials are suitable for sensitive formulations. They offer moisture and gas barrier properties to maintain the potency of drugs. Moreover, these plastic containers hold optical clarity for easy inspection of the contents. It’s significantly helpful for quality control in pharmaceutical production.

- COC(Cyclo-Olefin Copolymer): COC provides enhanced thermal stability and flexibility instead of COP. These polymers can tolerate temperature fluctuations during storage or shipping. They are often preferred for therapeutic drugs where consistent quality is required.

- PET(Polyethylene Terephthalate): Being shatterproof and cost-effective, PET containers are a popular choice for high-volume applications. They are suitable for oral liquids or powders that do not require extreme chemical or thermal resistance. Also, these plastic vials offer compatibility with automated filling and capping systems.

Material Types of Vials | Sub Category | Key Properties | Uses |

Glass Vials | Type I (Borosilicate Glass) | Highest stability and resistance to moisture and temperature | Handles sensitive Injectibles, or vaccines |

Type II (Treated Soda-Lime Glass) | Chemically treated for improved hydrolytic tolerance | Best for moderate sensitive parenteral drugs | |

Type III (Soda-Lime Glass) | Low resistance, economical | Used for non-injectibles, and less sensitive products | |

Plastic Vials | COP | Highly transparent, Strong moisture resistance | Good for sensitive drug formulations |

COC | Enhanced thermal stability | Suitable for dosage forms where consistent quality matters | |

PET | Shatterproof, lightweight and budget-friendly | Oral liquids, powders and large scale-applications |

Classification by Use

Beyond material differences, vials can also be classified according to their intended applications. Let’s discuss these types briefly.

Lyophilization Vials

These pharmacy containers are specially developed for freeze-drying processes. During lyophilization, liquid formulations turn into powders for extended shelf life. Here, vials hold these drug products for maximum protection. They endure extreme temperature shifts to prevent contamination.

Serum Vials

Serum vials are commonly used for injectable drugs, vaccines, and biological products. They are designed to keep medicines sterile and safe throughout storage. These vials are typically sealed with rubber stoppers and aluminum caps for secure closure.

Diagnostic Vials

Diagnostic vials are specialized containers that store samples for diagnostic procedures. They ensure product integrity to provide precise test results. Often made from high-quality glass or plastic, they come in different volumes as per requirements.

Vial Classification by Use | Primary feature | Uses |

Lyophilization Vials | Tolerate extreme temperatures, extend shelf life | Freeze-drying processes |

Serum Vials | Sterile, maintain safe dosing | Parenteral drugs, vaccines and biological products |

Diagnostic Vials | Ensure sample quality, available in various sizes | Storage and transport of samples for testing |

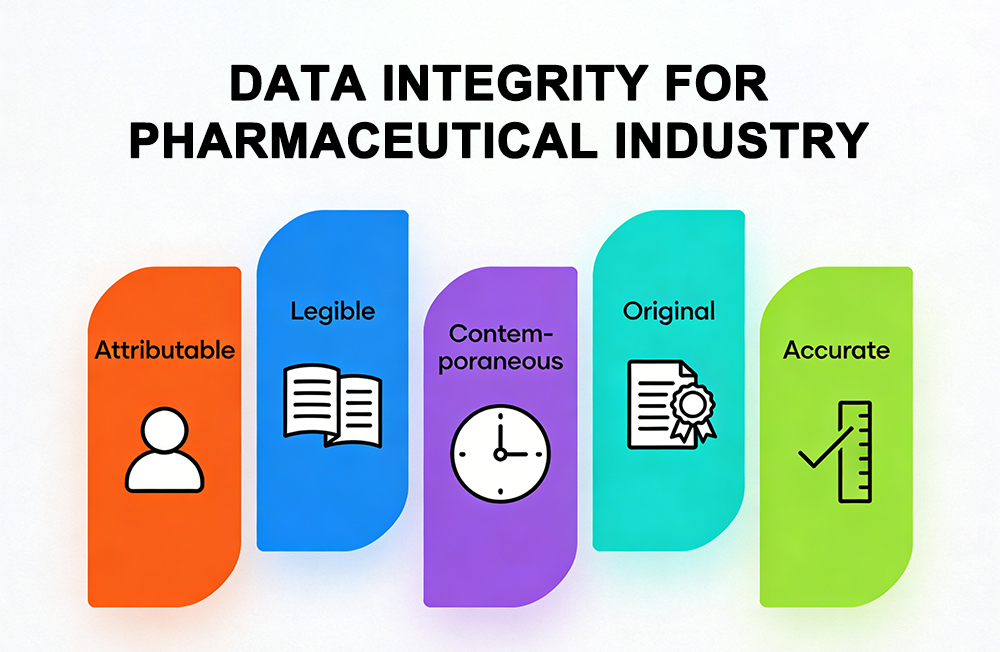

Types of Vials| Standards & Regulations

Regulatory frameworks define the performance requirements for different types of vials used in healthcare. The drug packaging you select must comply with international standards for quality assurance. The United States Pharmacopeia (USP) is a body that sets rules for promoting the integrity of therapeutic products. For example,

- USP <660>: It specifies the requirements for glass containers used for pharmaceutical packaging. It focuses on explaining their properties and application areas.

- USP <1661>: This standard offers guidelines to assess the suitability of plastic packaging systems. It highlights the polymer descriptions and their usage for patient safety.

- ISO 8362: This document enlists the global standards for glass vials. It covers areas such as dimensions, mechanical strength, and resistance properties.

- Container Closure Integrity (CCI): A strong CCI is vital to maintain sterility and prevent leaks. It verifies the ability of vial closures (stoppers, seals, caps) to alleviate contamination risks.

Challenges & Innovations

Despite their efficient role for medicinal storage, vials also present some challenges. They can affect drug safety and overall product quality. To address these issues, smart solutions have been introduced in the market. Here are some problems and their solutions:

Common Issues

- Breakage: Some types of vials are prone to cracking or shattering during manufacturing or storage. For example, glass containers can break easily during transportation. It results in product loss and additional costs.

- Leachables: In some cases, the materials from containers may migrate into drug formulations. It compromises product purity and can affect patient safety.

- Delamination: Thin flakes or inner layers can peel off from the vials. These particles can contaminate injectable formulations and pose health risks.

Smart Solutions

- Advanced Coatings: To alleviate the above challenges, advanced coatings on vial surfaces are developed. They prevent delamination issues and maintain drug purity. Also, they protect the container case and enhance its durability.

- Smart Vial: These innovative solutions are equipped with digital sensors. With traceability features, you can monitor storage conditions and detect tampering. In this way, they offer more reliable options for the safety of dosage forms.

Conclusion

Durable medicinal packaging is significant for drug integrity. For that, various types of vials offer effective storage options. Each container has its own set of properties to ensure safe dosing. The ultimate decision depends on your formulation requirements.