Packaging is an important part of pharmaceutical products, enhancing their visual appeal and protecting them from degradation. It ensures that drugs are protected from contamination and counterfeiting, and attracts customers to make a purchase. As many as 72% of American consumers say their purchasing decision is impacted by the packaging design. If you are a pharmaceutical manufacturer exploring the various types of packaging of tablets, this article is for you. Continue reading!

Different Types of Packaging of Tablets

The packaging of tablets or capsules is divided into two categories: primary and secondary. Let’s discuss both in detail so you can make informed decisions:

Primary Packaging

Primary packaging is actually the first layer that directly holds and protects the tablets or capsules. Here are the different types of packaging of tablets you can try:

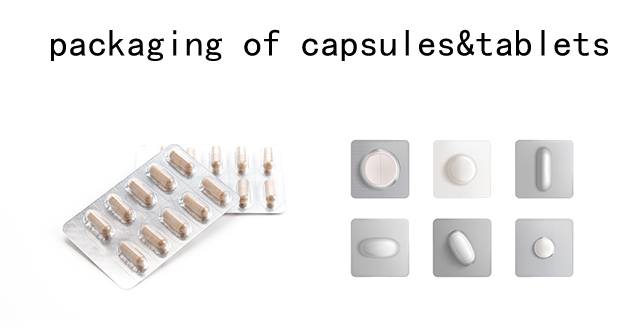

Blister Packaging

Blister packaging consists of a pre-formed plastic cavity or blister bonded to a lidding material that contains single-unit doses. The product is easy to see, and you can also ensure proper protection from heat and moisture.

It’s also suitable for new drugs that have a conflict risk with traditional packaging materials. Common materials used in blister packs include PVC, PET, and aluminum. The following are some blister packaging methods:

- Thermoforming: Typically, blister packs are made via thermoforming, in which a plastic film or sheet is heated to make it flexible or pliable before it’s shaped by high pressure. A mold is formed that’s cooled at room temperature to maintain the given shape. This method is best suited for small products, such as tablets, since it’s quick, effective, and forms clear and strong barriers.

- Cold Forming: As the name implies, cold forming doesn’t involve heat. Rather, the laminate plastic is molded into a cavity by applying immense pressure. It’s preferred for products that require long-term storage and are highly sensitive.

Bottles

Bottles are often made of glass and plastic (polyethylene or polypropylene) and are used to securely hold tablets and capsules. They can also feature childproof safety mechanisms and are amber-colored to protect light-sensitive medications from degradation or other chemical reactions.

The best part about these types of packaging of tablets is that they allow easy handling, shipping, and display on shelves. Here’s an overview of the step-by-step working of a bottle packaging machine:

- Empty bottles are fed into the machine using a belt conveyor or an unscrambler for small bottles.

- Load the hopper with a sufficient quantity of tablets or capsules. When the machine gets turned on, tablets start releasing from the hopper onto vibratory plates. The vibration motor creates a shaking sensation that propels the tablets to segregate, and they fall into individual units on the trays.

- Now the serialized tablets fall into counting compartments where they are counted via electric detection systems and then filled into the nozzle.

- As the sensors detect the presence of a bottle, they dispense a certain amount of tablets into the bottle. It’s then capped and discharged from the machine for further processing.

Strip Packs

Strip packaging is a method in which drugs, whether in tablet or capsule form, are enclosed in a continuous strip of flexible material. The strip is usually made of plastic or aluminum and protects the drugs from elements, ensuring their high efficacy.

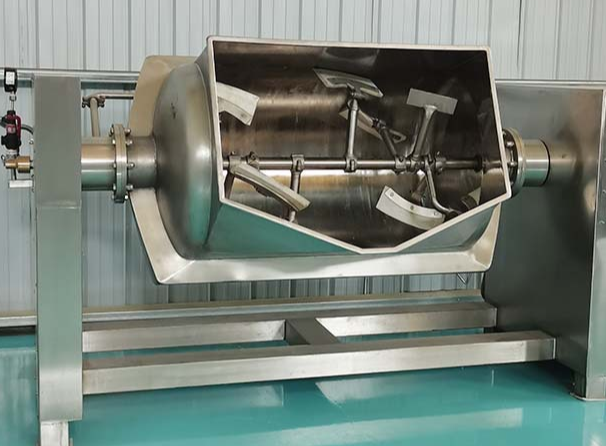

Multiple types of packaging machines for tablets are available, including Foil Strip Packing Machines, Alu-Alu Strip Packing Machines, and Double Aluminum Strip Packing Machines. Let’s look at their general working:

- Start by turning on the machine and placing the tablets to be packed on the feeder tray, which is then moved to the conveyor belt for further processing.

- Now, a roller comes into play that ensures that the products lie flat as they move along the belt to the sealing station.

- At the sealing stop, there’s a packaging material holder that releases material through the packaging shaft.

- Two continuous webs of heat-sealable films, such as aluminum foil or plastic, are fed into the machine. The films are drawn over a sealing area where tablets are gradually released between them.

- The heated roller often presses the two films together, creating an airtight seal that protects the products from moisture and light.

- Strips are then cut and perforated for easy consumption..

Secondary Packaging

Secondary packaging is actually the outer protective layer that houses the primary packaging. It’s often a carton or cardboard box that prevents damage during shipping and handling. The following are the types of packaging of tablets in this regard:

- Cartons and Paperboard Boxes: If you want to store blister packs of tablet bottles, then cartons and paperboard boxes are ideal choices. They are made of durable materials and provide an extra layer of protection during shipping. In addition to that, you have a space for graphic design where you can add your company logo and other product details, such as ingredients and usage instructions.

- Shrink Wraps: Shrink wraps are heat-shrinkable plastic films wrapped around a pharmaceutical product. They have a snug, custom-fit seal around the product, providing tamper evidence and maintaining a clean and sterile environment.

Importance of Different Types of Packaging of Tablets

Now that you are aware of the different types of packaging of tablets, let’s explore the many benefits they offer to pharma manufacturers:

Enhanced Product Protection

One of the benefits of using different types of packaging of tablets is that it protects the drug throughout its lifecycle. It protects the medication against environmental contaminants, including heat, moisture, light, microbes, and oxygen.

On top of this, packaging safeguards it against physical damage during transportation and storage. All this significantly extends the lifespan of the tablet and maintains the stability and efficacy of pharmaceutical ingredients.

Regulatory Compliance and Quality Assurance

Since pharmaceuticals greatly impact a person’s health and overall wellness. Therefore, it’s strictly under regulatory frameworks imposed by bodies such as the FDA and EMA. When you package the tablets efficiently, it ensures that your products are child-resistant, serialized, and traceable.

You can also use the secondary packaging to communicate essential information, including dosage instructions and expiration dates. This much transparency allows you to stay compliant with industrial standards and avoid penalties.

Increased Brand Image and Sales

The pharmaceutical industry is becoming crowded with each passing day. Standing out in the competition becomes a hassle. However, with effective secondary packaging, your company can really shine.

For instance, you can use the packaging as a canvas to mention your brand name and logo, reinforcing the brand identity.

In addition, it’s your chance to communicate dosage, ingredients, instructions, and warnings. Customers feel informed and start trusting the business, leading to increased sales.

FAQs

How to choose the right types of packaging for tablets?

When choosing the right types of packaging for tablets, you should consider factors like drug sensitivity, patient convenience, and overall cost of the material.

Why is Alu-Alu packaging considered the best barrier protection?

Alu-Alu packaging is considered the best barrier protection because it creates an impermeable layer that prevents moisture, oxygen, and light from penetrating.

What type of packaging is most eco-friendly?

Paper-based cartons and recyclable plastic bottles are considered the most eco-friendly types of packaging for tablets.

Conclusion

It’s important to understand the different types of packaging of tablets to ensure you choose the right one for your needs. Wondering where you can get top-notch pharmaceutical packaging machinery for your daily operations? Get in touch with us today and streamline all your packaging tasks!