Have you ever wondered how pharmaceutical companies make sure every medicine is safe and reliable? Compliance is not just paperwork. It is a critical part of protecting patients and maintaining trust.

With it comes GxP in the pharmaceutical industry to regulate healthcare-related companies. These Good “x” Practice standards guide how medicines are developed, manufactured, and tested.

With that said, let’s explore what it is and why it matters for the pharmaceutical industry.

What Is GxP in the Pharmaceutical Industry?

GxP in the pharmaceutical industry refers to a set of quality guidelines and regulations that confirm medicines are safe, effective, and reliable. The term “GxP” stands for Good “x” Practice, where “x” can mean different areas such as pharmaceutical manufacturing, laboratory, or clinical trials.

These standards are recognized worldwide and are enforced by regulatory bodies like the FDA in the United States and the EMA in Europe.

The purpose of GxP is to make sure every stage of pharmaceutical development follows strict rules. By following these guidelines, companies can protect patients, reduce risks of contamination, and build trust with regulators.

Importance of GxP in the Pharmaceutical Industry

GxP is a framework that affects patients, companies, and regulators. Here’s why it matters for companies:

1. Ensures Patient Safety and Product Quality

At the heart of GxP is safety, as companies want medicines that actually work and don’t harm people. GxP makes sure every pill, injection, or vaccine is made carefully. It checks ingredients, production steps, and storage conditions as well.

If these steps are skipped, mistakes may occur, and patients may become ill or receive ineffective medication.

2. Protects Companies from Legal Risks and Recalls

Being compliant with GxP also protects organizations from significant legal and financial exposure. If companies fail to meet these standards, it can result in regulatory fines, product recalls, and damaged reputation.

For instance, in 2012, Johnson & Johnson recalled over 135 million units of bottles and admitted quality control issues. This shows how important it is to adhere to GxP standards to minimize such risks and product recalls.

3. Builds Trust with Regulators and Patients

Following GxP demonstrates commitment to quality and regulatory integrity. Regulatory bodies, including the FDA and EMA, rely on these standards to evaluate operational practices.

Compliance signals to both regulators and patients that processes are reliable and controlled. This trust is crucial, as it underpins market authorization, stakeholder confidence, and long-term brand credibility.

What Are the Core Elements of GxP in the Pharmaceutical Industry?

GxP is not a single standard. It is a set of complementary practices that cover different areas of pharmaceutical development and operations. Each element has a specific focus but works together to guarantee quality, safety, and compliance.

1. Good Manufacturing Practice (GMP)

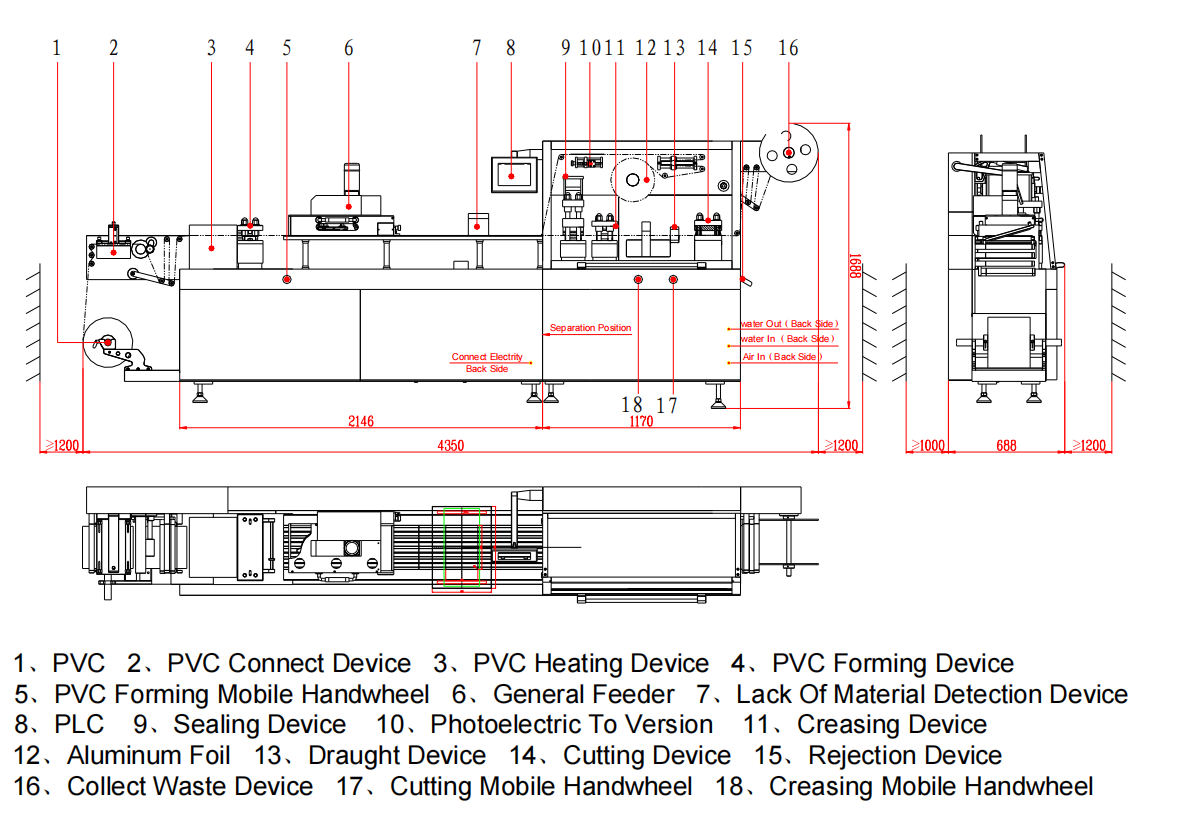

GMP is all about keeping pharmaceutical products in check and making sure they are consistently produced and controlled in accordance with quality standards. It covers every step, from sourcing raw materials to packaging and labeling.

This includes equipment calibration, staff training, documentation, and hygiene standards. Following GMP helps prevent contamination, errors, and variability between batches. In short, it is the foundation of reliable manufacturing.

2. Good Laboratory Practice (GLP)

GLP governs the planning, conduct, monitoring, and reporting of laboratory studies. It’s a guarantee that experiments, tests, and analyses are reproducible and accurate.

For instance, stability studies or chemical testing must follow GLP rules to produce trustworthy data. If you’re into research, you should be following these GLP standards.

3. Good Clinical Laboratory Practice (GCLP)

GCLP focuses on clinical trials, ensuring that studies involving human subjects are ethical, safe, and scientifically sound. It sets standards for study design, informed consent, data integrity, and monitoring.

Compliance with GCLP protects participants while generating reliable data from regulatory review. It’s crucial to follow GCLP standards as they show that new medicines are tested properly before reaching the market.

4. Good Documentation Practice (GDocP)

GDocP verifies that all records, reports, and data are accurate, complete, and traceable. Moreover, it states that every action, observation, and decision must be documented clearly by the companies.

Proper documentation supports audits, inspections, and regulatory submissions. In pharma, GDocP prevents data integrity issues and strengthens overall GxP compliance.

Benefits of Following GxP in the Pharmaceutical Industry

Here’s what happens when companies comply with GxP practices:

1. Reduced Recalls and Compliance Risks

Following GxP significantly lowers the risk of product recalls. Every step, from production to testing, is monitored and documented. This way, companies can catch issues before products reach patients.

Regulatory inspections also become smoother, as processes and records are compliant and transparent.

2. Improved Product Consistency and Safety

GxP is responsible for making sure that every batch of medicine meets the same high standards. Standardized processes and quality controls prevent variability. This consistency is essential for patient safety and therapeutic effectiveness.

Whether it’s tablets, injections, or vaccines, GxP practices guarantee that each product performs as intended.

3. Enhanced Reputation with Regulators

Compliance with GxP shows that a company is committed to providing high-quality products. Regulators, such as the FDA or EMA, view compliant companies as reliable and responsible.

Customers and healthcare providers also gain trust in the brand, knowing that products are consistently safe and effective. Remember, a reputation built on GxP compliance can lead to faster approvals.

4. Long-Term Cost Savings

While implementing GxP requires an initial investment, it ultimately reduces costs over time. Implementing GxP can help save costs by preventing recalls, avoiding regulatory fines, and minimizing pharmaceutical production errors.

In the long run, GxP creates a more sustainable and predictable business model, making compliance a smart decision.

Common Challenges in GxP Compliance

While the benefits are clear, several obstacles can make compliance difficult. Knowing these challenges helps organizations prepare and address them effectively. Let’s find out which challenges you might have to face during compliance.

1. Complex Regulatory Requirements

GxP standards are intricate and vary across different regions and regulatory bodies. For instance, organizations operating globally must navigate the complexities of aligning with multiple regulatory frameworks simultaneously.

This complexity discourages companies and causes confusion. However, non-compliance can be extremely costly. The Ponemon Institute also reported that organizations that fail to conduct internal compliance audits face an average per capita non-compliance cost of $1,275.

2. Data Integrity Issues

Although reliable data is paramount in GxP compliance, data integrity issues still persist. These concerns are also highlighted in multiple warning letters issued by the FDA.

For instance, in 2021, data integrity problems were cited in 65% of FDA warning letters. This highlights the prevalence of persistent data integrity issues and underscores the importance for companies like yours to maintain accurate entries.

Strengthen Your Pharma Operations with GxP

Today, it’s essential to follow GxP in the pharmaceutical industry. It reduces risk, improves consistency, and builds trust with both regulators and customers. The process may seem complex, but with the right guidance, it becomes manageable and rewarding.

And that’s what we do at Finetech.

We offer complete production lines and customized machinery to support your compliance and operational goals.

Contact Finetech now to explore solutions that will strengthen your compliance!

FAQs

1. How can small pharma companies implement GxP?

Small pharma companies struggle with limited resources. Therefore, if you want to implement GxP, begin with high-risk areas, such as manufacturing and clinical trials. Once those areas are compliant, you can roll out the same practices across the rest of the organization.

2. What should a company do if a GxP violation occurs?

If a GxP violation occurs, take immediate action. Investigate the root cause, document findings, and implement corrective and preventive actions. Inform regulators if required and review processes to prevent recurrence. Quick, transparent action can reduce penalties and protect patient safety.