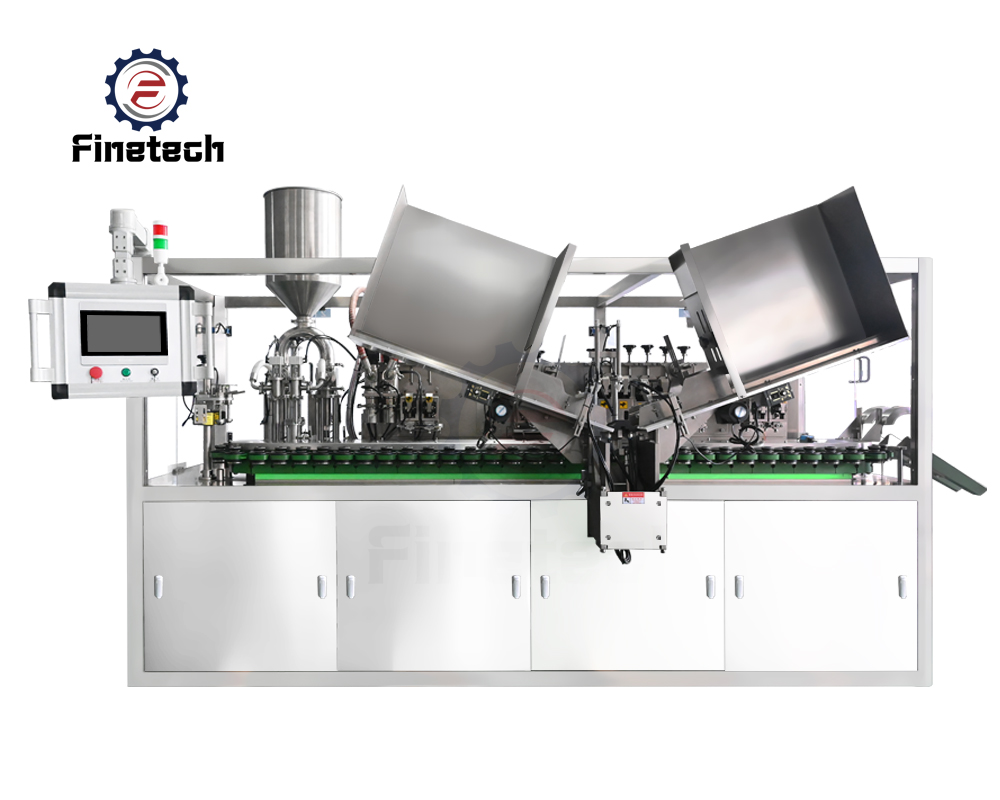

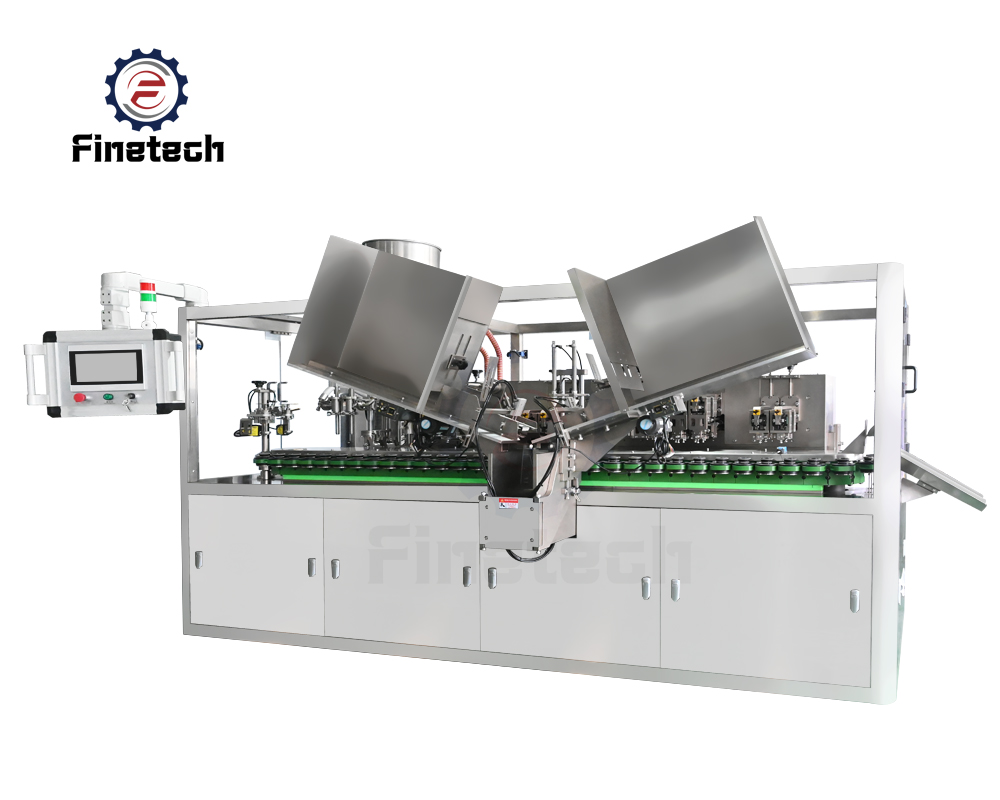

FT-150 Automatic Tube Filling and Sealing Machine

This product is specifically designed for high-volume production and features a high-speed rotary filling system, increasing output by 40% compared to traditional equipment. Its intelligent temperature-controlled sealing technology ensures smooth and secure sealing of tubes made from different materials such as metal and plastic, effectively preventing leakage. Designed for large-scale production of food sauces, personal care products, and more, it can seamlessly integrate with automated production lines to achieve efficient, stable, and scalable manufacturing.

Need a Custom Quote?

Or More information About this product? Contact our sales stuff today!

Key Features

Technical Data

Machine Details

FAQ

Application Product Types

1. Equipped with a high-speed rotary filling system, capable of filling and sealing up to 150 tubes per minute — a 40% increase in productivity compared to traditional equipment.

2. Features intelligent temperature control technology for precise sealing temperature regulation. Applied for tubes made of metal, plastic, and other materials. It ensures smooth, secure seals with excellent leak prevention.

3. Seamlessly integrates with automated production lines, providing a stable and efficient solution for large-scale manufacturing of products such as food sauces and personal care items.

| Model | FT-150 Tube Filling and sealing |

| Filling speed | 150 tubes/ min |

| Filling volume | 2 – 200ml |

| Filling precision | ≤±1% |

| Suitable tube length | 50 – 200mm |

| Suitable tube diameter | 10 – 35mm |

These machines are versatile and can handle a wide range of products, including:

Cosmetics: Creams, gels, lotions, toothpaste, hair color.

Pharmaceuticals: Ointments, gels, topical creams.

Food: Mayonnaise, sauces, pastes, condiments.

Industrial: Adhesives, lubricants, sealants.

Key Point: The machine must be compatible with the product's viscosity, abrasiveness, and chemical properties.

Most modern machines are multi-purpose and can handle:

Materials: Laminated (plastic/aluminum), plastic (PE, PP), aluminum, co-extruded tubes.

Shapes: Round, oval, or flattened oval tubes.

Sizes: Typically from 5ml to 500ml or more, depending on the machine model. Change parts (like tube holders and filling nozzles) are required for different sizes.

Speed varies by model and tube size. Common ranges are:

Entry-level/Single Lane: 30-60 tubes per minute (tpm).

Standard Multi-Lane: 60-120 tpm.

High-Speed: 150-400+ tpm.

Note: Speed is affected by product viscosity, tube size, and sealing method.

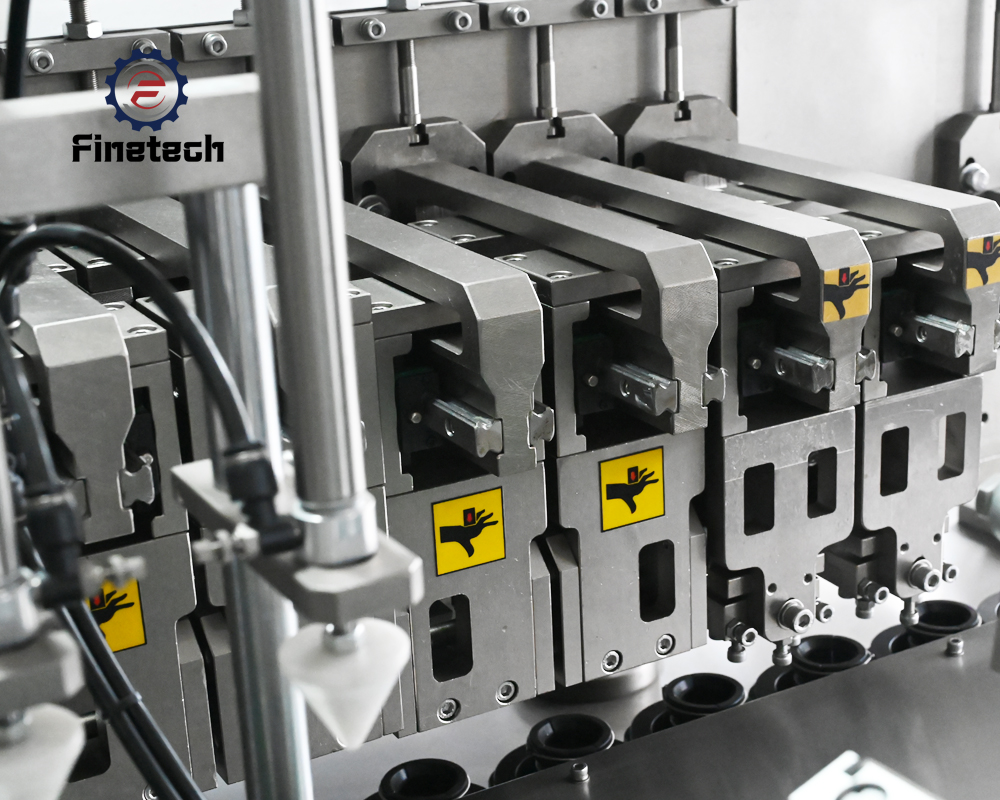

Changeover complexity varies. Modern machines feature Quick Changeover (QCO) systems. It involves changing the tube magazine, centering bell, filling nozzle, and sometimes the sealing jaws. With trained operators and proper tooling, changeover can take 30-90 minutes.

This is a critical feature for pharmaceutical and food-grade applications. Many machines offer CIP/SIP options for the product contact parts (filling pump, nozzle, hopper) to allow for cleaning and sterilization without complete disassembly. Always specify this requirement upfront.

With proper maintenance, installation in a good environment, and use of genuine spare parts, a high-quality automatic tube filler can reliably operate for 15-25 years or more.

Absolutely. Most manufacturers strongly recommend conducting factory acceptance tests (FAT) using your actual tubes and a sample product to verify performance, speed, and quality before shipment.

Possible causes: misaligned tube magazine, incorrect tube holder for the size, damaged or out-of-specification tubes, a fault in the transfer mechanism sensor.

Cream Lotion Products

Skincare products: Such as face cream, hand cream, body lotion, sunscreen, and BB cream.

Pharmaceuticals: Topical creams (e.g., hormonal and antibacterial creams).

Industrial supplies: Including polishing compounds and metalworking emulsions.

Gel Products

Personal care products: Such as shampoo, body wash, hand sanitizer gel (some in tube packaging), and oral care gel.

Medical gels: Including ultrasound coupling gel, burn treatment gel, and mouth ulcer gel.

Electronics gels: Such as thermal conductive silicone paste.

Paste Products

Toothpaste: The most classic application, accounting for the vast majority of global production.

Medicated ointments: Topical ointments such as anti-itch cream (e.g., Diphenhydramine) and erythromycin ointment.

Cosmetic pastes: Including facial cleanser, mask cream, hair dye cream, and depilatory cream.

Industrial pastes: Such as lubricating grease, sealants, silicone adhesive, two-part adhesive (AB glue), and solder paste.

Food pastes: Examples are mustard, ketchup, chili sauce, and thick jam (partially packaged in tubes).

Semi-Fluid/Viscous Liquid Products

Art supplies: Such as oil paint, watercolor, and acrylic paint.

Construction and decorative materials: Including silicone sealant, tile grout, and caulking compound.

Food products: Such as icing and cake decorating cream.