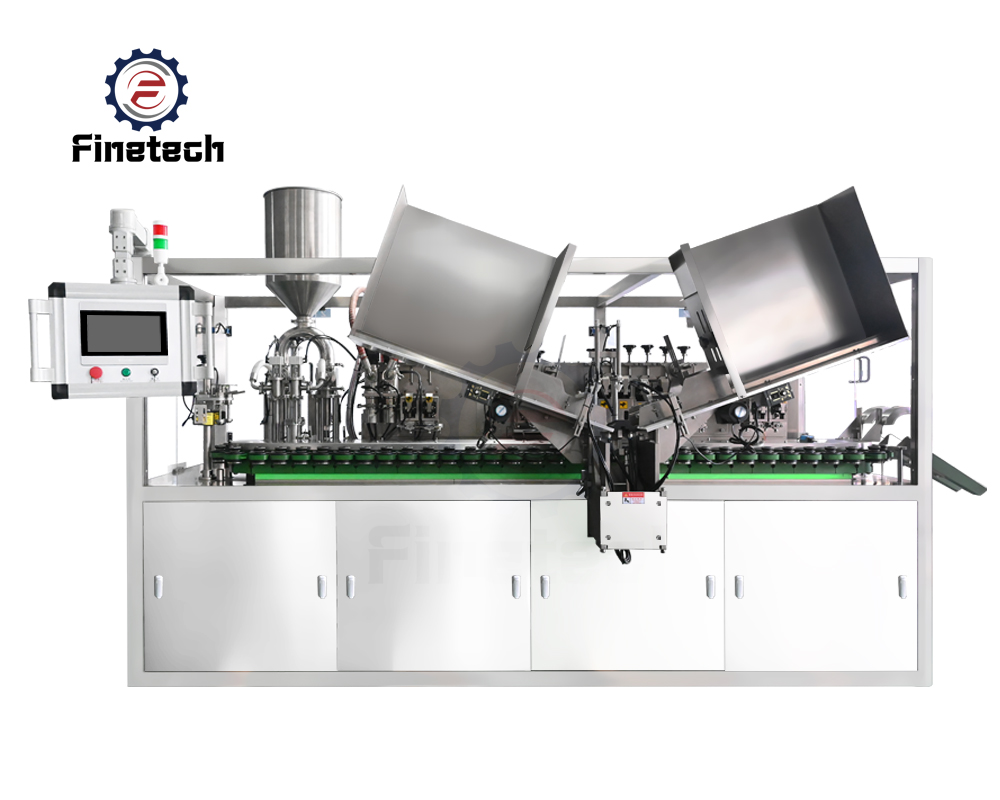

FT-30 Manual Tube Filling and Sealing Machine

This manual tube filling machine is renowned for its flexible operation, and is specifically designed for small to medium batch production, laboratory research, and customized applications. Its compact and portable design supports quick replacement of filling heads and sealing molds, making it compatible with tubes of various diameters. Whether for sample prototyping or small-scale specialty product manufacturing, it enables precise filling and sealing with ease — making it an ideal choice for startups and R&D teams.

Need a Custom Quote?

Or More information About this product? Contact our sales stuff today!

Key Features

Technical Data

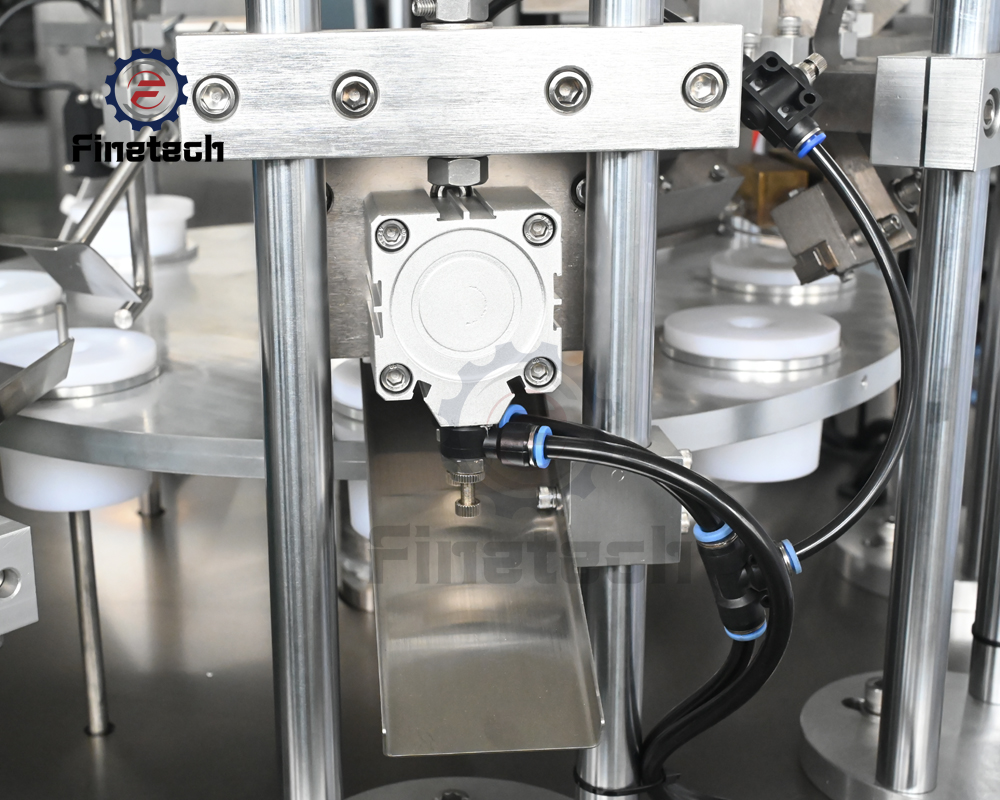

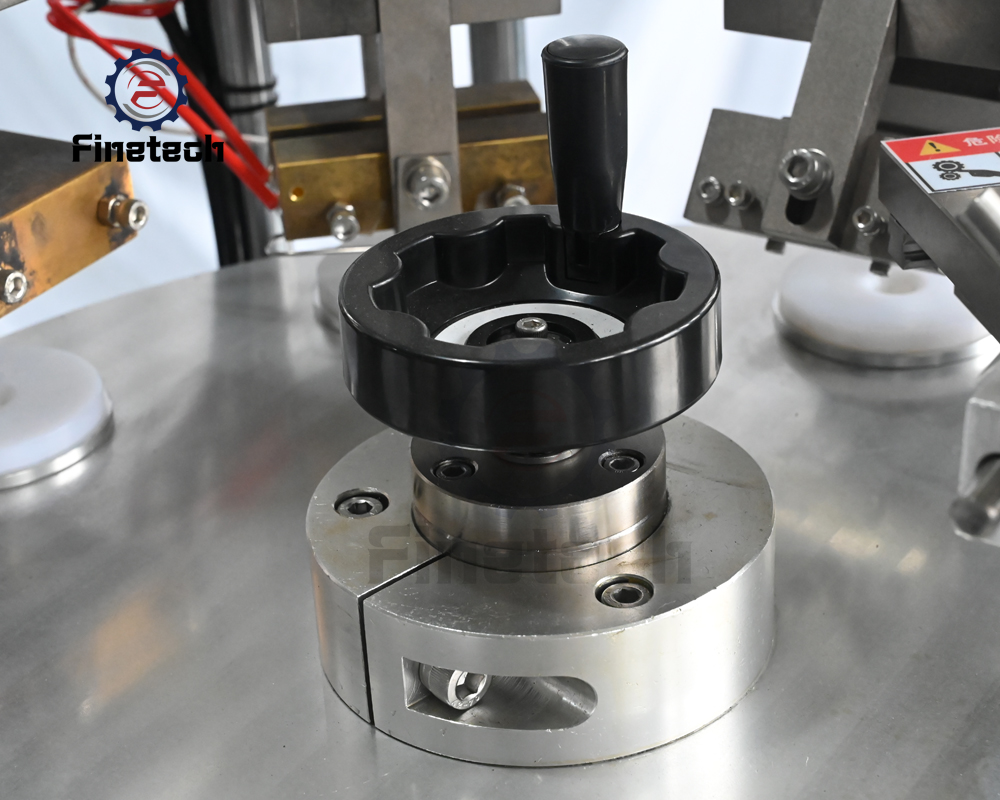

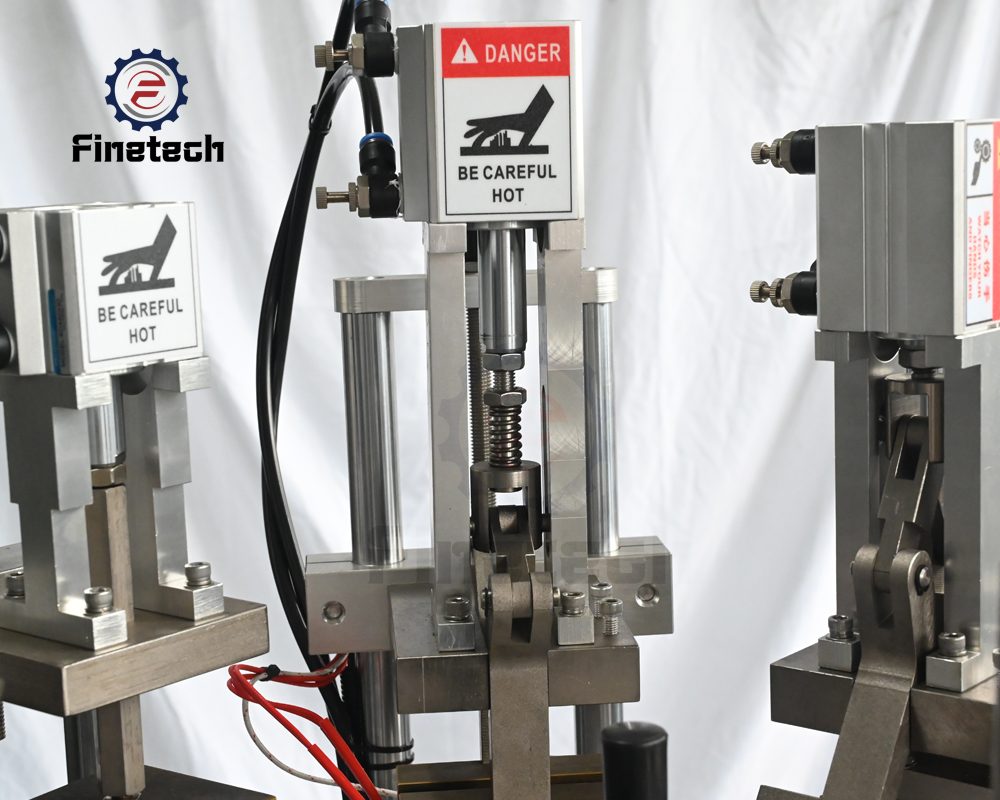

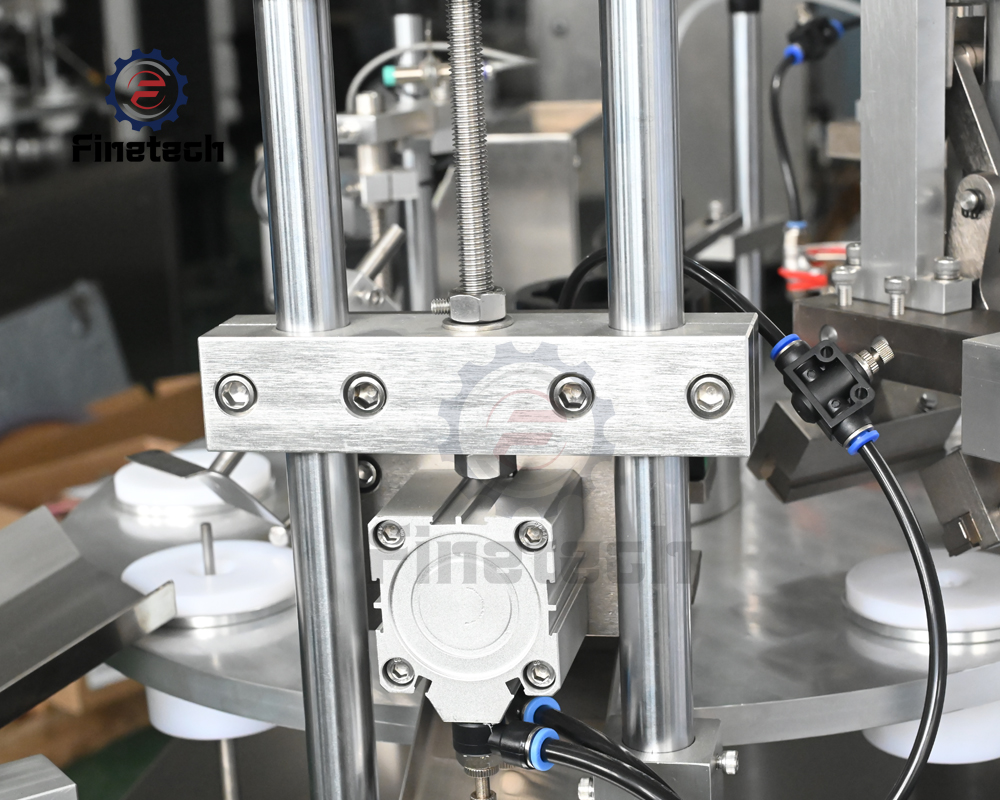

Machine Details

FAQ

Application Product Types

Manually adjustable filling volume, ranging from 0.5 to 300ml, allowing precise control to meet diverse product requirements.

Compact and portable design, with support for quick replacement of filling heads and sealing molds. Compatible with tubes of various diameters and is easy to operate — even beginners can quickly get started.

Tailored for small to medium batch production, lab research, and personalized customization. It offers high efficiency and low cost for sample prototyping and the production of small-batch specialty products.

| Model | FT-30 Manual Tube Filling and Sealing Machine |

| Operation speed | 30-60units/min |

| Filling volume | 0.5 – 300ml |

| Filling precision | ±1% |

| Suitable tube length | 50 – 200mm |

| Suitable tube diameter | 10 – 50mm |

It's a hand-operated device used to fill semi-solid or viscous products (creams, ointments, pastes, adhesives) into collapsible tubes. It requires physical effort to operate the lever/piston mechanism.

Ideal for small-scale production, R&D, pharmacies, cosmetics startups, compounding labs, and low-volume specialty products (e.g., hand creams, salves, dental paste, industrial adhesives).

Works with plastic, laminate, or metal tubes (e.g., aluminum). Tube diameter and length must match the machine's specifications.

Accuracy depends on operator skill and product viscosity but typically achieves ±1–3% variation. Adjustable pistons or stroke length control volume.

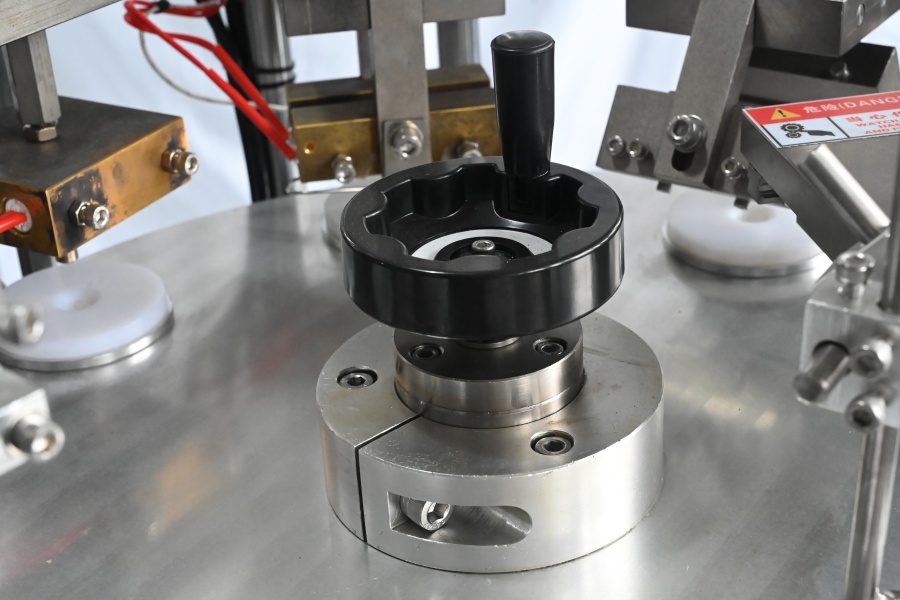

Adjust the piston stroke via a threaded mechanism, calibration screw, or interchangeable cylinders/pistons. Test-weigh filled tubes to fine-tune.

Yes, with changeable tube holders/clamps and nozzles. Check the machine's size range (usually 10–50 mm diameter).

Ensure tube is properly clamped and nozzle matches tube neck size. Check for worn seals or misalignment.

Typically $200–$1,500 USD, depending on build quality, brand, and accessories.

Cream Lotion Products

Skincare products: Such as face cream, hand cream, body lotion, sunscreen, and BB cream.

Pharmaceuticals: Topical creams (e.g., hormonal and antibacterial creams).

Industrial supplies: Including polishing compounds and metalworking emulsions.

Gel Products

Personal care products: Such as shampoo, body wash, hand sanitizer gel (some in tube packaging), and oral care gel.

Medical gels: Including ultrasound coupling gel, burn treatment gel, and mouth ulcer gel.

Electronics gels: Such as thermal conductive silicone paste.

Paste Products

Toothpaste: The most classic application, accounting for the vast majority of global production.

Medicated ointments: Topical ointments such as anti-itch cream (e.g., Diphenhydramine) and erythromycin ointment.

Cosmetic pastes: Including facial cleanser, mask cream, hair dye cream, and depilatory cream.

Industrial pastes: Such as lubricating grease, sealants, silicone adhesive, two-part adhesive (AB glue), and solder paste.

Food pastes: Examples are mustard, ketchup, chili sauce, and thick jam (partially packaged in tubes).

Semi-Fluid/Viscous Liquid Products

Art supplies: Such as oil paint, watercolor, and acrylic paint.

Construction and decorative materials: Including silicone sealant, tile grout, and caulking compound.

Food products: Such as icing and cake decorating cream.