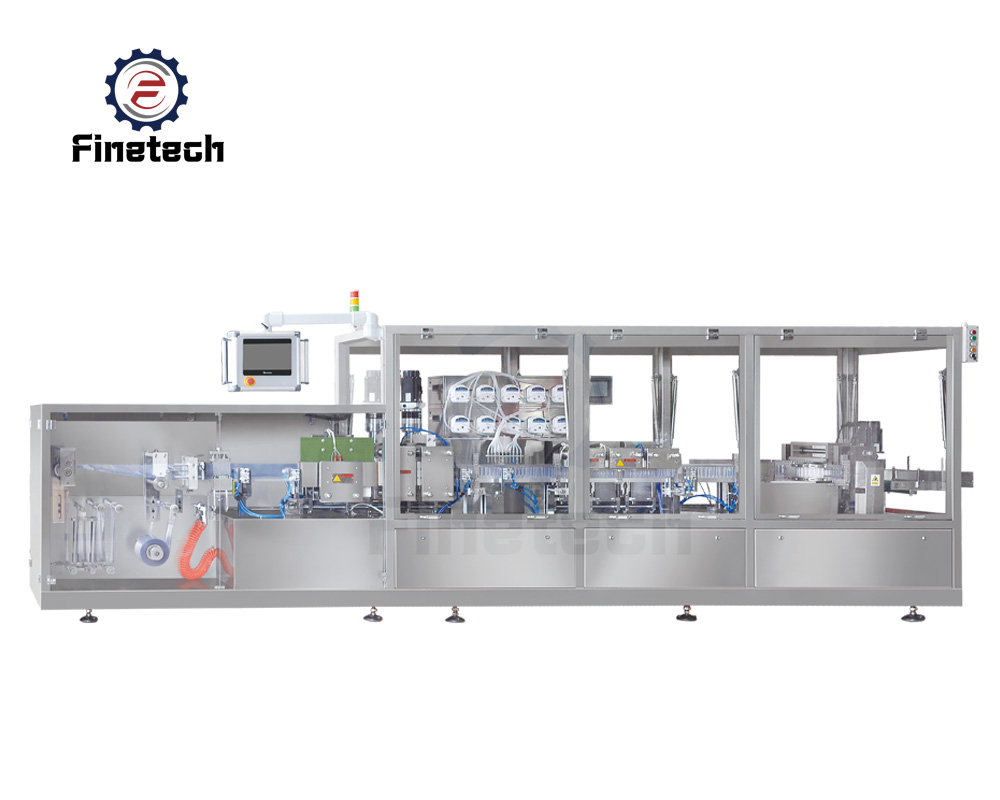

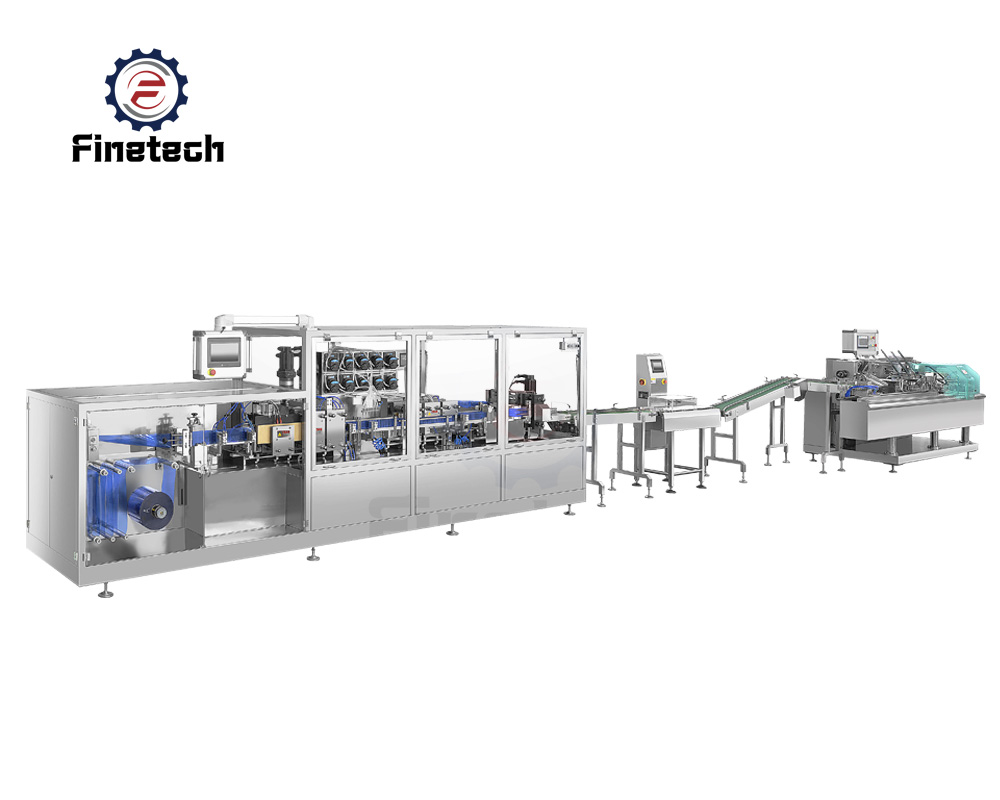

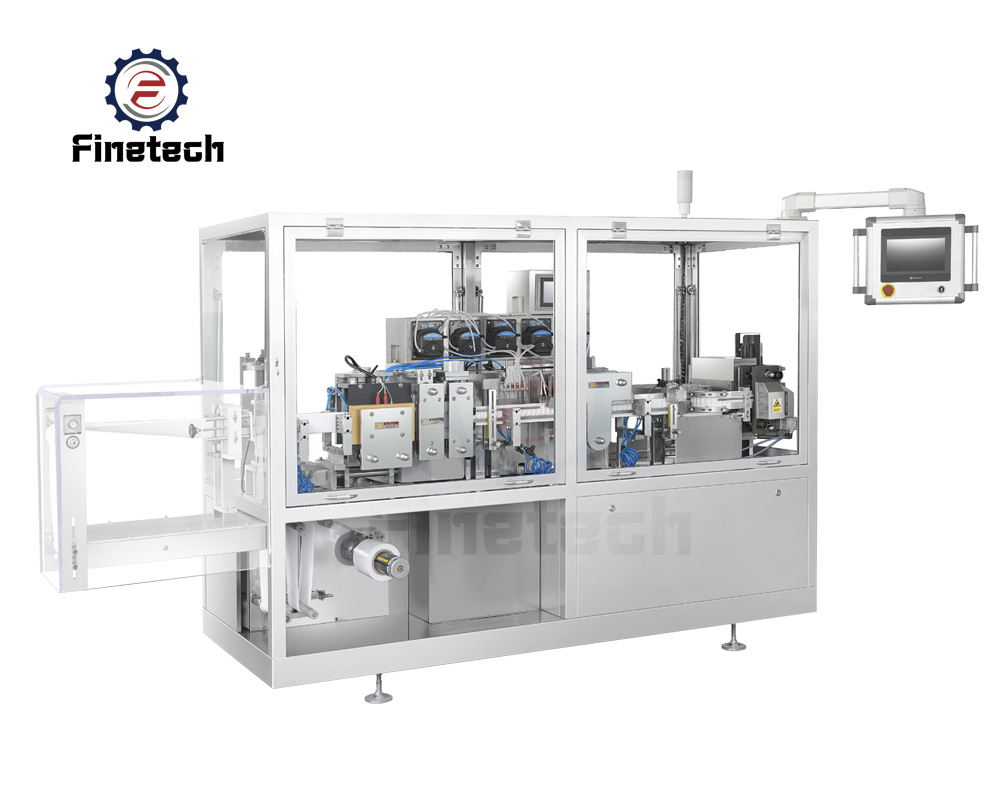

GGS-240P5/P10/15 Plastic Ampoule Filling and Sealing Machine

This fully automatic liquid filling equipment is efficient and accurate, applied for beverage, food, household chemical and other industries; it can fill liquids of various viscosities. It features advanced filling technology and equipped with an electronic dosing system or piston pump to ensure high filling accuracy and fast speed (optional P5/P10/15 filling speed models).

The equipment is stable and easy to operate, and supports multi-specification ampoule bottle adaptation and fully automated production from filling to sealing, greatly improving production efficiency and product quality.

Need a Custom Quote?

Or More information About this product? Contact our sales stuff today!

Key Features

Technical Data

The machine features an HC high-speed controller and stepless frequency conversion speed control with a servo motor to control the film pulling device.

Features an easy-to-use human-machine interface.

Automatic unwinding and film slitting operation with photoelectric front and back pattern registration function.

It uses an easily adjustable electronic peristaltic pump and mechanical piston pump control.

Correct filling accuracy with no dripping, no foaming, and no overflow.

The parts in contact with materials are made of high-quality stainless steel 316L; the body is made of SUS304 stainless steel, meeting GMP standards.

| Model | GGS-240(P5) | GGS-240(P10) | GGS-240(15) |

| Max forming depth | 12mm | 12mm | 12mm |

| Punch frequency | 0-25time | 180-250time/pre | 25time 22000units/h |

| Packing material | PVC/PE,PET/PE(0.2-0.4)140xmm | PET/PE,PVC/PE,PVE/EVOH | PET/PE, PVC/PE,PVE/EVOH |

| Filling volume | 1-50ml | 1-100ml | 1-100ml |

| Toal power supply power | 7KW | 22KW | 22KW |

| Voltage | 380V/50Hz | 380V/50Hz | 380V/50Hz |

| Machine weight | 1200Kg | 2000Kg | 3000Kg |

| Overall dimension (L*W*H) | 3200x850x1400(mm) | 5200x1050x1800(mm) | 7300x1050x1800(mm) |