The pharmaceutical industry produces billions of bottled medicines every year, but the margin of error is next to none. The integrity of every medication; from life-saving injectables to commonly prescribed syrups, relies entirely on the standards of the manufacturing process. This critical level of quality control is supported by pharmaceutical bottle filling machinery.

More than filling and packaging, pharmaceutical bottle filling machines protect global public safety. If you are a manufacturer responsible for producing liquid drugs, these machines can help you meet high-volume production demands while maintaining absolute dosage accuracy and strict regulatory compliance.

Here is everything you need to know about pharmaceutical bottle filling machines. Learn how this machine makes pharmaceutical production both safe and scalable.

Key Takeaways: Pharmaceutical Bottle Filling Machine

- Purpose and Function: By automating liquid filling, this machine reduces errors, cuts waste, and keeps pharmaceutical lines compliant and safe.

- System Design: Built with coordinated mechanical and electronic components including feeders, conveyors, pumps, and sensors that keep every stage in sync.

- Process Coordination: Each bottle moves through cleaning, filling, and sealing steps under strict hygienic conditions to maintain pharmaceutical-grade purity.

- Industry Value: Enables large-scale, contamination-free production while meeting regulatory standards and cutting overall operational costs.

What are Pharmaceutical Bottle Filling Machines?

Pharmaceutical bottle filling machines are specialized equipment designed for the pharmaceutical and biotechnology industries. They are used to precisely and accurately fill containers with medications or other fluids, such as syrups, injectable liquids, and suspension formulas. The entire process is carried out through a highly automated system that measures, dispenses, and seals the product.

These machines help you maintain dosage accuracy, prevent product contamination, and handle a wide range of viscosities for high-volume production. They are an integral part of pharmaceutical production for meeting strict regulatory and sterile filling requirements.

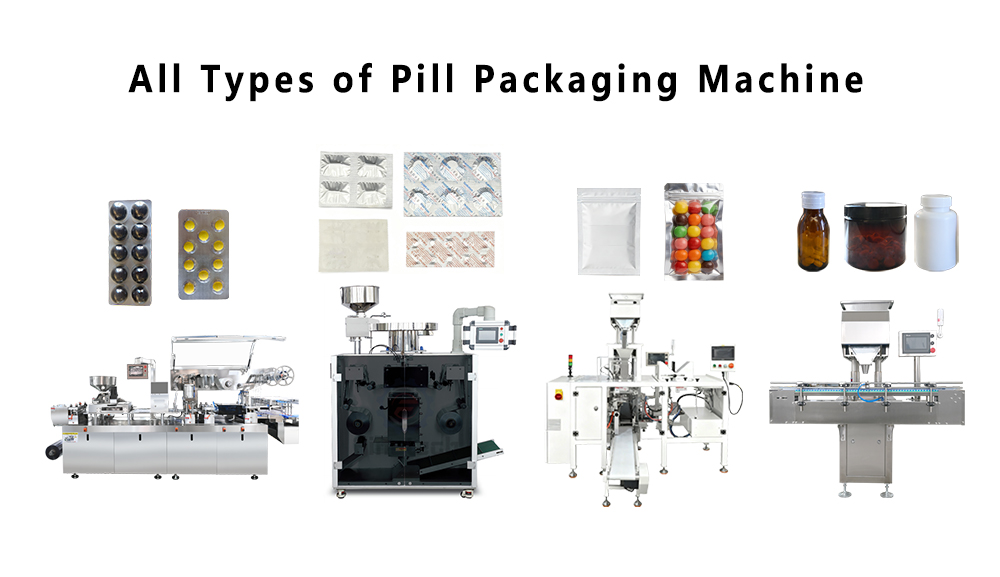

Three Types of Pharmaceutical Bottle Filling Machines

Pharmaceutical bottle filling machines are categorized primarily based on their level of automation and the specific filling principles. We will examine the key filling methods individually to understand how each is best suited for different pharmaceutical liquids and production requirements.

1. Gravity Filling Machine

Gravity filling machines are among the most basic and low-cost bottle filling machines available. This method uses the force of gravity to transfer liquid from an overhead supply tank into containers positioned below. The gravity filling machine comes with its own benefits:

- Best suited for modest to medium capacity manufacturing needs.

- The process relies on gravity and consumes less energy than other methods.

- Simple design allows for quick and straightforward changeover between different bottles and product types.

2. Volumetric Filling Machine

Volumetric or piston liquid filling machines dispense a specific volume of product into bottles through a piston-cylinder system. The movement of the piston determines the exact amount of liquid drawn from a hopper and then releases it into the container.

The accuracy and consistent fill volumes make it ideal for the pharmaceutical industry, where dosage is critical, such as in an ampoule filling and sealing machine. This machine offers several advantages:

- Suitable for a wide range of viscosities, from thin liquids to thick creams and pastes.

- Excellent option for large volume manufacturing.

- Avoid over- or under-filling and reduce product wastage.

3. Vacuum Filling Machine

Vacuum filling machines work by creating a vacuum pressure to fill containers with liquid or semi-liquid products. This process evacuates air from the container and then draws the product through a nozzle until it reaches the required level. These versatile machines are utilized in various industries, including food, pharmaceuticals, and cosmetics. Here are some of its key benefits:

- Best for low-viscosity, non-foaming liquids, like water-thin solutions, spirits, and thin oils.

- The vacuum prevents dripping and splashing and provides clean, spill-free fills.

- Ensures all bottles have an identical visual fill height.

Core Components of Pharmaceutical Bottle Filling Machines

Certain core components and parts are common across all pharmaceutical bottle-filling machines. These integrated parts work in conjunction with other bottling line equipment to ensure a smooth production and packaging process. Let’s take a look at their key parts and their functions:

1. Product Hopper

The product hopper is a storage tank that holds the bulk liquid before it is dispensed into the bottles. It is usually constructed from high-grade stainless steel (often 316L). This material choice is critical to ensure that the container is non-reactive, non-corrosive, easy to sterilize, and resistant to chemical cleaning agents.

2. Filling Nozzles

Filling nozzles are the critical components where the product exits the machine and is dispensed into containers. They control the flow of the liquid or cream into the bottles. The nozzle design varies significantly based on the product’s characteristics.

For instance, a liquid filling machine used for a pharmaceutical cough syrup might utilize a diving nozzle. This type of nozzle descends into the container during the fill cycle and gradually retracts to control foaming and splashing. Many nozzles feature an anti-drip mechanism that prevents leftover product from dripping between fills.

3. Filling Mechanism

The filling system is responsible for accurately measuring and filling the correct dose of the product. This mechanism uses a combination of different valves, pumps, and pistons to execute the fill cycle. The synchronization of these components guarantees the accurate dosage required for different products.

4. Sealing and Capping System

The sealing and capping system applies and secures a closure to the filled bottles. It involves different processes: applying a screw cap with a specific torque, inserting a rubber stopper into a vial, or applying an induction seal to create an airtight barrier.

5. Conveyor System

A conveyor system is a synchronized assembly of moving belts and slats made of pharmaceutical-grade stainless steel or low-friction plastic. It is responsible for the continuous movement of bottles, starting from the initial feeding area to labeling and packaging.

This system maintains the speed and spacing between bottles at each step without jams or breakage.

How A Pharma Bottle Filling Machine Works?

A pharmaceutical bottle filling machine operates by synchronizing different core components in a series of steps. Here is how it works:

Step 1: Bottle Infeed

The process starts with the feeding of empty, washed, and sterilized bottles into the conveyor belt. It initiates the production cycle and maintains a continuous supply of containers into the machine.

Step 2: Bottle Alignment & Positioning

As the bottles move down the conveyor, an indexing wheel or timing screw separates and positions the bottles under the nozzles. This step is important to make sure that each bottle is perfectly centered and ready to receive the product.

Step 3: Liquid Dispensing

This step is where the pre-programmed filling mechanism (e.g., piston, time-pressure, or gravity) activates. The pharmaceutical liquid is dispensed through the anti-drip nozzles into the containers in a specific dosage. Once filled, the bottles are released from the mechanism and moved further down the line.

Step4 : Capping & Sealing

All filling steps image from: https://www.youtube.com/watch?v=XjhqU5L4fG0

The filled bottles are transported to the capping and sealing station. Here, a cap, stopper, or seal is applied to the bottle to ensure an airtight closure and maintain product sterility. A proper seal is mandatory for regulatory compliance and to extend the product’s shelf life.

Key Features and Benefits of Using Bottle Filling Machines

Pharmaceutical bottle filling machines go far beyond simply dispensing liquid. They are critical for maintaining product integrity, reducing waste, and automating the entire packaging process. Here are some key features and benefits these advanced systems provide:

1. Sterile Filling

Research shows that medicinal products, particularly injectable liquids and syrups, can be contaminated during manufacturing and packaging. The World Health Organization (WHO) warns that children under five are especially vulnerable to serious illnesses from consuming contaminated syrups.

These filling machines support sterile filling by operating within sealed, clean room-compatible environments and using aseptic materials. This minimizes human intervention and exposure to airborne particulates, hence preventing contamination.

2. Precision & Accuracy

Pharmaceutical bottle filling machines use advanced sensors for highly accurate and consistent filling volumes. It minimizes costly overfilling and prevents underfilling, which can compromise therapeutic dosing. Achieving this level of accuracy guarantees patient safety and protects the manufacturer’s bottom line.

3. Automation

If you opt for an automated system, the machinery controls the entire bottling process, including feeding, aligning, filling, and capping. This comprehensive approach helps you save on labor costs, reduce cycle time, and increase overall output capacity. Additionally, automated processes deliver a consistent result, which leads to fewer errors as compared to manual handling.

4. Regulatory Compliance

The Current Good Manufacturing Practices (cGMP) and FDA regulations govern pharmaceutical production. These regulations demand a high level of quality assurance, process control, and documentation. The controlled and repeatable process provides you with all the necessary validation and traceability for market approval and safety audits.

FAQs

1. What are the core components of a pharmaceutical bottle filling machine?

Key components include the liquid reservoir, dosing pump or filling nozzle, bottle conveyor, capping unit, control panel, and safety interlocks.

2. Can a single machine handle different bottle sizes?

Yes, most machines are adjustable and can accommodate various bottle heights and diameters with quick-change parts or programmable settings.

3. Is it possible to integrate a pharmaceutical bottle filling machine with serialization systems?

Yes, modern machines can be integrated with serialization and track-and-trace solutions for compliance with anti-counterfeiting regulations.

Why the Right Partner Matters in Pharmaceutical Production

Well-chosen pharmaceutical bottle filling machines can be a valuable investment for your manufacturing success. More than speed, they build uncompromising safety and regulatory confidence directly into your production line.

However, there’s another factor that matters just as much: the company you choose. A machine is only as good as the support, installation, and training that come with it. Without the proper guidance, even the best equipment can fall short.

At Finetech, we offer all of that and more. Our team also provides on-site machine training to ensure your operators know exactly how to get the best performance from your equipment.

Visit our website to see our pharma machines in action and discover what sets Finetech apart.