Do you know how protein powders and other chemical powders are mixed so evenly? That’s the magic of a ribbon blender machine. It’s a powerful industrial tool designed to mix large batches of dry or slightly wet materials quickly and uniformly.

Whether you’re in the food, pharma, or chemical industry, this machine plays a quiet yet crucial role behind the scenes.

In today’s article, we’ll explore what ribbon blender machines are, how they work, and what makes them different. So, if you’re in production or thinking of scaling your own product, this is a tool worth knowing.

What Is Ribbon Blender?

A ribbon blender machine is a type of industrial mixing equipment used to blend dry powders, granules, and sometimes liquids. It uses a horizontal U-shaped chamber with rotating ribbons that move materials in opposite directions to achieve a consistent and even mix.

This machine is designed to handle bulk materials quickly and efficiently. It’s ideal for mixing spices, flour, animal feed, protein powders, cosmetics, and more. As for the usage, you’ll see them being incorporated in the food, pharmaceutical, and agricultural industries.

In short, ribbon blenders are the go-to choice for businesses that need uniform, high-quality blends every time.

How Does the Ribbon blender Machine Work?

Here’s how the ribbon blender machine works:

Step 1: The dry powder and granules are loaded into a horizontal, U-shaped mixing tank.

Step 2: The operator then uses the control panel to turn on the metal ribbons inside the tank. He/she can also change the speed of the ribbons from this panel, as well as other parameters.

Step 3: The two ribbon blades begin to spin in opposite directions to mix the powders evenly. The outer ribbon moves the material toward the center, while the inner ribbon moves it outward.

Step 4: Once the raw materials are properly mixed, the material is released from a valve at the bottom of the tank. It gets collected in a big tub.

What’s the average mixing time of a ribbon blender machine?

The process typically takes between 3 and 5 minutes. This makes these machines highly efficient and optimized for quick mixing. However, it depends on the type and amount of the material.

Different Types of Ribbon Blender

Ribbon blenders are available in various designs to suit different mixing needs. Each type has a slightly different structure and purpose, but they all follow the same basic principle of ribbon mixing. Here are the three most common types:

1. Single Ribbon blender

Best for: Simple dry blending jobs.

A single ribbon blender typically features a single spiral ribbon, usually wound in one direction. It pushes materials in a single flow, typically from one end of the tank to the other.

This design is optimal for lighter or free-flowing powders that don’t require intense mixing. The only drawback of this machine is that it’s not ideal for tough and sticky mixtures.

2. Double Ribbon blender

Best for: Powders, granules, and even semi-wet materials.

The double ribbon blender is the most commonly used type in industries today. It has two spiral ribbons, one inner and one outer, that move materials in opposite directions.

This counter-flow motion helps achieve a faster and more uniform mix. However, it’s not suitable for materials that are extremely sticky or require vacuum mixing.

3. Vacuum Ribbon blender

Best for: Pharmaceutical, food, or fine chemical applications.

A vacuum ribbon blender adds another feature: the ability to create a vacuum inside the mixing chamber. This removes air and moisture from the mixture.

It is especially useful for sensitive materials or where product quality depends on a controlled atmosphere. The only problem you might face with this is that it’s a bit more complex and expensive than others.

Key Components of a Ribbon Blender Machine

If you want to understand how a ribbon blender works fully, you need to know what each part does. Every component plays an important role in the overall mixing process. These components include:

1. Mixing Chamber

The mixing chamber is the large, U-shaped body of the machine where all the ingredients are placed. It’s usually made from stainless steel or carbon steel to handle both food-grade and industrial materials.

As for the design, the mixing chamber is curved in shape to let the ribbon blades inside to move materials freely and efficiently. This helps avoid dead spots and supports an even blend of all ingredients.

In fact, over 64% of newly launched ribbon blenders for the food and pharmaceutical industries also feature a CIP (Clean-in-Place) system.

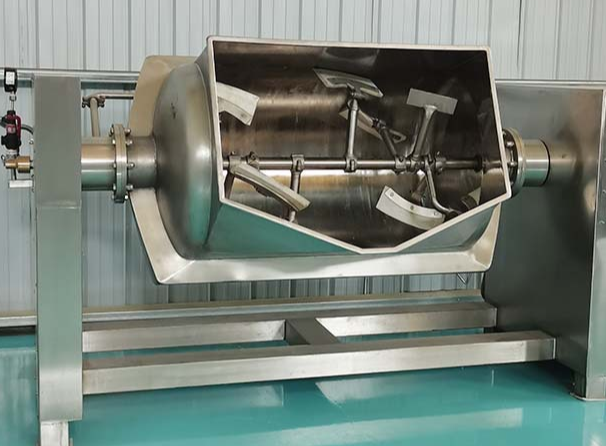

2. Agitator (Ribbon Blade)

Inside the chamber, the agitator is the part that actually does the mixing. It consists of two helical ribbons, one outer and one inner. Both are attached to a rotating shaft.

As the blade turns, the outer ribbon pushes materials toward the end of the chamber while the inner ribbon pushes them back toward the center. This creates a continuous loop, ensuring that every part of the mixture gets evenly blended.

3. Motor and Drive System

The motor is what powers the whole mixing process. It’s connected to a gearbox and the main shaft that turns the ribbon blades. This system enables the blender to run at a consistent speed, which is important for achieving uniform mixing results.

However, the best part is that you can change the motor depending on how much power you need to handle light or heavy materials.

4. Discharge Value

Once mixing is complete, the finished material needs to be removed from the chamber. That’s where the discharge value comes in. It is located at the bottom of the chamber, and this valve opens to let the mixed product out.

Some machines also use manual valves, while others are automatic. A smooth and quick discharge system saves time and helps reduce material waste between batches.

5. Cover & Safety Guards

The top of the mixing chamber is often sealed with a cover that may include ports for adding liquids or powders during operations. Many ribbon blenders also include safety guards to protect workers from moving parts.

These features improve operator safety and help maintain hygiene by keeping dust out of the mix.

Where Is a Ribbon blender Machine Used?

As mentioned before, ribbon blender machines are utilized across a wide range of industries. Specifically when thorough blending of dry powders, granules, or paste-like materials is required.

Here’s how different sectors benefit from them:

- Food Industry: Ribbon blenders blend ingredients like flour, spices, baking powder, and protein mixes. They help ensure a uniform distribution of taste, restore balance, and maintain color.

- Pharmaceutical Industry: In pharmaceutical production, these blenders are employed to combine powders for tablets, capsules, and medicinal powders. The gentle yet thorough mixing action ensures consistency and accuracy in dosage.

- Chemical Industry: These blenders handle dry chemicals, detergents, fertilizers, pigments, and plastic compounds. Due to their design, the mixture remains safe and dust-free during the blending of reactive substances.

- Agriculture Industry: To prepare feed blends, fertilizers, and seed coatings, companies bring ribbon blenders into play. They make sure that nutrients and treatments are distributed evenly, which directly supports crop health and livestock nutrition.

Ribbon Blender vs Paddle Blender: What’s the Difference?

Even though ribbon blender and paddle blender might seem familiar at first glance, here’s a comparison between the two:

Feature | Ribbon blender | Paddle blender |

Mixing Mechanism | Inner and outer helical ribbons move material in opposite directions | Flat paddles scoop and fold materials |

Mixing Stages | Typically single-stage mixing | Can accommodate staged mixing with greater control |

Design Shape | U-shaped horizontal trough | U- or W-shaped horizontal trough |

Discharge Method | Bottom center discharge (quick release) | Side or bottom discharge; more flexible design |

Capacity Range | Large capacities; scalable for industrial use | Small to medium capacities; often customizable |

Mixing Time | Faster mixing (typically 5–15 minutes) | Slightly longer mixing time due to gentle motion |

Applications | Spices, protein powders, chemicals, animal feed | Baby food, pharmaceuticals, wet pastes, delicate ingredients |

Flow Pattern | Radial and axial (two-way counter flow) | Tumbling and folding action |

Ribbon blender vs Vertical blender: Which One Fits Your Factory?

Let’s understand the difference between a ribbon blender and a vertical blender with a table:

Feature | Ribbon blender | Vertical blender |

Orientation | Horizontal | Vertical |

Mixing Mechanism | Spiral ribbons move materials in opposite directions | Vertical screw lifts and tumbles materials from bottom to top |

Batch Size | Handles large batches with ease | More suitable for smaller to medium batches |

Mixing Time | Faster mixing cycles | Slower due to upward flow mechanism |

Footprint / Space | Requires more floor space | Compact; occupies less floor space |

Loading/Unloading | Easy due to horizontal orientation | May require additional effort or equipment |

Applications | Chemicals, protein powder, spices, dry food blends | Animal feed, agricultural blends, light fibrous materials |

Ease of Cleaning | Easier access due to horizontal design | Can be harder to clean due to vertical depth |

Cost | Generally more expensive due to size | More budget-friendly for small-scale operations |

Takeaway

Ribbon blender machines get the job done more efficiently. Their simple design and ability to handle large batches make them a smart investment for many manufacturing setups.

So, if your production involves consistent mixing of dry or semi-wet materials, a ribbon blender could be exactly what your process needs. As demand for mixed products continues to grow, having the right equipment can set you up for real success.

FAQs

1. Can a ribbon blender handle liquids or only dry materials?

Ribbon blenders are primarily designed for dry powders and granular materials, but they can also handle semi-wet or liquid additives. However, they are not ideal for fully wet or slurry-based mixtures. For that, a different type of blender would be more suitable.

2. Can ribbon blenders be used for food-grade products?

Yes, you can absolutely use ribbon blenders for food-grade products. Many of the models are made from stainless steel contact parts and are designed to meet food safety standards. These machines are commonly used in the production of protein powders, flour blends, spices, baking mixes, and other similar products.

3. How much power does a ribbon blender consume?

Small lab-scale units may use around 2-5 kW, while larger industrial models can require 15-30 kW or more. However, ribbon blenders are known for being energy efficient compared to other high-intensity mixing equipment.