Counting pills by hand takes time, and that’s actually a universally known fact.

That’s why more pharmacies, clinics, and supplement manufacturers are now switching to automated pill counter machines. These devices speed up the workflows, reduce counting errors, and help businesses calculate their true cost per tablet.

So, if you’re wondering how much a pill counter machine costs, we can help with that. Let’s see exactly how much these machines cost and how to estimate the cost per tablet.

Key Takeaways

The typical costs of different types of tablet counting machines are:

| Machine Type | Best For | Average Price Range |

| Manual / Handheld Pill Counters | Small clinics, pharmacies with low volume | $200-$1,000 |

| Semi-Automatic Tablet Counters | Medium-volume pharmacies and supplement businesses | $1,000-$7,000 |

| Fully Automatic Counting & Bottling Lines | High-volume production and pharma manufacturing | $7,000-$50,000+ |

What Is a Pill Counter Machine?

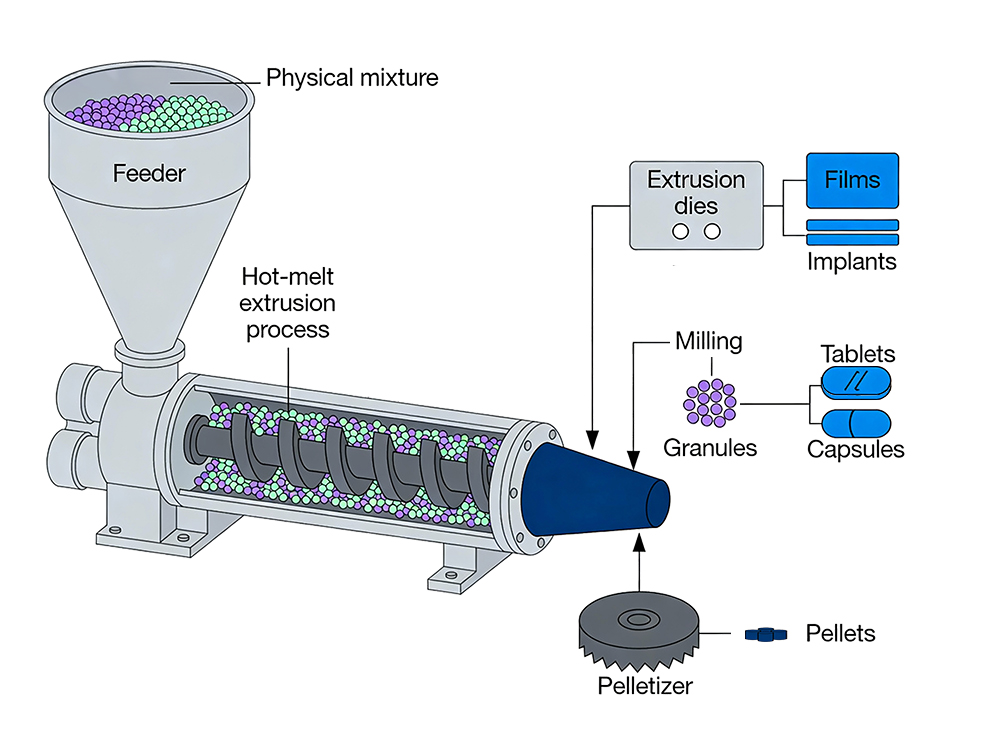

A pill counter machine is a device used in pharmacies and supplement manufacturing to quickly and accurately count pills, tablets, or capsules. Instead of counting by hand, the machine automatically scans, sorts, and counts each unit.

Manual pill counting may seem simple, but it’s slow and risky. In fact, studies show that manual pill counting results in approximately 1.6% (4 in 250) dispensing errors.

When scaled to batches containing thousands of tablets, that error rate can translate to hundreds of miscounted doses, putting both accuracy and patient safety at risk. That’s why a pill counter machine is a necessity in pharmaceutical facilities.

How Much Does a Pill Counter Machine Cost?

Pill counter machines vary in price depending on the technology, speed, and capacity. The cost generally falls into three main categories:

1. Manual / Handheld Pill Counters (Budget Option)

These machines are compact, low-cost devices used mainly in small pharmacies or clinics. They reduce basic counting errors, but still require human effort.

If you’re considering upgrading from fully manual counting but don’t need automation, this option is ideal. They are slightly faster than manual counting and are best suited for low daily prescription volumes.

Average Price: $200 to $1,000.

2. Semi-Automatic Pill Counters (Most Popular)

Semi-automatic machines use infrared sensors or an optical camera to count different types of pills as they pass through the chute. They are way faster and more accurate than manual counters.

Such machines are popular in retail pharmacies and supplements, as they’re capable of counting thousands of pills per hour. Many pharmacies opt for this tier because it strikes the best balance between cost and automation.

Average Price: $1,000 to $7,000.

3. Fully Automatic Counting / Bottling Systems (High Volume)

If you’re willing to make a significant investment to reduce labor costs and increase output, then fully automatic ones are your best bet.

These are mostly used in pharmaceutical production lines, where both counting and bottle filling are fully automated. They are extremely fast and designed for continuous production, which requires zero manual handling.

Average Price: $7,000 to $50,000+

Cost Per Tablet: How to Calculate ROI (With Example)

For pharmaceutical and nutraceutical manufacturers, the conversation is not about “saving time at the counter.” It’s about production efficiency, throughput, and cost per tablet when manufactured at scale.

That’s why manufacturers use the Cost Per Tablet (CPT) calculation. It helps evaluate whether a pill counter machine increases output and reduces operational costs over the machine’s lifespan.

Here’s the simple formula manufacturers use:

Cost Per Tablet = Equipment Cost / Total Tablets Counted Over Machine Lifetime

Example

Assume your facility purchases an automatic counting machine for $18,000.

Your production output averages:

- 30,000 tablets per hour.

- 8 hours per shift.

- 240 production days per year.

Annual output:

30,000 × 8 × 240 = 57,600,000 tablets per year

Now, calculate the cost per tablet:

$18,000 / 57,600,000 = $0.00031 per tablet

That’s less than one-tenth of a cent per tablet counted and processed.

What This Means for Manufacturers

Here’s what this means for manufacturers:

- Machine cost becomes negligible when spread across millions of tablets.

- Automation reduces bottlenecks on the production line.

- The faster and more accurate the machine, the lower the CPT and the higher your margin.

For manufacturers, an automated pill counter isn’t just a device; it’s a profit multiplier. It increases output per labor hour while reducing the risk of miscounts, rework, and compliance issues.

Moreover, even if equipment costs were to double, the cost per tablet would remain extremely low at high volumes.

Factors That Influence Pill Counter Machine Pricing

The price of a pill counting machine varies because not all machines are built for the same workload. A machine designed for retail pharmacies may only count a few thousand capsules or tablets per day, while manufacturers need a counter that can handle millions of tablets per month.

Here are the primary factors that determine machine pricing:

1. Counting Technology (Optical vs. Sensor-based)

Machines designed for high-volume production utilize multi-channel optical or photoelectric sensors to detect every pill that passes through, even at high speeds.

Entry-level machines usually have a single sensor and slower throughput. Meanwhile, manufacturing-grade machines include optical vision and multi-channel sensors for higher accuracy.

Even though it’s not directly related to the purchase cost, the high accuracy eliminates costly rework, thus saving money over time.

2. Production Throughput (Tablets per minute/hour)

Often, manufacturers care more about the output per hour, rather than the cost of the machine. Simply put, higher speed means higher price.

| Machine Type | Speed Capacity | Pricing Impact |

| Entry-level / Small clinic | 500–3,000 pills/hr | Lowest price |

| Mid-range / Semi-auto | 5,000–30,000 pills/hr | Moderate price |

| Fully automatic / Industrial | 50,000+/hr & bottling | Highest price |

3. Integration With Filling or Bottling Lines

Manufacturers typically require:

- Conveyor integration.

- Bottle filling automation.

- Batch counting + continuous feed.

The more integration required, the higher the machine cost. But the good news is that the Cost Per Tablet decreases when production runs continuously.

4. Accuracy Sensors + Dust Management

If there’s dust on the tablets, it can block basic sensors and cause miscounts. To prevent that from happening, machines include:

- Dust shields.

- Air filtration systems.

- Auto-sensor calibration.

When there’s less dust, there will be fewer cleaning stops and, eventually, a lower miscount risk.

5. Software, Memory, and Smart Functions

Higher-end machines come with touchscreen HMIs, batch memory storage, auto-calibration, and self-diagnostic features.

These extra features come at a higher cost. However, manufacturers don’t think like that. They go for the benefits over the cost. The benefits include saving operator time, reducing manual handling, and increasing output per shift.

Automated Pill Counter Machine vs. Manual Counting

Manual counting requires labor, slows packaging lines, and increases the risk of miscounts. All these bottlenecks are eliminated by automated pill counter machines. Here’s a quick, yet detailed comparison between the two:

| Feature | Manual Counting | Automated Pill Counter |

| Accuracy | Error rate up to 1% | Near 100% accuracy at high speed |

| Labor Cost | Multiple operators required | One operator for full-time |

| Throughput | Slow and inconsistent | Up to 50,000+ tablets/hr |

| Cost Per Tablet | Increase with volume | Decreases with volume |

| Compliance | Higher chance of miscounts | Consistent and trackable results |

Time to Upgrade to Automated Counting

When it comes to counting tablets at scale, the real cost is downtime, miscounts, rework, and wasted labor hours. A cheaper machine might save money upfront, but if it slows down production, it ends up costing far more over time.

Remember one thing: Reliable pill-counting machines pay for themselves; cheap ones never do. That’s precisely what we offer at Finetech.

Whether you need a semi-automatic counter or a fully automated counting and bottling line, our team matches you with the exact machine.

Click here to get an instant quote on our pill counting machines!

References

TOP 10 Tablet Counting Machine Manufacturers.

Tablet Counting Machine: Features, Types, Working Principle, and Purpose.