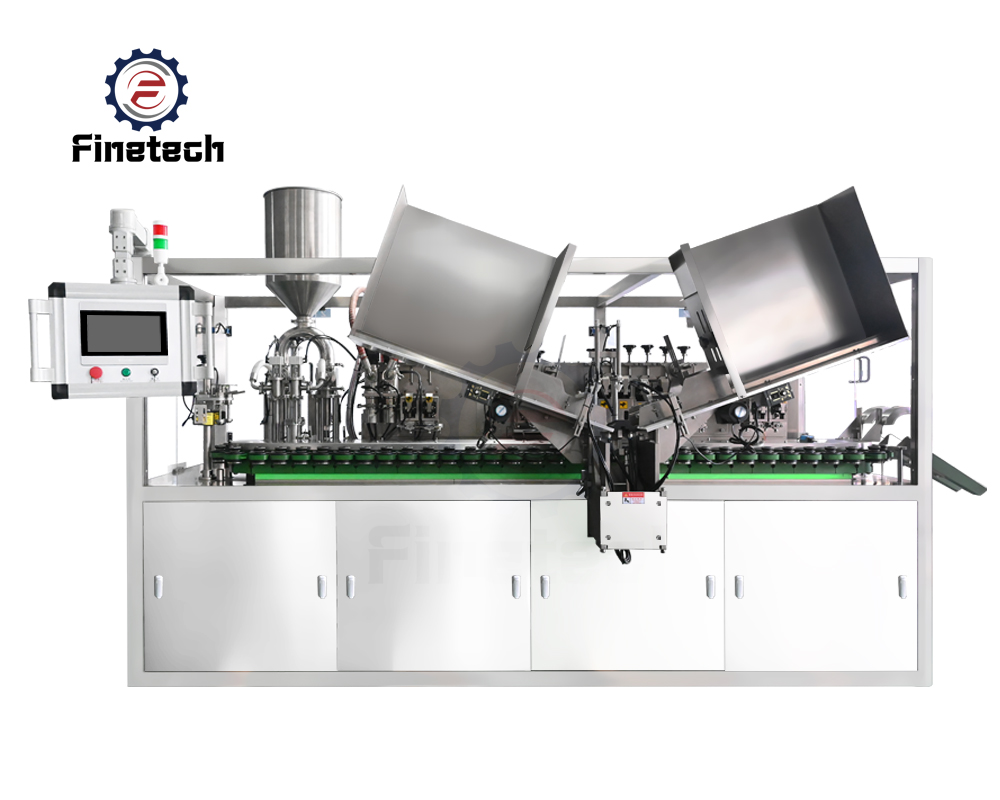

FT-60A/80A/120A Laminated Tube Filling and Sealing Machine

This Laminated Tube Filling and Sealing Machine is an efficient and precise filling solution designed to produce tube-packaged goods. It is applied to industries such as cosmetics, pharmaceuticals, food, and household chemicals. The automated production system increases efficiency, reduces labor costs, and supports different tube diameters and materials to meet diverse packaging requirements. The equipment features a modular design. It is CIP (Clean-in-Place) friendly, and complies with GMP and hygiene standards, helping enterprises achieve efficient, precise, and flexible large-scale production of tube-packaged products.

Need a Custom Quote?

Or More information About this product? Contact our sales stuff today!

Key Features

Technical Data

Machine Details

FAQ

Application Product Types

1, Servo Control Technology:The servo-driven system allows for precise adjustment of the filling volume via a touchscreen interface, ensuring consistent dosing across all tubes. The tube chamber height is easily adjustable based on tube length, while the external reverse-feed system makes the loading process cleaner and more efficient.

2. The mechanical linkage with photoelectric sensors ensures high precision, with an error margin of less than 0.2mm, minimizing color deviation between the tube and the registration mark.

3. Integrated photoelectric, electrical, and pneumatic control system:No tube no filling; low air pressure alarm; the machine stops automatically if there is a tube error or if the safety door is opened. The triple-jacketed instant heater uses internal air heating, preserving the tube’s exterior design while delivering a strong and aesthetically pleasing seal.

4. Fault alarm system:The machine stops automatically in case of overload, ensuring production safety. Equipped with a PLC controller and a color touchscreen, allowing programmable control and easy operation.

| Model | FT-60A | FT-80A | FT-120A |

| Operation speed | 60units/min(max) | 80units/min(max) | 120units/min(max) |

| Filling volume | 5-250ml | 5-250ml | 5-250ml |

| Filling precision | ≤±1% | ≤±1% | ≤±1% |

| Suitable tube length | 50-210mm | 50-210mm | 50 – 150mm |

| Suitable tube diameter | ø13-50mm | ø13-50mm | 12 – 35mm |

| Tube feeding system | obliguely hanging type automatic liningup tube feeding storehouse | obliguely hanging type automatic liningup tube feeding storehouse | obliguely hanging type automatic liningup tube feeding storehouse |

It's an automated machine that seals the open end of laminated plastic tubes (used for packaging creams, gels, pastes, etc.) using heat and pressure to create an airtight, leak-proof closure.

Typically two types:

Single-fold seal: One fold of the tube end (standard)

Double-fold seal: Two folds for extra security (common for pharmaceuticals)

Multi-layer laminated tubes (plastic/foil laminates), aluminum tubes, and plastic tubes. Machines often have different sealing jaws for different materials.

Most machines require changing:

Tube clamping jaws

Sealing jaws

Possibly the loading magazine

Modern machines often have quick-change systems with digital calibration.

Temperature (typically 120-200°C depending on material)

Pressure (sealing force)

Dwell time (contact time)

Cooling time (for consistent seal)

Common causes:

Temperature too low: Insufficient melting of laminate layers

Insufficient pressure: Layers not properly bonded

Contaminated jaws: Oil, residue preventing proper heat transfer

Wrong jaw type for material

Depending on use, typically 6-12 months for continuous operation. Signs for replacement:

Pitting or uneven surface

Inconsistent seals despite calibration

Visible wear patterns

Machines range from:

30-60 tubes/min (standard)

80-120 tubes/min (high-speed)

150+ tubes/min (ultra-high-speed)

Cream Lotion Products

Skincare products: Such as face cream, hand cream, body lotion, sunscreen, and BB cream.

Pharmaceuticals: Topical creams (e.g., hormonal and antibacterial creams).

Industrial supplies: Including polishing compounds and metalworking emulsions.

Gel Products

Personal care products: Such as shampoo, body wash, hand sanitizer gel (some in tube packaging), and oral care gel.

Medical gels: Including ultrasound coupling gel, burn treatment gel, and mouth ulcer gel.

Electronics gels: Such as thermal conductive silicone paste.

Paste Products

Toothpaste: The most classic application, accounting for the vast majority of global production.

Medicated ointments: Topical ointments such as anti-itch cream (e.g., Diphenhydramine) and erythromycin ointment.

Cosmetic pastes: Including facial cleanser, mask cream, hair dye cream, and depilatory cream.

Industrial pastes: Such as lubricating grease, sealants, silicone adhesive, two-part adhesive (AB glue), and solder paste.

Food pastes: Examples are mustard, ketchup, chili sauce, and thick jam (partially packaged in tubes).

Semi-Fluid/Viscous Liquid Products

Art supplies: Such as oil paint, watercolor, and acrylic paint.

Construction and decorative materials: Including silicone sealant, tile grout, and caulking compound.

Food products: Such as icing and cake decorating cream.