FSD Laboratory Bin Blender

A Laboratory Bin Blender is a precision-engineered device used in research, development, and small-scale production to achieve a uniform, homogeneous mixture of dry, solid powders and granules. It is the smaller, bench-top counterpart to large industrial bin blenders, designed for accuracy, flexibility, and repeatability in a controlled lab setting.

Need a Custom Quote?

Or More information About this product? Contact our sales stuff today!

Key Features

Technical Data

Machine Details

FAQ

Application Powder Types

- PLC auto-control, man-machine interface operation.

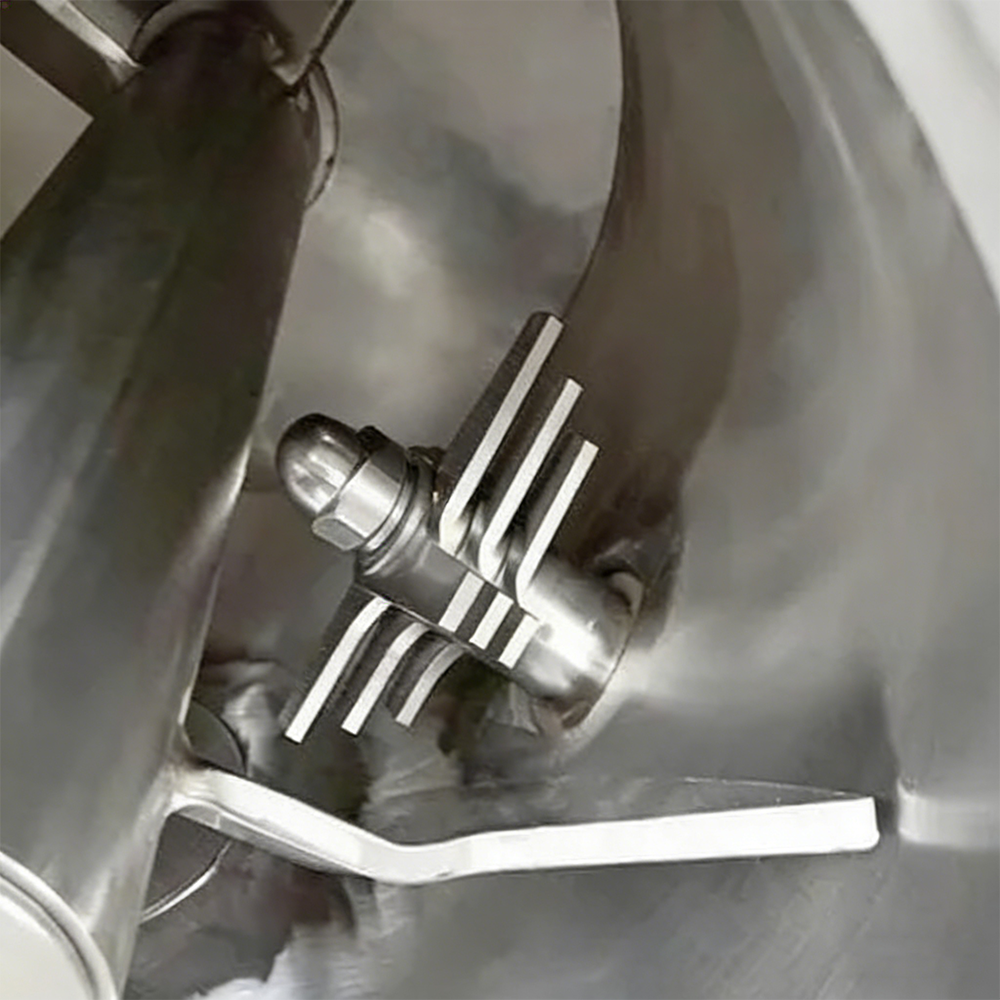

Laboratory Bin Blender Diagram. - Mechanical interlocking fence protects mixing area.

- Safetyinterlocks: vertical positioning, start-stop deceleration, etd.

- Replaceable hoppers for differential mixing volume need.

- Mixing hopper:high-quality S304 stainless steel.

- EU, CE certified to guarantee excellent quality.

- Meets GMP requirements for pharmaceutical production.

| Model | Dimensions | Net Load | Mixing speed | Total power | Equipment weight | |||||

| W1 | W2 | H1 | H2 | H3 | L | Kg | rpm | Kw | Kg | |

| FSD50 | 1538 | 1300 | 1023 | 400 | 650 | 1282 | 25 | 3-15 | 0.37 | 180 |

| FSD100 | 1870 | 1300 | 1234 | 500 | 700 | 1514 | 50 | 3-15 | 0.75 | 240 |

| FSD150 | 2060 | 1465 | 1481 | 600 | 800 | 1600 | 75 | 3-15 | 0.75 | 260 |

| FSD200 | 2152 | 1540 | 1443 | 465 | 800 | 1805 | 100 | 3-15 | 1.1 | 320 |

A Laboratory Bin Blender is a precision mixing machine used primarily in R&D, QA/QC, and small-scale production. It is designed to achieve a homogeneous, uniform blend of dry powders, granules, and other free-flowing solid materials. Common applications include pharmaceutical formulation development, food & beverage testing, chemical research, and cosmetic powder mixing.

It operates on the principle of gentle tumbling or diffusion mixing. The material is loaded into a sealed container (the "bin"). This bin is then securely attached to a rotating frame. As the frame rotates, the bin tumbles end-over-end or at an angle, causing the particles to repeatedly cascade and fold over each other, creating a consistent blend without high shear or heat generation.

Uniform Blending: Excellent for cohesive and free-flowing powders.

Gentle Action: Prevents particle degradation, attrition, or separation of fragile materials.

Contamination-Free: Sealed bins eliminate cross-contamination and product loss.

Easy to Use & Clean: Bins are removable, making loading, unloading, and cleaning simple.

Scalability: Blending parameters from the lab scale can be directly correlated to larger production-scale bin blenders.

Bins come in various materials to suit different product needs:

Stainless Steel (SS 304 or 316L): Standard for most applications, durable, and easy to clean.

Polymers (e.g., Polycarbonate, UHMW): Excellent for corrosion resistance, lightweight, and visual blending observation.

Specialty Coatings: Options like Teflon® or electropolished finishes for sticky or highly pure products.

For optimal blending, the bin should typically be filled between 30% and 70% of its total volume. This ensures enough headspace for the material to tumble and mix effectively. Always consult the manufacturer's guidelines. Common lab sizes range from 1-liter to 50-liter bin capacities.

Blend time varies based on material characteristics (density, particle size, flowability) and the required homogeneity. It can range from 5 to 30 minutes for most applications. We recommend conducting a blend uniformity study to determine the optimal time for your specific product.

Yes. We offer various customization options, including:

Custom bin sizes, shapes, and materials.

Specialized seals (e.g., silicone, PTFE) for containment.

Integration with loading/unloading stations, sieves, or sensors.

Explosion-proof motors for hazardous environments.