In the pharmaceutical industry, a medicine is only effective if it’s well protected. Many life-saving drugs are sensitive to moisture, oxygen, and light, which can quickly reduce their quality.

This is why Alu-Alu blister packaging is a non-negotiable choice for protecting sensitive medications. Its unique, all-aluminum construction provides an unparalleled barrier, ensuring a product’s integrity and shelf life from the factory to the patient.

Keep reading this guide if you want to know what Alu-Alu blister packaging is, its material composition, and its benefits for your business.

What is Alu Alu Blister Packaging?

Alu-Alu blister packaging is a high-performance blister packaging technique, primarily used in the pharmaceutical industry. The name “Alu-Alu” is a short form of “Aluminum-Aluminum.” This is because both the base and lidding on packaging are made from an aluminum-based film.

This packaging is known for providing an excellent barrier against moisture, oxygen, and light to highly sensitive medicines. It also extends their shelf life and maintains their potency and safety.

Material Composition of Alu Alu Packaging

Alu-Alu foil consists of a multi-layered structure, combining Oriented Polyamide (OPA), aluminum foil, and PVC film. These layers are stacked together using an adhesive to create a robust and highly protective material. We will examine each of them individually.

1. Oriented Polyamide Film (OPA)

Oriented Polyamide (OPA) film serves as the outermost layer of Alu-Alu packaging. It is a critical component due to its high puncture resistance and excellent mechanical strength. This durability protects the aluminum foil layer during the cold-forming process and from external damage during handling and transportation.

2. Aluminum Foil

The aluminum foil is the core of the packaging material. It creates a complete, impermeable barrier against moisture, oxygen, light, and other gases. This is the key reason why Alu-Alu is used for products that are highly sensitive to environmental factors.

3. PVC (Polyvinyl Chloride)

The innermost layer of the package is a food-grade Polyvinyl Chloride (PVC) film. This layer serves two key purposes. First, it adds bulk and rigidity to the laminate, which assists in the cold-forming process. Secondly, it acts as the heat-sealable layer and forms a secure bond between the lidding foil and the blister.

How Does Alu Alu Blister Packaging Work?

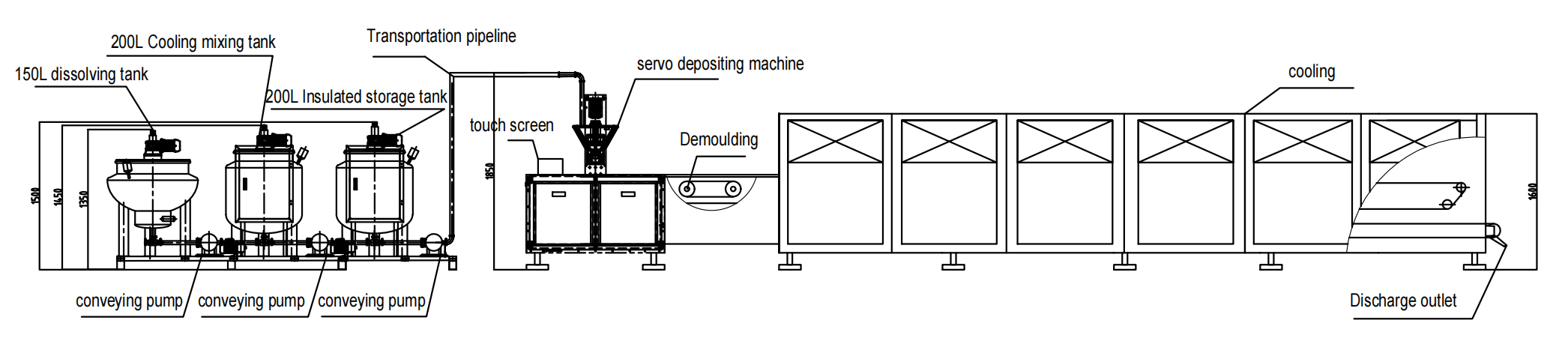

Alu-Alu blister packaging works through a specialized cold-forming process. Instead of heat, this method uses mechanical pressure to shape the material and protects the sensitive products’ insides. It’s a key distinction from standard plastic blister packs. This is how the entire process takes place:

Step #1: Cold Forming

The process begins with a multi-layered laminate film, which is made of nylon, aluminum, and PVC. This film is fed into a specialized blister packaging machine. Instead of being heated, a punch presses the laminate into a mold at room temperature. The mechanical pressure stretches the aluminum to form individual cavities without compromising the integrity of the foil barrier.

Step #2: Filling

Once the cavities are formed, they move to a filling station within the machine. The equipment precisely dispenses the product, such as tablets or capsules, into each of the pockets.

Step #3: Sealing

After filling, a layer of aluminum foil, known as the lidding foil, is placed over the filled blister sheet immediately. The two layers are then sealed together using heat and pressure. It creates a strong, airtight seal that permanently encloses the product and makes the package tamper-evident. The sealed packages are cut and prepared for distribution.

Key Features and Benefits of Alu Alu Blister Packaging

Drug integrity holds a critical importance in pharmaceutical manufacturing. Alu-Alu blister packaging is a preferred choice for this task due to its unique composition and properties. Here are some of the key characteristics that make Alu-Alu foil ideal for pharmaceutical packaging.

1. Superior Barrier Protection

Both the base and lidding of an Alu-Alu blister are made from aluminum. The dual-aluminum construction offers complete impermeability to water vapor, reducing the risk of moisture damage to the product. It also effectively blocks the excess oxygen and light from reaching the medication inside the package.

2. Extended Shelf Life

Alu-Alu packaging provides an exceptional barrier that protects medication from environmental degradation. The superior protection from moisture, oxygen, and light significantly extends the product’s shelf life. It is a critical feature, as many drugs can lose their potency and stability when exposed to humidity or heat.

Think of drugs and medicines for tropical climates that must withstand humidity. The all-aluminum construction of an Alu-Alu pack ensures the drug remains stable and potent. Whereas a standard plastic blister might allow moisture to affect the active ingredients’ performance over time.

3. Protection from Physical Damage

The multi-layered structure of Alu-Alu foil provides strong mechanical protection. A rigid, puncture-resistant design safeguards the medicine during transportation and handling. It ensures that individual tablets and capsules are not crushed or broken.

The packaging also serves as a great safety feature for kids. Since it is difficult to open without scissors or significant force, the sealed blister helps protect children from accidental swallowing or poisoning.

Uses of Alu Alu Blister Packaging in Different Sectors

Alu-Alu blister packaging is the gold standard for protecting sensitive products. While it’s most famous for its role in pharmaceuticals, the excellent barrier properties and tamper-evident design also make it useful in other fields.

1. Pharmaceutical Packaging

Pharmaceutical packaging is the most common use of Alu-Alu blister packaging. Because of the superior protection, it is widely used for:

- Antibiotics,such as those in the penicillin family, can lose their potency when exposed to moisture. Their chemical structure is vulnerable to hydrolysis. Alu-Alu packaging provides the dry, sealed environment needed to keep them stable.

- Cardiovascular Drugs: Cardiovascular medications such as nitroglycerin are highly sensitive to both light and moisture. The all-aluminium barrier protects them from degradation and sustains their stability.

- Anti-Hypertensives: Some blood-pressure medications are hygroscopic. This can cause the tablets to crumble or lose their effectiveness. The complete impermeability of Alu-Alu packaging keeps these drugs intact and potent.

2. Food Packaging

Different food items also benefit from the protection of Alu-Alu packaging. It is primarily used for products that require maintaining freshness, flavor, or texture over an extended period.

For example, it protects high-end chocolates from light and oxygen, and helps chewing gum maintain its texture and freshness. The packaging also keeps nuts and spices from spoiling due to oxidation and preserves their natural flavor.

3. Diagnostic kits

The medical field uses Alu-Alu packaging for diagnostic kits and medical devices that contain sensitive components. This may include reagents, test strips, or swabs that must remain sterile and fully functional until they are used.

Double-aluminum packaging makes sure that the components of the kit remain viable and protected until the moment of use.

Setting the Standard with Finetech’s Expertise

More than a simple container, Alu-Alu blister packaging is a sophisticated, high-performance solution. From its multi-layered composition to its cold-forming process, every aspect is designed for maximum barrier protection. While the price may seem high, the benefits, such as extended shelf life and maintained drug potency, far outweigh the initial cost.

Beyond the material itself, the packaging machinery you choose is equally critical. For an Alu-Alu blister packaging line that ensures quality and efficiency, choose Finetech.

Whether for medicines, food, or diagnostic kits, our specialized blister packaging solutions deliver reliable results. Contact Finetech and schedule a complimentary consultation with our experts to discover the ideal solution for your specific needs.

FAQs

1. What are some of the challenges associated with Alu-Alu packaging?

Alu-Alu packaging presents a few challenges. It is significantly more expensive than standard PVC-based blister packaging due to the cost of the materials and the specialized cold-forming machinery required. Second, its opaque nature prevents visual inspection of the product. This can be a drawback for both consumers and pharmacists.

2. Is Alu-Alu packaging recyclable?

Recycling Alu-Alu packaging is challenging due to its multi-layered structure. The different materials (nylon, aluminum, and PVC) are difficult to separate, so the packaging is generally not accepted in standard curbside recycling programs. Proper disposal often requires specialized industrial processes.

3. Why is Alu-Alu packaging also called Cold Formed Foil (CFF)?

Alu-Alu packaging is also known as Cold-Formed Foil due to its manufacturing process. Instead of using heat to shape the material, a specialized machine uses high mechanical pressure to stamp the multi-layered aluminum laminate into a mold at room temperature. The process does not use any heat to “form” the foil, resulting in the term “cold-formed.”

Recommend Readings:

6 Common Blister Packaging Types in the Pharmaceutical Industry