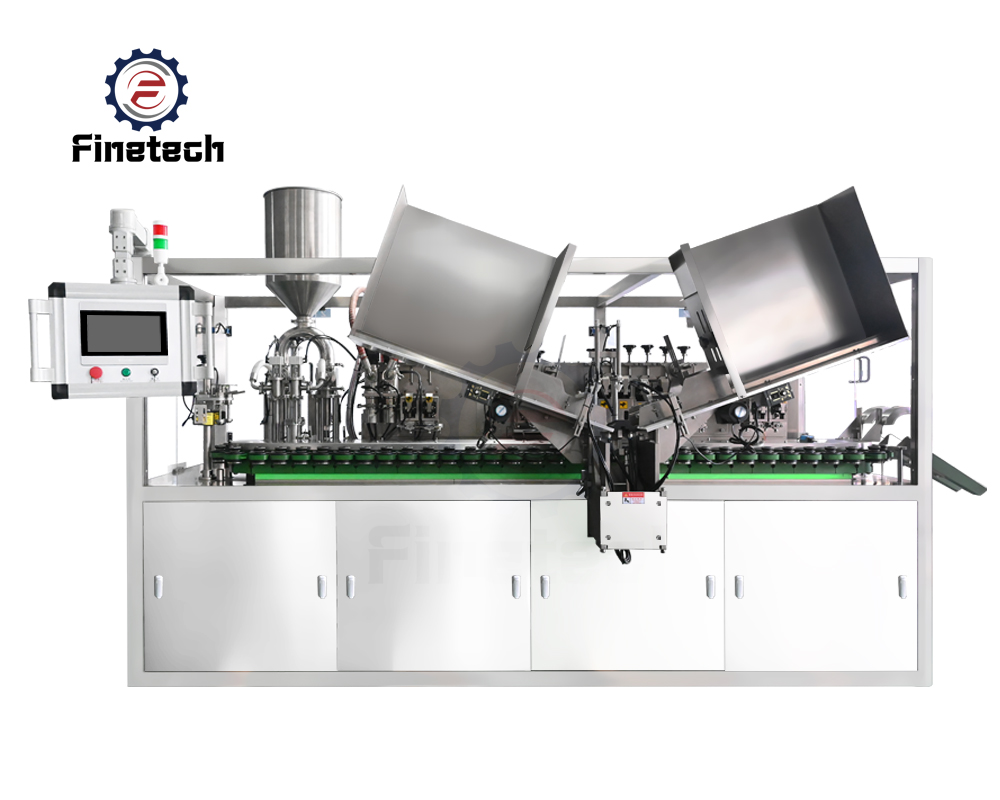

FT-80 Metal/Aluminum Tube Filling and Sealing Machine

This product specializes in filling and sealing metal and aluminum tubes, with servo-driven technology ensuring high-precision filling accuracy within ±0.1g. It meets the high-speed, bulk production demands of cosmetic and ointment manufacturing lines. Real-time laser inspection ensures consistent sealing quality, while the modular quick-release design allows for fast cleaning in just 30 minutes. It is ideal for high-end brand production environments with strict requirements for cleanliness and production efficiency.

Need a Custom Quote?

Or More information About this product? Contact our sales stuff today!

Key Features

Technical Data

Machine Details

FAQ

Application Product Types

1. Utilizes advanced servo drive technology with a filling accuracy of ±0.1g, significantly surpassing standard industry precision levels.

2. Features an innovative dual-station synchronous operation mode, boosting production efficiency by 60% compared to single-station equipment, meeting the demands of high-speed mass production.

3. Equipped with an intelligent tube diameter self-adaptation system, which automatically accommodates tubes ranging from 3 to 80mm in diameter without manual adjustment, reducing changeover time.

4. Built-in laser inline inspection system continuously monitors sealing quality, promptly detecting and rejecting defective products to reduce waste rates.

5. Modular quick-release structure combined with food-grade stainless steel materials enables rapid cleaning within 30 minutes.

| Model | FT-80 Metal/Aluminum Tube Filling Sealing Machine |

| Operation speed | 80 tubes/min/(max) |

| Filling volume | 1 – 300ml |

| Filling precision | ≤±0.5% |

| Suitable tube length | 210mm(customizable) |

| Suitable tube diameter | 10 – 50mm |

These machines are ideal for a wide range of viscous products, including:

Pharmaceuticals: Ointments, gels, creams, pastes (e.g., antiseptic, analgesic, hydrocortisone).

Cosmetics & Personal Care: Face masks, hair colorants, sunscreen, hand creams, lotions.

Industrial & Food: Adhesives, sealants, lubricants, grease, food pastes (e.g., tomato paste, cake icing).

The standard process involves a sequence of automated stations:

Tube Loading: Empty tubes are manually loaded into a magazine or automatically fed.

Orientation & Cap Tightening: Tubes are aligned, and caps are pre-tightened if loose.

Bottom Folding & Sealing (for laminated tubes): The tube tail is folded and crimped/sealed.

Filling: A precision piston pump injects the product through the tube nozzle.

Plunger Insertion (for collapsible tubes - optional): A plunger is inserted into the open end.

Top Folding & Sealing: The open end is neatly folded and crimped (single or double fold).

Coding/Imprinting: Date, batch number, or expiration date is printed on the seal.

Ejection: Finished tubes are discharged onto a conveyor or into a collection bin.

Single-Tube (Indexing/Carousel): Tubes are processed one at a time on a rotating station. Ideal for low to medium production (e.g., 20-60 tubes per minute), lower cost, and easier changeovers.

Multi-Tube (Linear/In-Line): Multiple tubes are filled simultaneously in a linear motion. Designed for high-speed production (e.g., 80-300+ tubes per minute), higher efficiency, but more complex and expensive.

Double Fold (Roll Crimp): Most common for aluminium tubes. Creates a hermetic, leak-proof seal by folding the tube end twice.

Single Fold: Used for some plastic and laminate tubes.

Heat Sealing: Exclusive to laminate/plastic tubes. Uses heated jaws to melt the inner layer together.

Yes, but with changeover parts. You typically need to change the:

Tube holders/clamps

Filling nozzle (must match tube orifice)

Folding claws and sealing jaws

Pump piston size (for large volume changes)

Changeover time varies from 15 minutes to an hour depending on machine design.

These terms refer to the same technology. The filling nozzle is inserted deep into the tube, and product is dispensed as the nozzle rises. This prevents air entrapment, which is crucial for product stability (oxidation), accuracy, and a professional finish.

Design Features: Look for machines with stainless steel contact parts, CIP (Clean-in-Place) systems, smooth surfaces, and easy disassembly.

Procedure: Implement strict SOPs for changeovers and cleaning between batches.

Environment: Consider machines with protective covers or ones rated for cleanroom installation if needed.

Reputable suppliers offer on-site installation & commissioning training for machine operators, mechanics, and electricians. This covers operation, changeover, basic troubleshooting, and safety procedures.

Cream Lotion Products

Skincare products: Such as face cream, hand cream, body lotion, sunscreen, and BB cream.

Pharmaceuticals: Topical creams (e.g., hormonal and antibacterial creams).

Industrial supplies: Including polishing compounds and metalworking emulsions.

Gel Products

Personal care products: Such as shampoo, body wash, hand sanitizer gel (some in tube packaging), and oral care gel.

Medical gels: Including ultrasound coupling gel, burn treatment gel, and mouth ulcer gel.

Electronics gels: Such as thermal conductive silicone paste.

Paste Products

Toothpaste: The most classic application, accounting for the vast majority of global production.

Medicated ointments: Topical ointments such as anti-itch cream (e.g., Diphenhydramine) and erythromycin ointment.

Cosmetic pastes: Including facial cleanser, mask cream, hair dye cream, and depilatory cream.

Industrial pastes: Such as lubricating grease, sealants, silicone adhesive, two-part adhesive (AB glue), and solder paste.

Food pastes: Examples are mustard, ketchup, chili sauce, and thick jam (partially packaged in tubes).

Semi-Fluid/Viscous Liquid Products

Art supplies: Such as oil paint, watercolor, and acrylic paint.

Construction and decorative materials: Including silicone sealant, tile grout, and caulking compound.

Food products: Such as icing and cake decorating cream.