Manually filling and sealing bottles, whether of canned juice or mineral water, can be quite a hassle. You will end up with high labor costs and, most probably, poor quality control. That’s where bottling line equipment comes in! It ensures your products are consistent and also helps lower business expenses. Keep reading to learn more about bottling line equipment, its process and benefits.

What is a Bottling Line?

Typically, the bottling line, also known as the filling line, is a series of interconnected equipment that automates the process of filling bottles. Multiple machines are involved in this, including rinsers, fillers, cappers, and labelers.

It’s the last part of the production of bottled drinks, streamlining the production of syrups, sauces, and chemicals, among other things. That’s why their market is quickly growing and expected to hit a massive USD 6,297.4 million by 2030.

Steps Involved in a Bottling Line

Now that you are aware of the basics of bottling line equipment, let’s discuss the steps involved in this:

- The first step involves cleaning and sterilizing the bottles to remove any contaminants. For instance, the operator has to remove residues and foreign matter so the equipment stays pristine.

- Bottles are placed under the nozzle of a filling machine to fill them with liquids such as water, juice, milk, and other items. The type of filling machine used depends on the product’s viscosity and overall order load.

- After filling, they move the bottles to a capping station where lids and caps are applied for proper and secure sealing.

- The operator then uses labelers to attach labels to the bottles. Labels include information such as brand data and product details, such as manufacturing and expiry dates and ingredients.

- Throughout the process, quality checks often use sensors to ensure that bottles have the same liquid level and cap tightness.

Types of liquids used in bottling lines

1. Water (Still & Sparkling)

Key Properties: Low viscosity, neutral pH. Sparkling water has dissolved CO₂.

Critical Filling Method:

Still: Gravity or Pressure Filler (simple, high-speed).

Sparkling: Isobaric (Counter-Pressure) Filler (to retain carbonation).

2. Carbonated Soft Drinks (Soda, Tonic, Mixers)

Key Properties: High carbonation, sugar content (can be sticky), acidity.

Critical Filling Method: Isobaric (Counter-Pressure) Filler. Non-negotiable.

3. Beer & Cider

Key Properties: Carbonated, highly foam-sensitive, oxygen-sensitive, light-sensitive (for some).

Critical Filling Method: Low-Pressure Isobaric Filler. Extremely gentle to minimize “fob” (foam) which destroys head (foam) and picks up oxygen.

4. Juice & NFC (Not From Concentrate) Beverages

Key Properties: Viscous (with pulp), oxidizes quickly (Vitamin C loss, browning), can be acidic, particulate matter.

Critical Filling Method:

Cold Filling: Volumetric (Piston) Filler for accuracy with pulp. Often paired with Hot Fill process.

Hot Fill: Gravity/Pressure filler for products filled at ~185-203°F (85-95°C) to sterilize the container.

5. Dairy & Plant-Based Milks

Key Properties: Perishable, viscous, emulsion-based (can separate), sensitive to heat and shear.

Critical Filling Method: Volumetric (Piston) Filler or Positive Pressure Filler with gentle product handling.

6. Wine

Key Properties: Still or sparkling, delicate aromas, highly oxygen-sensitive.

Critical Filling Method:

Still Wine: Vacuum Filler (gentle, low-oxygen) or Gravity Filler with inert gas blanket.

Sparkling Wine (Champagne): Isobaric Filler (like beer, but for higher pressure). Transfer Dosage/Degorgement line for the traditional method.

7. Spirits & Liquors

Key Properties: High alcohol content (solvent), high-value (taxation), often viscous (liqueurs).

Critical Filling Method: Net Weight Filler. This is the legal and commercial standard for high-value spirits due to its absolute accuracy (filling by mass, not volume).

8. Edible Oils & Vinegars

Key Properties: Oily (can foam), can oxidize, viscous.

Critical Filling Method: Gravity or Volumetric Filler designed for oily products (special seals, drip-less nozzles).

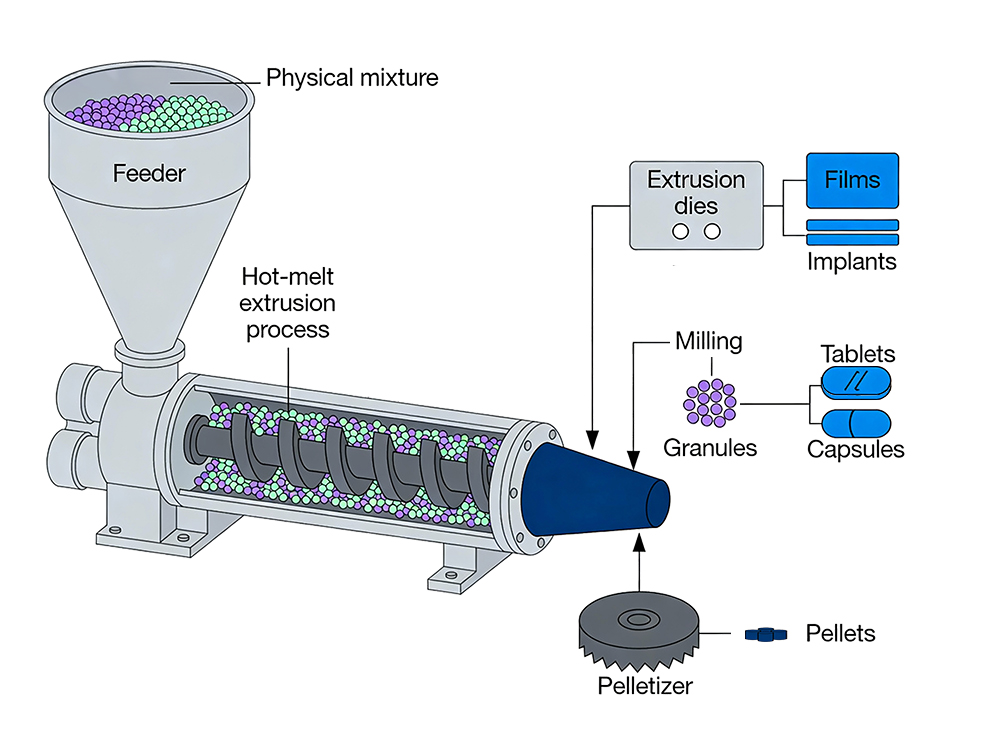

9. Pharmaceuticals & Nutraceuticals (Syrups, Tonics)

Key Properties: Sterility is paramount, often viscous, high-value.

Critical Filling Method: Peristaltic Pump Filler or Piston Filler in a Isolator. Chosen because the product only contacts sterile, disposable tubing.

10. Household & Industrial Liquids (Detergents, Chemicals)

Key Properties: Can be corrosive, foamy, viscous, or hazardous.

Critical Filling Method: Piston Filler or Overflow Filler (for consistent fill level of foamy products).

Summary Rule: The liquid’s physics (carbonation, viscosity) dictate the filler type. Its chemistry (sensitivity to O₂, heat) dictates the supporting processes (purging, pasteurization). Its value and regulatory status dictate the level of precision and control (net weight, aseptic design).

Components of Bottling Line Equipment

There are multiple components of bottling line equipment, such as bottle unscramblers, rinsers, filling, and capping machines. Here’s a detailed description of each:

Bottle Unscrambler

Bottle unscramblers are machines designed to consistently organize and orient disordered bottles. The bottles enter their position via the pushing force of the rotating disc.

In addition, the turning bottle device mechanism, along with airflow, sets the bottles in a mouth-up position. Once this is done, the ordered bottles are then carried for the next process using a conveying system.

Rinser

Rinsers, as the name indicates, clean the inside of empty bottles before they are filled with the desired product. Their work is quite simple; bottles are fed into the rinser, where they are held or clamped in an inverted position.

Often, a flushing nozzle sprays clean filtered water or cleaning solution into the bottle. The bottle is then drained and even shaken to dislodge any remaining particles.

Filling Machine

Filling machines are designed to automatically fill a predetermined quantity of a substance or liquid into a bottle. A valve controls the flow of liquid, which varies depending on its viscosity.

Sensors and other control mechanisms are also present to ensure that only the correct amount of liquid is dispensed in each bottle. Common filling machines in a bottle line include gravity and pressure models.

Sealing or Capping Machine

In bottle line equipment, sealing or capping machines seal bottles often with a cap or other closure. The primary goal is to prevent leakage so the bottle contents don’t spill out.

As far as the working is concerned, the bottle passes through the electromagnetic induction machine.

An electromagnetic field heats the foil liner in the cap. This heat quickly melts the polymer layer, making a strong bond with the bottle’s rim and creating an airtight seal.

Types of Bottling Line

Modern bottling lines are customized to suit the needs of each industry, ranging from wine to beverages and water. Let’s discuss the different types of bottling lines you’ll come across:

Beverage Bottling Line

Beverage bottling lines are also a series of equipment that work together to fill, cap, and label beverage bottles, preparing them for efficient distribution.

They often have custom-built servo stretching mechanisms for precise positioning at different speeds. Not only this, but there’s a carbonization control feature that maintains the proper carbonation level in fizzy drinks.

You’ll also see a touch control panel to easily adjust the operating mode, working time, and language. Typical applications of a beverage bottling line include juices, carbonated drinks, and even mineral water.

Wine Bottling Line

Whether you run a boutique winery or are a large-scale wine producer, you must invest in a wine bottling line. These interconnected pieces of equipment are designed to handle the unique needs of the wine industry.

These machines can do everything from delicate packaging to preserving the unique taste of each wine. There’s a fermentation tank that allows wine to age and ferment. Wine filters clarify the wine before bottling, and then it undergoes typical rinsing and filling.

Capping involves putting corkers or cappers on the bottle, depending on its style and type. They serve as a secure seal that protects the wine against oxidation and contamination from external elements.

Why Invest in Bottling Line Equipment?

Having bottling line equipment significantly improves your overall production efficiency. Other than that, it reduces your cost and improves product quality. Let’s discuss these benefits in detail:

Incredible Consistency

When you manually fill each bottle, there’s a high risk of inconsistencies. The amount of product in each bottle may not be precise – either it’s too low or filled to the brim.

As a result, you experience issues during shipping and have unsatisfied customers. However, one of the major benefits of a bottling line of equipment is that it significantly improves your quality control.

It ensures that every bottle has the same quantity of liquid and that there’s no deviation in weight, volume, or level. You enjoy amazing consistency and little to no errors in filling.

Increased Production Speed

Another benefit of investing in bottle line equipment is that it increases your production speed. How? Well, manual filling isn’t only prone to errors but also takes significant time.

On the other hand, a filling machine with 16 fill heads can reach a relatively high speed of 120 bottles per minute.

The high production speed enables you to launch new products to the market quickly and keep up with customer demands. As a result, you maintain a competitive edge, and your customers are also satisfied.

Reduce Costs

Running a business often requires hefty initial investments. Labor costs and extensive equipment maintenance can further exacerbate the financial stress.

Nonetheless, bottling line equipment takes over most of the laborious tasks, from cleaning bottles to filling them with liquid.

This helps you save money on labor costs. Not only this, but industrial bottling equipment tends to last for years, so you don’t have to worry about frequent maintenance or replacement.

Versatility

Bottling line machines truly shine due to their amazing versatility. They don’t handle only one type of bottle or product. Instead, you can adjust their parameters to handle any type of product, whether it’s thin or thick, in any specific measurements.

For instance, the machines can fill sauce bottles and juices without any hassle. This versatility is quite important if your business runs multiple lines of production and launches different products to reach the maximum number of customers.

Extended Shelf Life

Contamination from the air and other external elements can lead to quick product spoilage. Hence, you end up with financial loss, product recalls, and even severe damage to the brand’s reputation. The best part is that the bottling line machines resolve this issue.

For instance, the capping station quickly and accurately attaches lids or caps to bottles, creating a hermetic seal. This doesn’t let contaminants enter the bottle, retaining the product’s freshness and flavor and extending its overall lifespan.

On top of all this, many bottling line equipment come with built-in safety and quality control features. They ensure your bottles comply with industry standards and regulations, safeguarding both the products and overall reputation. There are no discrepancies in the size, color, weight, and shape of the product, so your products always meet customer expectations.

FAQs

How do you choose the right bottling line equipment?

To choose the right bottling line equipment, you must consider your production volume, product characteristics like viscosity, and overall budget. Also, ensure the supplier or equipment manufacturer offers a warranty so your investment is secure.

What factors should you consider when installing bottling line equipment?

When installing bottling line equipment, you should consider choosing the right location and assembly, connecting to a suitable power source, and performing a test operation.

What is the future of bottling line equipment?

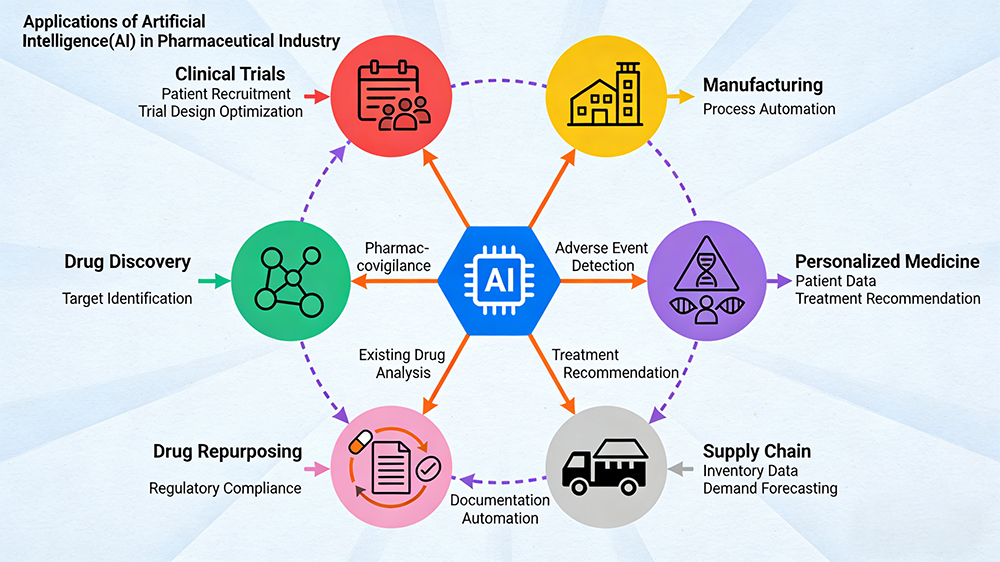

The future of bottling line equipment involves the use of AI and IoT sensors to enhance production efficiency and reduce waste.

Conclusion

Setting up bottling line equipment is indeed a good step for businesses of all sizes. However, if you are looking for reliable and affordable bottling equipment, Finetech has you covered. Get in touch with us today to explore our massive range of certified and industrial-grade equipment!

1 thought on “Bottling Line Equipment | Process and Types”

Grear Article, thank you for sharing