Granulation Line For Solid Dosage Form

Our Solid Dosage Granulation Line is major technology for solid dosage forms of pills. It has high technical requirements for drug powders and granules before forming tablets and capsules. Therefore, Finetech provides you with a comprehensive solid dosage form pharmaceutical solution, applicable to pharmaceutical, healthcare, and food factories.

Need a Cutsom Quote

Or More information About this product? Contact our sales stuff today!

Key Features

FAQ

Application

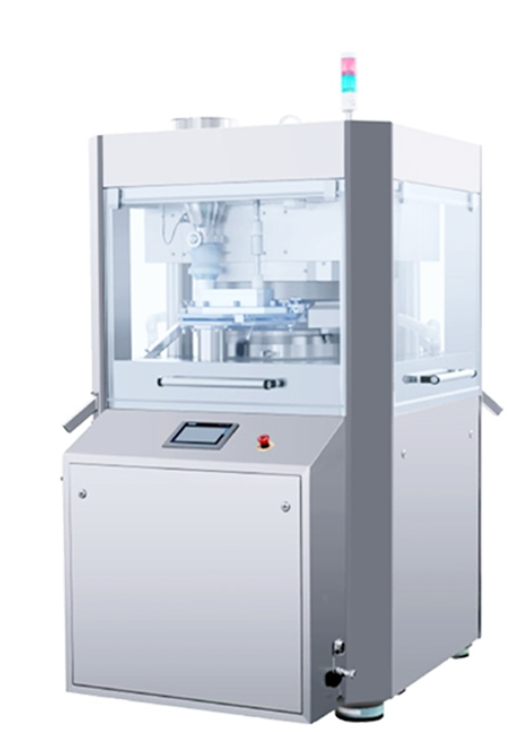

Granulation line equipment

Finetech’s granulation line is high-functioning technology for producing pharmaceutical solid dosage forms. Since there are stringent quality requirements for the content uniformity of the formed granules and their physicochemical properties, it is crucial to choose the right process. The wet granulation process ensures that fine powder heterogeneous mixtures are transformed into uniform granules with larger particle sizes and higher density.

Capacity range: 25L to 1,500L

Granulation process: wet granulation and fluidized drying

Wet Granulation: Uses liquid binders (e.g., water, ethanol).

Dry Granulation: Compaction (roll compaction/slugging).

Melt Granulation: Heat-activated binders (e.g., PEG).

Wet: For cohesive powders, improves flowability.

Dry: For moisture-sensitive APIs (avoids heat/liquid).

Melt: For heat-stable APIs with thermoplastic binders.

Start with 5–20% binder solution (varies by formulation).

Adjust nozzle pressure/spray pattern for uniform coverage.

Too Hard: Excessive binder/over-granulation.

Too Soft: Insufficient binder/under-drying.

Adjust milling screen size (smaller = smoother granules).

Add glidants (e.g., colloidal silica) in final blend.

After each batch (GMP requirements).

Deep clean weekly (disassemble contact parts).

GMP/WHO for pharmaceuticals.

ATEX (for explosive atmospheres).

FDA 21 CFR Part 11 (if using digital records).

DQ/IQ/OQ/PQ (Design/Installation/Operational/Performance Qualification).

PAT (Process Analytical Technology) for real-time monitoring.