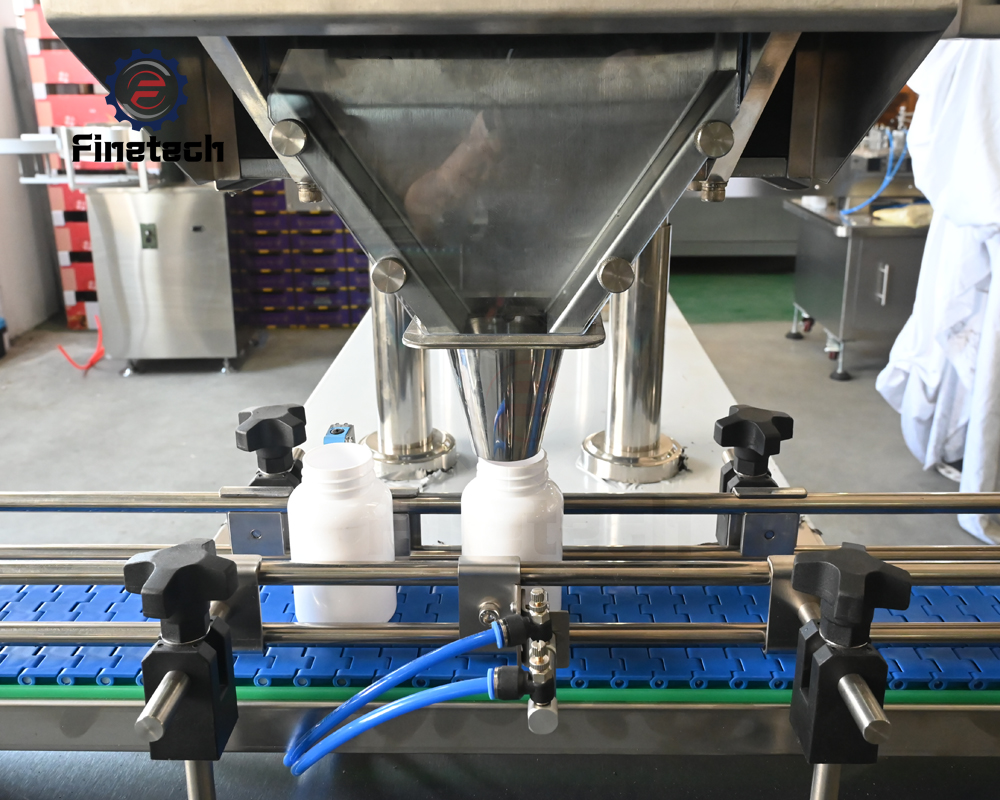

FT-8 Automatic Capsule Counting Machine

This automatic counting machine uses a high-response programmable controller and advanced photoelectric sensing technology from Europe and the United States. It has an attractive design and is easy to maintain. Widely used in the production of vitamins, health supplements, food, pesticides, and chemical industries, it features intelligent electronic detection, supports multi-channel independent counting, and works well with high-speed production lines. The machine meets GMP and FDA cleanliness standards.

Need a Custom Quote?

Or More information About this product? Contact our sales stuff today!

Key Features

Technical Data

Machine Details

FAQ

Application Pill Types

1. Rotatable color touchscreen with HMI interface for easy operation.

2. Simple automatic production parameter setting system covers a wide range of pharmaceuticals.

3. Working status detection and fault alarm system.

4. Photoelectric sensor dust adjustment and self-diagnosis function ensure counting accuracy; features layered tablet ejection function.

5. Secondary and tertiary DC variable frequency vibration control system provides stable and fast counting drive.

| Model | FT-8 |

| Capacity(Tablets/Min) | 4000 |

| Power(kw) | 0.8-0.9 |

| Overall Size(mm) | 1325*1610*1770 |

| Net Weight (Kg) | 760/850 |

An automatic pill counter is an electronic device that uses sensors, vision systems, or precise mechanical mechanisms to count and dispense solid oral dosage forms (tablets, capsules, softgels, lozenges) with high speed and accuracy, replacing manual counting.

Most machines use one of these primary technologies:

Vibratory Feed with Optical Sensor: Pills are vibrated down a chute and pass through a laser/optical beam; each break in the beam counts a pill.

Tray-Based ("Scoop") Counting: A tray with precisely sized cavities is filled, excess is swept away, and counted pills are dispensed.

Cascade Weighing (Gravimetric): The machine weighs a sample of pills, calculates the average pill weight, and then dispenses by weight to achieve the desired count. This is highly accurate for mixed sizes.

Vision Systems (Advanced): Uses cameras and AI to identify, count, and sometimes inspect pills for defects.

Shapes: Round tablets, oblong/capsule-shaped, irregular shapes.

Sizes: From very small (e.g., prednisone) to large supplements.

Surfaces: Coated, uncoated, shiny, matte, gel capsules.

Fragility: Most can handle standard pills; delicate or chewable tablets may require gentle-feed systems.

Retail & Independent Pharmacies: For filling prescriptions quickly.

Hospital Pharmacies: For unit-dose dispensing and bulk orders.

Long-Term Care (LTC) Pharmacies: Essential for blister card/pouch packing.

Pharmaceutical Manufacturers & Repackagers: For bottling and kitting.

Nutraceutical & Supplement Companies: For bottling vitamins and supplements.

Speed: Counts hundreds of pills per minute.

Accuracy: Typically 99.5%+ accuracy, reducing costly overfills and dangerous underfills.

Efficiency: Frees up pharmacist/technician time for clinical tasks.

Inventory Control: Digital logs aid in tracking.

Hygiene & Safety: Reduces direct pill handling, cross-contamination, and repetitive strain injuries.

No. Standard counters are designed for a single SKU (one type/size/color of pill) per counting cycle. Mixing different pills in the hopper will cause inaccurate counts and potential cross-contamination. Gravimetric counters are the exception and can handle mixed sizes by weight.

High-quality machines boast 99.5% to 99.9% counting accuracy. Accuracy can be affected by:

Pill static or dust.

Irregular shapes/sizes within the same lot (breaking).

Improper calibration or worn parts.

Operator error (e.g., overfilling hopper).

Speeds vary by technology and pill size:

Basic Vibratory Counters: 1,200 - 2,500 pills per minute.

High-Speed Counters: 3,000 - 6,000+ pills per minute.

Tray Counters: Slower but extremely gentle.

Yes, most modern "pharmacy-grade" counters can.

They often feature a touchscreen interface to select drug from a database.

They integrate with Pharmacy Management Systems (PMS) via barcode scanning to pull prescription data.

Many can drive or connect to label printers to auto-print vial labels after counting.

Accuracy & Speed: Match to your volume.

Database & PMS Integration: Critical for pharmacies.

Gentle Handling: Important for fragile pills.

Noise Level: Vibratory counters can be loud.

Ease of Cleaning: Quick disassembly is key.

Size & Footprint: Consider your counter space.

Supplier Support: Warranty, training, and local service.

Automatic: You set the count, press start. It handles feeding, counting, and dispensing into a vial/bottle automatically.

Semi-Automatic: Often a simpler, cheaper unit that counts pills but requires the operator to manually handle the bottle (place it, trigger the count, remove it). Less integrated.

Inaccurate Counts: Clean optical sensor, check for static (use anti-static spray), calibrate, ensure consistent pill size.

Pills Jamming: Adjust vibration settings, clean the track, check for damaged pills or debris.

"No Count" Error: Sensor may be dirty or blocked; check pill is passing through the beam.

Static Cling: Use an ionizer/anti-static bar or increase humidity slightly.

Yes, but with strict protocols. Machines used for CII-CV medications should have:

Secure Access: PIN or password protection.

Detailed Audit Logs: Who counted what, when, and how many.

Accurate Reconciliation: Ties counts to inventory records.

Physical Security: In a secure area. The count log is crucial for DEA compliance.