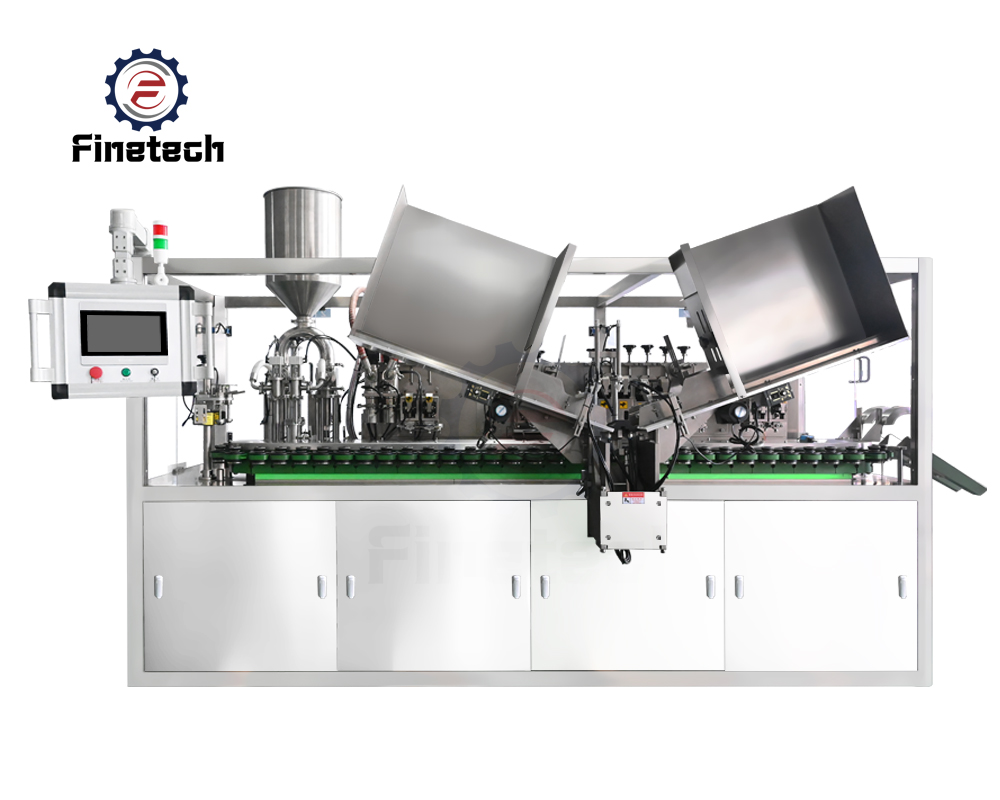

FT-09 Automatic Ultrasonic Tube Filling and Sealing Machine

The ultrasonic tube filling and sealing machine is specifically designed for the cosmetics, pharmaceutical, food, household chemical industries, and uses advanced ultrasonic welding technology. It features a compact structure, intelligent operation, strong and aesthetically pleasing seals, and high-speed performance. Designed for filling and sealing metal and aluminum tubes of different diameters, it efficiently handles automated production of liquids, pastes, and powders. This makes it an ideal solution for high-quality production of modern tube-packaged products.

Need a Custom Quote?

Or More information About this product? Contact our sales stuff today!

Key Features

Technical Data

Machine Details

FAQ

Application Product Types

1. Servo control technology allows precise adjustment of the filling volume via a touchscreen, ensuring consistent filling across all tubes and guaranteeing product uniformity. The tube chamber height can be easily adjusted based on tube length, and the external inverted feeding system ensures cleaner, more convenient loading.

2. Equipped with mechanically linked photoelectric sensors, offering a precision error of less than 0.2mm to minimize color deviation between the tube and registration mark, ensuring sealing quality. The system integrates photoelectric, electrical, and pneumatic controls — no tube, no fill; low air pressure alarms; and automatic machine stop in case of tube errors or safety door openings, ensuring safe operation.

3. The triple-jacket instant heater uses internal air heating, which protects the tube’s outer design while achieving strong and visually appealing seals. A PLC controller and color touchscreen provide programmable control and an intuitive interface. With a wide range of system parameters available, users can easily monitor machine status, enhancing reliability and ease of use.

| Model | FT-09 Automatic Ultrasonic Tube Filling Sealing Machine |

| Operation speed | 18 – 28 units/ min |

| Filling volume | 6 – 60ml、10 – 120ml、25 – 250ml |

| Filling precision | ±1% |

| Suitable tube length | 70 – 210mm |

| Suitable tube diameter | 16 – 50mm |

| Tube feeding system | Equipped with an upper tube station and a pick-and-place station, it can efficiently transport hoses to the orientation station |

It uses high-frequency (ultrasonic) mechanical vibrations (typically 20-40 kHz) from a piezoelectric transducer. The horn (sonotrode) presses the tube against the sealing anvil. The vibrations create friction and localized heat at the tube's plastic layers, melting and fusing them together under pressure to form a hermetic seal without external heat.

Cold process: Minimal heat generation protects sensitive contents (e.g., pharmaceuticals, biologics, gels).

Hermetic, particle-free seals: No burn-through or charring.

Speed: Seals in typically 0.2-1 second.

Energy efficiency: Consumes power only during sealing.

Consistency: Highly repeatable process.

Laminated plastic tubes (e.g., with PE, PP, or Aluminum foil barrier layers), co-extruded plastic tubes, and some monolayer PE tubes. Common in cosmetics, pharmaceuticals, medical, food, and industrial products.

No, standard ultrasonic sealing is for plastic or plastic-laminate tubes. Pure aluminum tubes require thermal conduction sealing. Laminate tubes with a thin aluminum foil layer inside are common and sealable.

Unsupported foils, PVC, PET, PTFE, or materials with high melt temperatures/bad friction properties. Always consult the manufacturer for material compatibility tests.

Typically years under normal use. Life depends on material (titanium alloy), operating amplitude, and maintenance. Avoid scratches and overtightening. Cracks or pitting require immediate replacement.

Yes, most models are designed for inline integration with conveyors, sensors, and PLCs for automatic tube feeding and discharge.

Basic operation training is recommended for setup, parameter adjustment, and troubleshooting to ensure seal quality and machine longevity.

Cream Lotion Products

Skincare products: Such as face cream, hand cream, body lotion, sunscreen, and BB cream.

Pharmaceuticals: Topical creams (e.g., hormonal and antibacterial creams).

Industrial supplies: Including polishing compounds and metalworking emulsions.

Gel Products

Personal care products: Such as shampoo, body wash, hand sanitizer gel (some in tube packaging), and oral care gel.

Medical gels: Including ultrasound coupling gel, burn treatment gel, and mouth ulcer gel.

Electronics gels: Such as thermal conductive silicone paste.

Paste Products

Toothpaste: The most classic application, accounting for the vast majority of global production.

Medicated ointments: Topical ointments such as anti-itch cream (e.g., Diphenhydramine) and erythromycin ointment.

Cosmetic pastes: Including facial cleanser, mask cream, hair dye cream, and depilatory cream.

Industrial pastes: Such as lubricating grease, sealants, silicone adhesive, two-part adhesive (AB glue), and solder paste.

Food pastes: Examples are mustard, ketchup, chili sauce, and thick jam (partially packaged in tubes).

Semi-Fluid/Viscous Liquid Products

Art supplies: Such as oil paint, watercolor, and acrylic paint.

Construction and decorative materials: Including silicone sealant, tile grout, and caulking compound.

Food products: Such as icing and cake decorating cream.