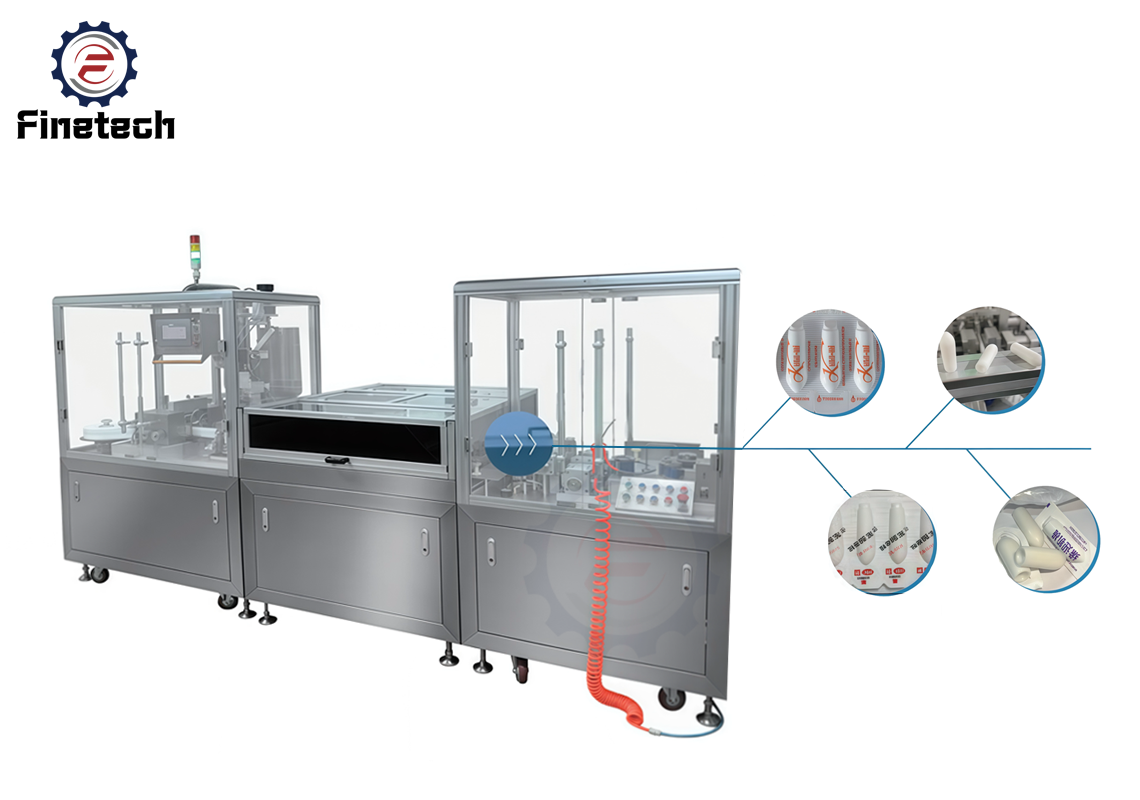

SJ-1L Suppository Filling and Sealing Machine

The SJ-1L Suppository Filling and Sealing Machine is highly efficient, fully automatic equipment designed for small to medium batch production. It has a compact structure, occupying minimal floor space. Applied for R&D institutions, clinical trials, or low to medium-scale suppository production needs. Its core functions include precise mixing, accurate filling, and smooth demolding.

Need a Custom Quote?

Or More information About this product? Contact our sales stuff today!

Key Features

Technical Data

Machine Details

FAQ

Application Suppository Types

The SJ-1L suppository filling and sealing machine is applied for the production of specially shaped suppositories such as bullet-shaped, torpedo-shaped and duckbill-shaped.

The equipment has programmable PLC controls and a simple human-machine interface which is easy to operate and offers precise temperature control and stable operation.

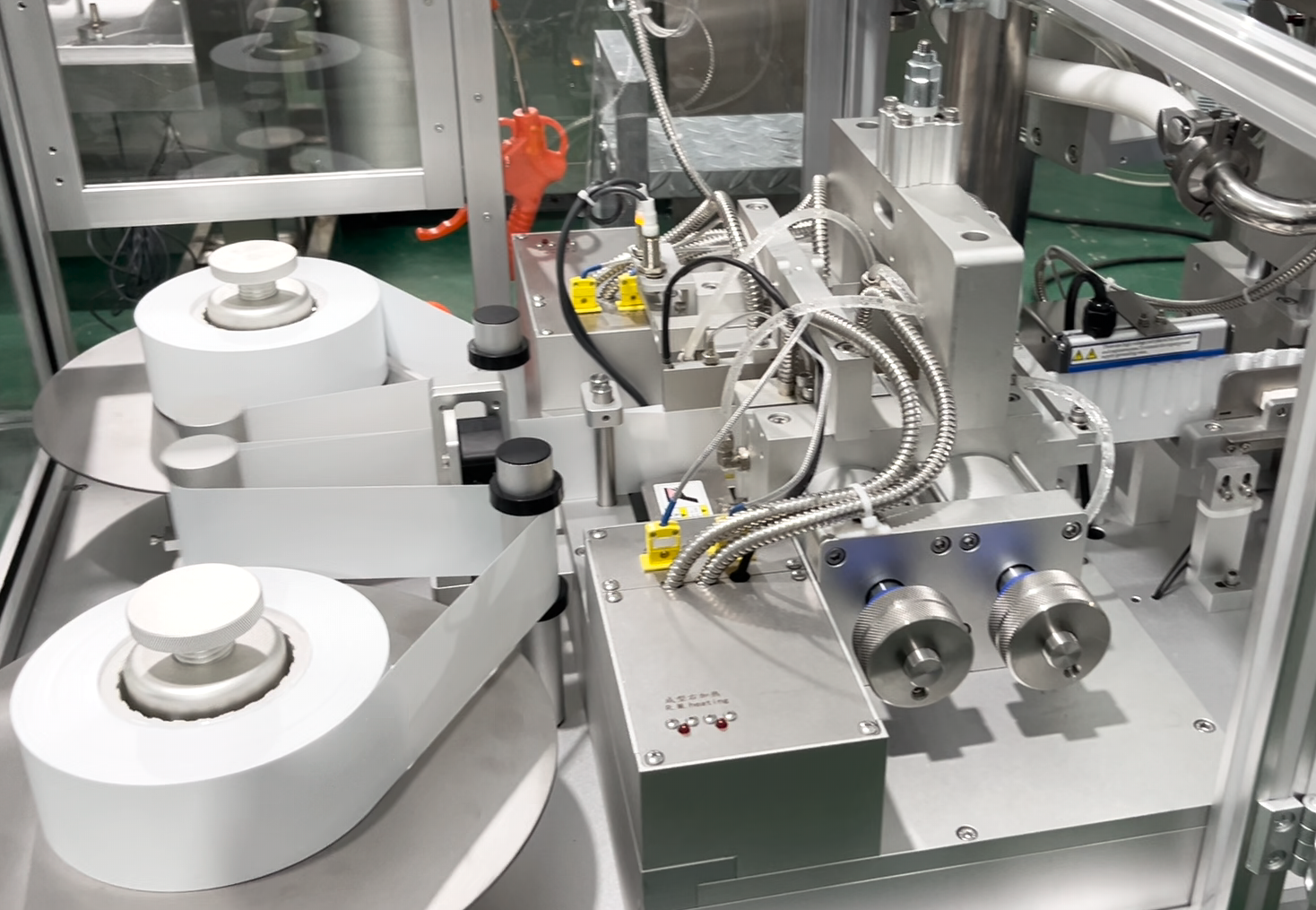

The mold temperature sensor and high-precision microcomputer control system maintain a constant temperature.

The liquid storage tank is made of 316L stainless steel, with appropriate volume, insulation, heating functions and precise temperature control. The storage tank is equipped with a stirring device to keep the uniformity of the liquid medicine in the barrel at all times; the liquid storage tank is connected to the filling mechanism through a pipeline, and the liquid medicine is insulated and circulated to ensure its fluidity to meet filling requirement.

The insertion-type linear perfusion mechanism features accurate positioning, no dripping of medicine, and no wall hanging; the single-grain measurement ranges from 0.5 to 5ml, and the filling error is ±2%.

| Model | SJ-1L |

| Output/hour | 1,000-2,000 grains/hour |

| Dosage deviation | <±2% |

| Capacity of the bucket | 20L |

| Gas consumption/per minute | 0.6m³ |

| Working voltage | Three-phase Ac 380V |

| Suitable suppository shape | Bullet head type, torpedo type, duck shape and various other shapes |

| External dimensions | 2300mm*900mm*1800mm(L*W*H) |

| Applicable matrix | Synthetic fatty acids glycerine, glycerol gelatin, polyethylene glycol, etc. |

| Unit Dose | 0.5-5ml |

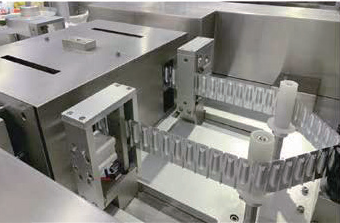

| packaging flim | PVC/PE, Thickness: 0.15 mm |

| working air pressure | ≥0.6Mpa |

| Water consumption/per hour | 50kg (recycling) |

| Total power | 2.5kw |

Modern machines can handle a wide range, including:

Fat-based (e.g., cocoa butter, Witepsol, Suppocire): Require precise temperature control to avoid polymorphic transitions.

Water-soluble/Glycerin-based (e.g., glycerin suppositories): Often more viscous and may require specialized pumps.

PEG (Polyethylene Glycol) based: Have a higher melting point and are less sensitive to temperature fluctuation.

Thermosensitive formulations containing probiotics or live cultures require very gentle, low-temperature processing.

Capacity varies widely:

Semi-automatic: 500 – 2,000 suppositories per hour.

Rotary Automatic: 2,000 – 12,000+ suppositories per hour.

Output depends on the number of mould cavities, cycle time, and suppository weight.

They are often integrated but have distinct functions:

Moulding Machine: Creates the suppository shape from molten mass using cooled metal moulds.

Blister Sealing Machine: Packages the finished suppositories into foil/plastic blisters for unit-dose, protection, and stability.

Many "filling and sealing" lines combine both in one continuous process.

Piston Pump: Most common. Excellent for accuracy (±1-2%) with most fats and PEGs. Easier to clean and maintain for standard formulations.

Peristaltic Pump: Ideal for shear-sensitive, very sticky, or highly abrasive formulations. Avoids metal contact, reducing contamination risk. Tubing is a consumable part.

There is no universal setting. It is formulation-dependent. A general rule:

Hopper: 2-5°C above the melting point of the base.

Nozzles: 1-3°C above hopper temperature to prevent solidification in the tip.

Moulds: 5-15°C below the solidification point. Always follow the base manufacturer's recommendation and conduct small-scale trials.

Via a gentle ejection mechanism:

Ejector Pins: Precision pins that push from the bottom of the mould cavity. Pin heads must be perfectly flush.

Air Ejection: A controlled puff of compressed air. Often used for very soft suppositories or in conjunction with pins.

Surface Coating: Moulds are often chrome-plated or coated with PTFE (non-stick) to facilitate release.

Cause: Incorrect temperature, pressure, or dwell time of the sealing jaws.

Solution: Calibrate sealing jaw temperature (use a surface pyrometer), increase pressure, or adjust the sealing time. Also, check lidding foil specification compatibility with the forming film.

Yes, but it requires a changeover. This involves:

Changing the mould plates to ones with different cavity shapes/volumes.

Adjusting or changing the filling nozzles.

Possibly changing the blister forming dies and trimming punches.

Re-calibrating temperatures and pump settings. Modern machines aim for quick changeover (under 30 minutes).

.png)