16 Station Tablet Compression Machine

A 16-station tablet compression machine is a rotary press used in the pharmaceutical, nutraceutical, chemical, and food industries to produce tablets in high volumes. The “16-station” refers to the number of tooling stations (sets of upper and lower punches and dies) mounted on the rotating turret. This allows it to produce 16 tablets per complete revolution of the turret, making it significantly more productive than single-station or lower-station machines.

Need a Custom Quote?

Or More information About this product? Contact our sales stuff today!

Key Features

Technical Data

Machine Details

FAQ

Application

Single roller,fully enclosed in compliance with GMP.

PLC and touch screen,friendly and easy to operate.

The machine can stop automatically in case of overpressure.

Force feederis optional.

| Model | ZPY-8 | ZPY-10 | ZPY-16 | |

| No.of Stations 8 10 | 16 | |||

| Tooling Standard | D | D | B | |

| Max Production Capacity(pcs/h) | 14400- 18000 | 28800 | ||

| Max Turret Speed(r/min) | 0-30 | |||

| Max Pressure(kn) 80 | ||||

| Max Filling Depth(mm) | 20 | |||

| Max Tablet Thickness(mm) | 0.5~8 | |||

| Msx TabletDiameter(mm) | φ25 | φ25 | φ18 | |

| MotorPower(kw) 2.2KW/380V,50Hz | ||||

| Overall Size(mm) | 540*520*1600 | |||

| Machine Weight(kg) 850 | ||||

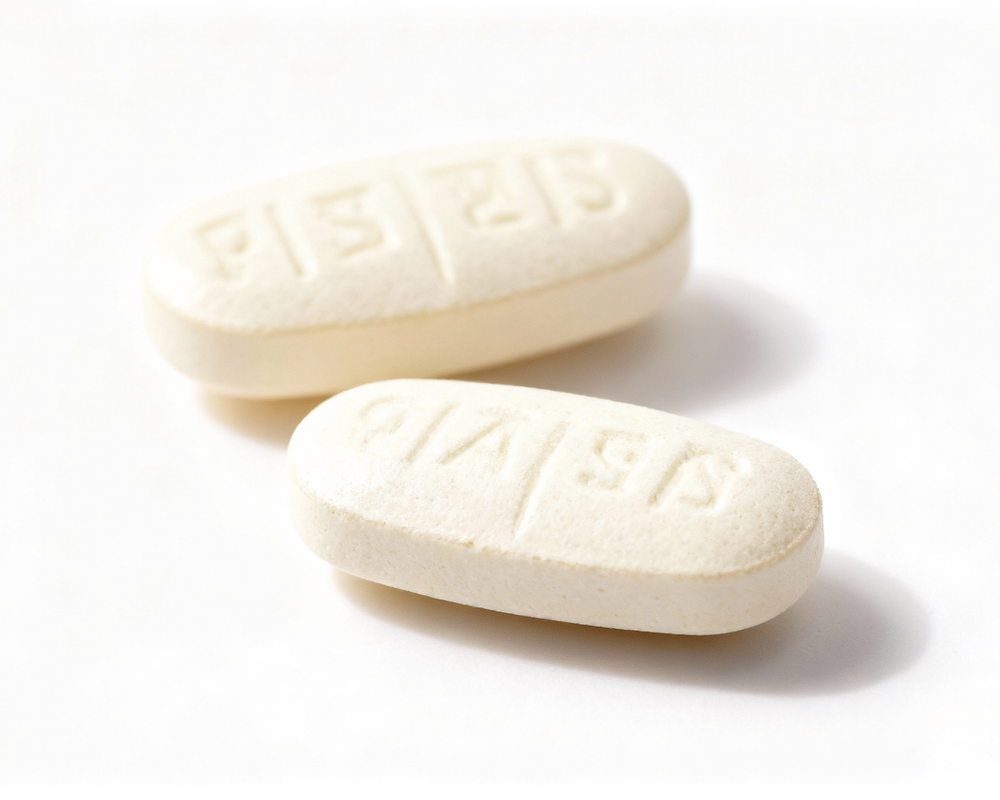

It is a rotary tablet press with 16 sets of upper and lower punches and dies arranged around a circular turret. It compresses powder or granules into tablets of uniform size, weight, and hardness at high production speeds.

Output depends on tooling size (e.g., B, D, BB), tablet size, and RPM. A typical range is 80,000 to 180,000 tablets per hour. Always refer to the machine's specific specification sheet.

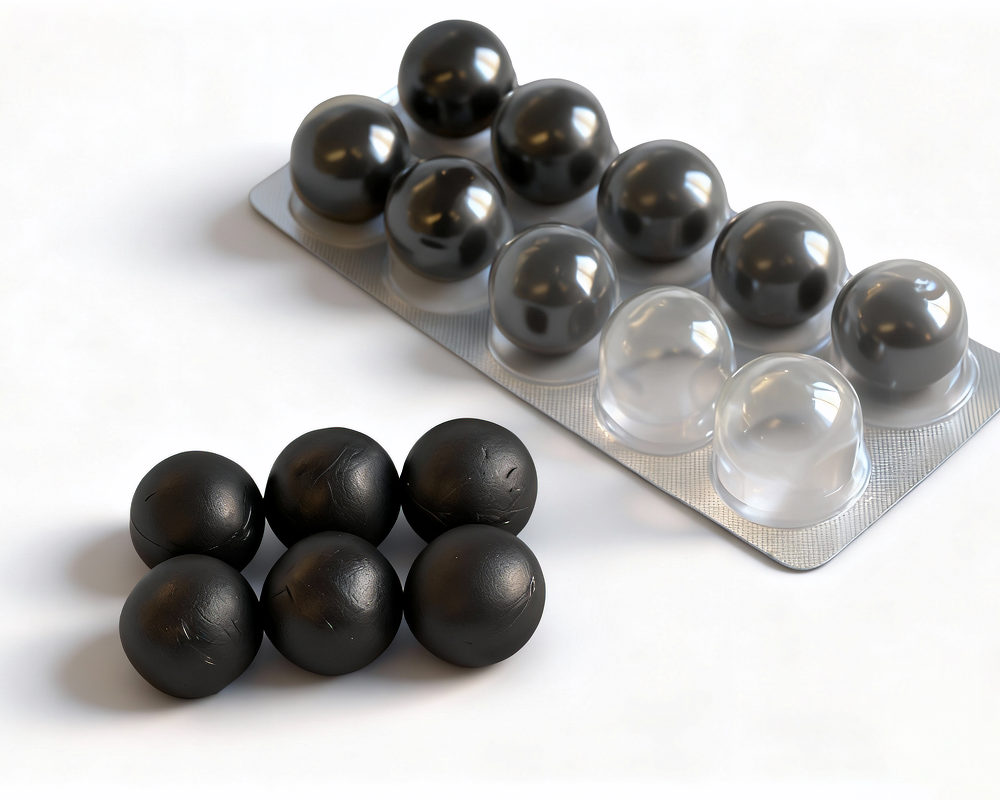

It can compress a wide range of pharmaceutical powders, granulations, nutraceuticals, herbal extracts, cosmetics, and industrial products like ceramics or catalysts. Material must have good flow and compaction properties.

Turret: Rotating head holding punches and dies.

Feeder: (e.g., force feeder) that distributes powder into dies.

Cams: Control the movement of upper and lower punches for filling, compression, and ejection.

Compression Rollers: Apply the main compression force.

Pre-compression Roller: Optional, for de-aerating the powder before main compression.

Control Panel (HMI): For setting and monitoring parameters like pressure, speed, and weight.

Most 16-station presses use "B," "D," or "BB" type tooling per TSM (Tablet Specification Manual) or EU standards. It's crucial to use the correct standard and quality tooling specified for your machine model.

No. Operators must be thoroughly trained on operation, cleaning, safety interlocks, and lock-out/tag-out (LOTO) procedures to prevent serious injury or machine damage.

16-Station: Ideal for mid-volume production, R&D, pilot plants, and products with smaller batch sizes. Offers a great balance of flexibility, speed, and lower capital cost.