When you’re thinking of scaling capsule production, the machine you choose can make or break your workflow. Whether it’s a 100-, 200-, 300-, or 400-Hole capsule filling machine, each one comes with its own strengths.

But the real question is, which one best fits your business?

If you’ve ever felt torn between speed, cost, and efficiency, you’re not alone. Many manufacturers face the same challenge, and picking the wrong size often means wasted time and resources.

That’s why we’re breaking it down for you, so you’ll know exactly which option makes sense for your production goals.

What Does “Hole Count” Mean for Manufacturers?

A capsule filling machine with 100, 200, 300, or 400 holes simply refers to the number of capsules the tray can hold and fill at once. Each hole is like a slot where one capsule body sits while you add the powder.

It matters because the hole count directly affects batch size and production speed.

For instance, a 100-hole filling machine means you’re filling 100 capsules per run. So, if your daily target is 5,000 capsules, you’ll have to repeat the process 50 times. At the same time, a 400-hole machine that handles 400 capsules simultaneously can complete the same task in 12 runs.

The difference in efficiency is substantial, especially when considering labor costs, operator fatigue, and consistency.

Different Hole Counts for Capsule Filling Machines

Hole count is the single most visible specification on a capsule filler because it directly ties to the number of capsules that can be made in one cycle. Here are the most common machines, along with their approximate hourly outputs.

1. 100-Hole Capsule Filling Machine

The 100-hole machine is the smallest standard option. It holds 100 capsules per cycle, making it ideal for small batch runs, startups, or R&D labs where a high output is not necessary. On average, you can expect around 1,800-2,500 capsules per hour. However, it also depends on the operator and powder flow.

If you only need a few thousand capsules per day, this is a cost-effective and easy-to-operate solution. The only trade-off is speed.

2. 200-Hole Capsule Filling Machine

A step-up in efficiency is the 200-hole version, which doubles the capacity compared to the 100-hole. Each run fills 200 capsules, giving you 4,250 to 4,500 capsules per hour.

This machine is often the “entry point” for supplement brands moving beyond hobby-level production. It’s still manual, but it provides a faster turnaround, fewer cycles to meet targets, and less operator fatigue.

3. 300-Hole Capsule Filling Machine

With 300 slots per tray, this model produces 6,000 to 8,000 capsules per hour. It’s designed for growing manufacturers who need higher volume but aren’t ready to commit to full automation. If you’re scaling up, this machine is the ideal choice with a higher ROI.

At this scale, you can comfortably hit 50,000 capsules in one shift with only a couple of machines. The 300-hole unit reduces cycle repetition, improves consistency, and supports faster turnaround.

4. 400-Hole Capsule Filling Machine

The 400-hole machine is the largest in the manual/semi-auto category. Depending on the setup, it can deliver 4,000 to 5,000 capsules per hour manually or 20,000 to 24,000+ capsules per hour when automation features, such as powder loaders, are utilized.

This model is the workhorse for mid-sized supplement companies. It keeps labor low, reduces cycle time dramatically, and positions you closer to industrial-level output without the upfront costs of a rotary automatic machine.

Capsule Filling Machine Comparison at a Glance

Choosing between a 100, 200, 300, or 400-hole machine often comes down to output, efficiency, and the scale of your production. To make the differences clearer, here’s a side-by-side comparison.

| Hole Count | Approx. Output per Hour | Best Suited For |

| 100-Hole Machine | ~1800 to 2,500 capsules | Small labs, R&D, startups, low-volume batches |

| 200-Hole Machine | ~4250 to 4,500 capsules | Small supplement brands, early-stage manufacturers |

| 300-Hole Machine | ~6,000 to 8,000 capsules | Growing manufacturers, mid-volume daily production |

| 400-Hole Machine | ~20,000 to 40,000 capsules | Mid-sized companies, scaling operations, and higher efficiency needs |

Why Capsule Filling Output Numbers Vary

You may have noticed that the output of capsule filling per hour varies from one location to another. Some manufacturers claim higher numbers, while others report lower. That’s because many factors influence the real throughput of a machine.

Let’s break them down.

1. Capsule Size and Filling Plate

Not all capsules are the same. A size 00 capsule is bigger and holds more powder than a size 1 capsule. That means, filling larger capsule sizes takes more time per piece, which lowers the total hourly output.

The type of filling plate used also makes a difference in how smoothly the capsules fit inside the molds and fill.

2. Powder Flow and Formulation

The nature of your powder changes everything. A free-flowing herbal powder moves quickly and fills evenly.

However, sticky, hygroscopic, or very fine powders require tamping, which slows down the process and increases the likelihood of rejects or rework. This is why two manufacturers using the same machine may report very different capacities.

3. Operator Skill and Technique

Manual machines are limited by people, not just mechanics. A skilled operator works faster, keeps the process consistent, and produces fewer rejects.

That’s why manufacturer specifications often say “depending on formulation and operator skill.” Simply put, more experience equals better throughput.

4. Machine Type: Manual vs Semi-Auto vs Automatic

The type of machine sets the baseline for output. Manual systems depend entirely on the operator, while semi-automatic systems use tools such as powder loaders and tampers to increase speed.

Similarly, fully automatic capsule filling machines take it a step further with vacuum pickers and conveyors, which automate each of the steps. Industry studies also confirm that automation consistently boosts productivity while reducing human error.

5. Downtime, Cleaning, and Changeovers

With unplanned downtime costing around $260,000 per hour, it’s essential to keep your machines in optimal condition. The only way to do so is through regular maintenance, cleaning, and capsule size changeovers.

If these steps take too long, your effective hourly output across a shift will drop. Planning for downtime is crucial when calculating true capacity.

| Remember: Output numbers aren’t fixed. They depend on how you run the machine, what you’re filling, and who’s operating it |

Choose the Right Hole Count for Your Business

Ultimately, the hole count is a direct reflection of your production speed and performance. A 100-hole filler might be perfect for R&D or small-batch work, while 300- or 400-hole machines can transform how quickly you scale up daily output.

If you’re exploring options and need expert guidance, Finetech can provide you with assistance. We offer a diverse range of capsule-filling machines, ensuring you can always find the ideal one for your business.

Contact Finetech today to get a quick quote for any of our machines!

FAQs

1. What types of capsule filling machines are there?

Capsule filling machines generally fall into three categories: manual, semi-automatic, and fully automatic. Manual models are low-cost and suit small runs. Semi-automatic machines speed up output but still need operator input. Fully automatic systems handle every step with minimal labor.

2. Can capsule filling machines handle powders, pellets, and liquids?

Most capsule fillers are designed for powder formulations, but many models also allow filling of granules, pellets, and beads. For liquids, you’ll need specialized attachments or machines designed specifically for liquid dosing. Always confirm material compatibility with the supplier before investing.

3. How accurate are capsule filling machines with weight?

Capsule filling accuracy depends on machine design and formulation. Powder filling machines typically achieve a weight variation of ±3-5 % if calibrated correctly. Liquid and pellet dosing systems can be even more precise. However, it all comes down to operator skill and powder flow properties.

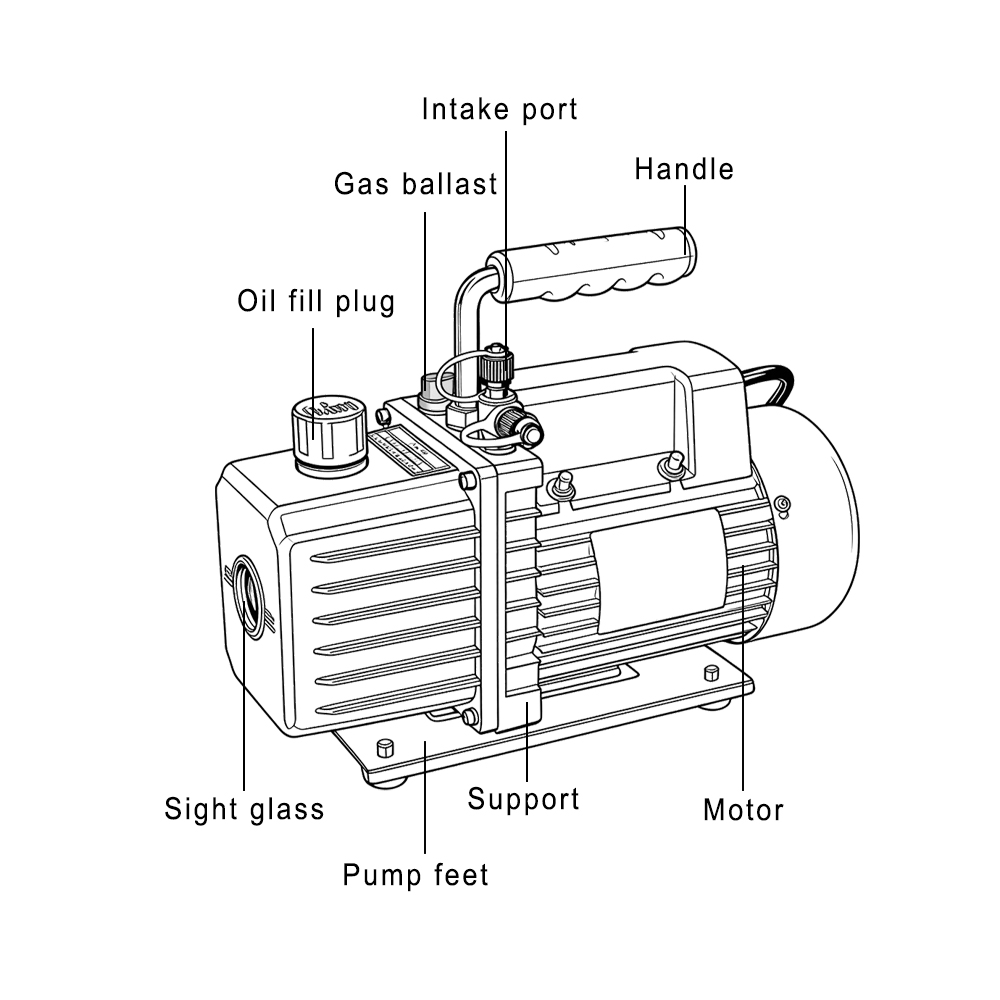

4. May I know the manual capsule filler parts and their names?

Please check it: