Blending is one of the most crucial steps in manufacturing. It ensures that every dose of medicine has the right balance of ingredients for consistent quality.

Why does this matter?

Because there are many different types of blenders in the pharmaceutical industry, companies end up buying the wrong one.

So, if you’re unsure which ones are available and what’s best for your production line, read on.

Key Takeaways: 7 Types of Blenders in the Pharmaceutical Industry

- V-Blender: Uses a twin-shell design that gently rotates to achieve uniform powder distribution.

- Double Cone Blender: Features a conical body that promotes efficient mixing for dry powders and granules.

- Bin Blender: Allows blending directly inside the storage container, reducing product transfer and contamination risks.

- Ribbon Blender: Uses counter-moving helical ribbons to handle large batches of powders with even mixing.

- Paddle Blender: Designed with flat paddles that fold and agitate materials, ideal for cohesive or slightly moist blends.

- Vertical Cone Blender: Provides smooth and controlled motion that protects delicate ingredients during mixing.

- Fluid Bed Processor: Performs mixing, drying, and granulation within one chamber for improved processing efficiency.

7 Types of Blenders in the Pharmaceutical Industry

Let’s explore the seven types of blenders in the pharmaceutical industry for you to find the perfect one for yourself.

| Name | Best For | Weaknesses |

| V-Blender | Gentle mixing of dry powders and delicate APIs. | Slow for sticky/cohesive powders. |

| Double Cone Blender | Uniform tumble mixing, easy discharge, and large free-flowing powders. | Longer mixing time and is less effective for wet or sticky materials. |

| Bin Blender | Flexibility, reduced handling, large batches, and ease of transfer. | More expensive fixtures and possibly less gentle for delicate materials. |

| Ribbon Blender | Large batch dry powders or wet-paste blends, and faster convective mixing. | High shear, possible heat generation, and cleaning can be harder. |

| Paddle Blender | Fragile powders, gentle folding, and less particle damage. | Slower mixing. Not suitable for heavy wet granulation or coatings |

| Vertical Cone Blender | Gentle mixing of fragile products, minimal damage, and heat-sensitive products. | More complex design, higher cost, and slower than high-shear for some mixes |

| Fluid Bed Processor | Drying + mixing + coating, and for high throughput. | High investment and not suitable for all powders. |

1. V-Blender (V-Type Tumble Blender)

The V-blender is one of the most common machines found in a pharmaceutical plant. It looks like two arms joined in a “V” shape, and when it turns, the powders keep flowing and folding over each other.

This simple movement is enough to give a smooth and even mix. Manufacturers like it because it doesn’t damage delicate powders, and it’s easy to clean after use. That’s why, in 2023, V-blenders held the most noticeable share of the pharmaceutical blender market.

How it works

- Powders are loaded inside the V-shaped chamber.

- The blender slowly rotates and causes the materials to split and merge.

- This repeated action mixes everything until it looks uniform.

- After the set time, the material is discharged for the next step.

This blender is the ideal choice for manufacturers when dealing with dry powders or granules that shouldn’t be subjected to excessive force. Smaller batch sizes or fragile ingredients usually fit well here.

2. Double Cone Blender

Sometimes, the simplest designs prove to be the most useful, and the double cone blender is a prime example. With its two cones joined at the center, it creates a rolling motion that allows powders to shift naturally.

There aren’t many moving parts to worry about, which makes it both reliable and low-maintenance for everyday use.

How it works

- Powders are poured into the cone chambers.

- The chamber rotates and makes the contents tumble and roll.

- Material keeps moving end to end until it blends smoothly.

- Once complete, the mix is released through a bottom valve.

The double cone blender shines when the powders are free-flowing and don’t clump together. It’s used mainly by manufacturers who want a gentle blend without overcomplicating things. Since it’s easy to operate, it fits perfectly into setups.

3. Bin Blender (IBC/Tote Blender)

Instead of a fixed mixing chamber, the bin blender takes a different approach by letting the container itself do the blending. Powders are loaded into a bin, locked into place, and then the whole bin is rotated.

By using this clever approach, manufacturers can cut cleaning time, save effort, and even allow the same bin to be used for transport and storage.

How it works

- Ingredients are filled into a special bin.

- The bin is then attached securely to the blender’s rotating arm.

- As the bin turns, powders move and tumble inside.

- When mixing ends, the bin is simply removed and taken forward.

These types of blenders are a top choice in large-scale production, where flexibility matters. Companies that are handling multiple products choose it because it reduces downtime and lowers the risk of cross-contamination.

4. Ribbon Blender

At first glance, the ribbon blender looks more like a big trough with blades than a typical mixer. Inside, it has long spiral ribbons that move in opposite directions, constantly pushing powders back and forth.

This design means the material doesn’t just tumble, it gets stirred and gives a faster and more uniform mix.

How it works

- Powders are placed into the horizontal trough.

- Inner and outer ribbons rotate in reverse directions.

- Material moves both inward and outward at the same time.

- The repeated flow ensures an even distribution.

Ribbon blenders are a smart choice when larger batches need to be handled quickly. They’re often used by companies working with granules or slightly moist powders that require more active mixing.

5. Paddle Blender

Where the ribbon blender uses spirals, the paddle blender takes a gentler approach with flat paddles that sweep through the powder. Each paddle lifts and folds the material, which gives a more careful blend.

It doesn’t rely on speed but on steady, controlled movement, which makes it a good option for fragile or sensitive ingredients.

How it works

- First, the operator loads ingredients into a horizontal chamber.

- Paddles then rotate slowly to lift and drop materials.

- The folding action helps distribute everything evenly.

- When finished, the mixture is discharged smoothly.

This blender is mostly chosen when powders need to be mixed without too much force. Therefore, if you’re working with heat-sensitive or fragile particles that could be damaged by a high-shear blender, a paddle blender is the ideal choice.

6. Conical Screw Blender (Vertical Cone Blender)

The conical screw blender looks different from most mixers. It has a tall cone with a long screw running inside, slowly lifting the material upward. At the same time, the screw itself rotates around the cone.

What makes this blender stand out is its gentleness, which makes it suitable for fragile or heat-sensitive materials.

How it works

- Ingredients are fed into the cone.

- A screw rotates and carries powder upward along the cone wall.

- Gravity lets the powder fall back to the center.

- Continuous upward and downward motion blends everything evenly.

A vertical cone blender is typically chosen for delicate APIs, vitamins, or nutrients that cannot withstand rough mixing. It’s also used for very large batches where slow and steady is better than fast and harsh.

7. Fluid Bed Processor

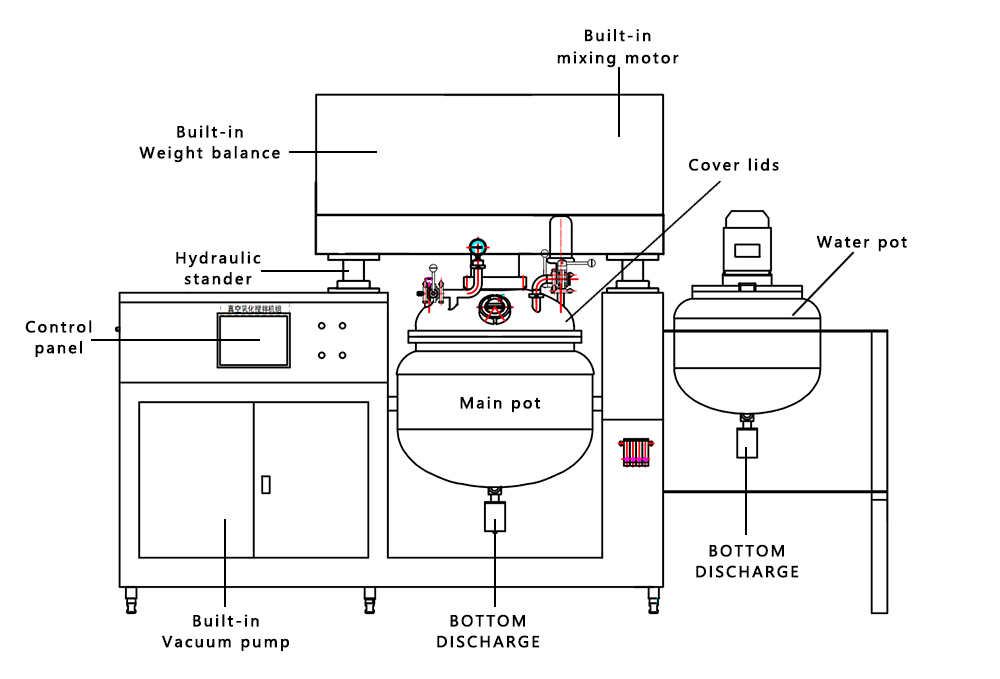

The fluid bed processor isn’t just a blender; it’s a multipurpose machine. This machine works by pushing hot air from beneath a perforated bed, which causes powders or granules to lift and float like they’re in a fluid.

In some cases, you can even spray liquid binders or coatings during the process. That makes it incredibly versatile because it can blend, dry, or coat in one system.

How it works

- Initially, the raw ingredients are placed in the fluid bed chamber.

- Heated air is blown from below, which makes particles rise and fall.

- Powders or granules circulate like a fluid and mix as they move.

- Liquid spray can be added for coating or granulation, then dried evenly.

Fluid bed processors are most valuable in large-scale production where speed and uniformity are crucial. They’re used for drying wet granules after high shear mixing, for coating pellets with APIs, or for making granules directly.

FAQs

1. What is the difference between a mixer and a blender in pharmaceuticals?

A mixer generally combines wet materials, while a blender is used to mix dry powders or granules.

2. What types of materials can be blended in a V-Blender?

It is ideal for dry powders, granules, and crystalline materials that require uniform blending without pressure or shear.

3. Can a Ribbon Blender mix cohesive or sticky materials?

Yes, with proper design and speed adjustment, it can handle slightly moist or cohesive blends.

Upgrade to Reliable Blending Power

When you look at the different types of blenders in the pharmaceutical industry, it’s clear that no single design fits every need. Some are made for fragile ingredients, while others are built to handle larger, more demanding batches.

Choosing the right one can be challenging with the numerous options now available. For that, Finetech takes center stage.

We offer a range of pharmaceutical blenders to meet every production requirement. Whether for gentle mixing or large-scale output, our blenders ensure accuracy, reliability, and lasting performance.

Contact Finetech today for a free quote!

Recommend Readings:

What Is Ribbon Blender and How Does It Work?

What is V Cone Blender? A Complete Guide to Industrial Mixing Equipment.