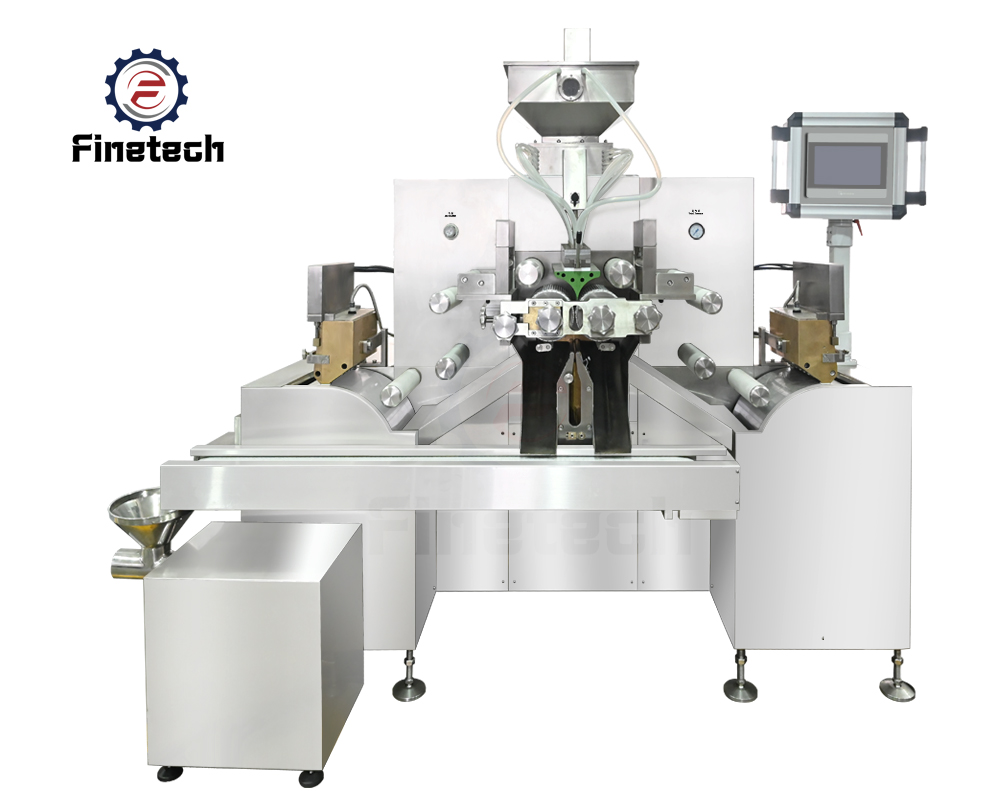

300 Soft Gel Capsule Making Machine

Designed for pharmaceutical, healthcare product, cosmetics manufacturers, and high-grade food processing industries. The core advantages such as high-speed molding, precise metering, and stable operation. The equipment has a dual-pump quantitative filling system which can accurately control the filling amount of the content (±1% error rate), Applied for producing soft capsules of liquid, semi-solid, oily and high-viscosity materials. Equipped with a fully automatic rotary molding system, it can achieve efficient and continuous production (capacity can reach 30,000 softgel capsules per hour). The entire machine complies with GMP/FDA standards, and key components are made of medical-grade stainless steel and food contact safety materials to ensure the hygiene and safety of the production process.

Need a Custom Quote?

Or More information About this product? Contact our sales stuff today!

Key Features

Technical Data

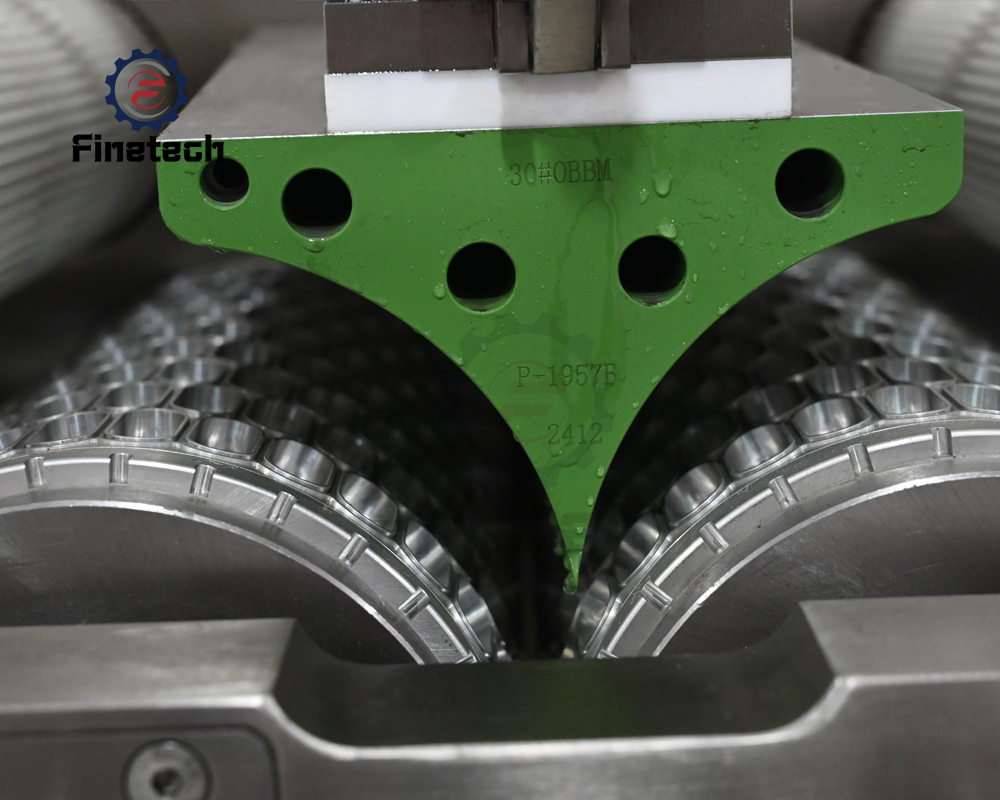

1. Its double-pump quantitative filling technology means that its filling accuracy reaches ±1%, ensuring the consistent weight of capsule contents (especially suitable for high-value materials such as fish oil and probiotics). The precision molding system ensures uniform capsule wall thickness (±0.05mm), a smooth and flawless appearance, and improved product grade.

2. Single machine production capacity can reach 30,000 capsules per hour (specific parameters are adjustable), which meets the needs of large-scale production and reduces unit costs. The full touchscreen operation interface supports one-button start/stop, reduces manual intervention, and improves production efficiency.

3. The key components are made of medical-grade 316L stainless steel and FDA-certified food contact materials, which meet the highest hygiene standards in the pharmaceutical and food industries. Its standardized mold interface and 5-minute specification switching (such as capsules size No. 000 to No. 5) makes it adaptable to small-batch production of multiple products.

| Model: | FTRJ-300 |

| Capacity: | Oval 4#: Around 221760 pes per hour at 4rpm. Oval 8#: Around 119040 pcs per hour at 4rpm. Oval 20#: Around 80640 pcs per hour at 4rpm. Oblong 4#.Around 164640 pcs per hour at 4rpm. Oblong 8#:Around 134400 pcs per hour at 4rpm. Oblong 20#:Around 69120 pcs per hour at 4rpm. Round 8#: Around 117600 pcs per hour at 4rpm. |

| Roller die rated speed: | 0~5r/min |

| Pillar Quantity: | 24 PCS |

| Roller die size: | 150x300mm |

| Single piston feeding volume: | 0.75~2ml |

| Power supply: | 380V 50Hz |

| Total power: | 11.5kw |

| Noise: | <75dBA |

| Dimension: | 2200X1275X1900mm |

| Net weight: | 2189kg |