SOP for Ointment Filling Machine

1.0 OBJECTIVE: This document lays out how to operate the Ointment Filling Machine properly. The goal is making sure we

By exporting our high-quality pharmaceutical manufacturing and process equipment from China, we can provide you with complete pharmaceutical solutions.

We offer a complete line of pharmaceutical production machinery, from raw material processing to finished tablets or capsules after mixing and granulation.

The universal crusher is the first step in pharmaceutical production. The raw materials are crushed and discharged through the crushing chamber. Various crushed particle sizes can be obtained by using screens of different mesh sizes, all of which meet GMP requirements.

High-Speed Rapid Mixer Granulators (RMG) are advanced industrial machines designed to integrate mixing, wet/dry granulation, and homogenization in a single closed system. The machine combines high-shear mixing (via rotating impellers and choppers) with granulation, enabling efficient particle size control and the uniform blending of powders, binders, or solvents.

A Fluid Bed Dryer (FBD) is an industrial drying system that uses fluidization technology to efficiently reduce the moisture content of granular or powdered materials.

Fluidization Process: Material is placed on a perforated bed; heated air/gas is forced upward through the bed, lifting and suspending particles in a fluid-like state. This maximizes the heat and mass transfer for uniform drying.

The powder mixer combines a variety of powder ingredients: pharmaceuticals, chemicals, food additives, etc. It is used for products which require the mixing of wet and dry materials; it utilizes rotating blades, ribbons, or paddles to create a shearing force and convective motion, ensuring thorough blending.

A Rotary Tablet Press is a high-speed industrial machine which compresses powdered or granular materials into uniform tablets. Widely used in pharmaceutical, food, and chemical industries, it combines precision and efficiency for mass production.

The tablet or pill coating machine is used to apply a film/coating of sugar or other materials on the tablet to improve its taste. It is commonly used in pharmaceutical, food and chemical industries.

The capsule filler is one of the core machines in our pharmaceutical production equipment series. We provide customers with semi-automatic and fully automatic NJP-series machines to meet the needs of capsule filling, from low to high speeds.

Also include the capsule Auxiliary equipment.

A softgel maker, also known as a softgel encapsulation machine, is specialized pharmaceutical equipment designed to encapsulate liquids, gels, oils, or semi-solid substances into soft gelatin capsules.

It is best used for:

Pharmaceuticals: Encapsulating oils, suspensions, or heat-sensitive APIs.

Nutraceuticals: Producing vitamin supplements, fish oil capsules, etc.

Get the latest pharmaceutical equipment industry knowledge and trends from our list of resources to help you run your business better.

1.0 OBJECTIVE: This document lays out how to operate the Ointment Filling Machine properly. The goal is making sure we

Standard Operating Procedure of Tube Filling Machine 1.0 OBJECTIVE: This SOP tells you how to run the Tube Filling Machine

Tablet manufacturing demands exceptional quality and compliance standards. This requires high precision and careful checks, as even the smallest defect

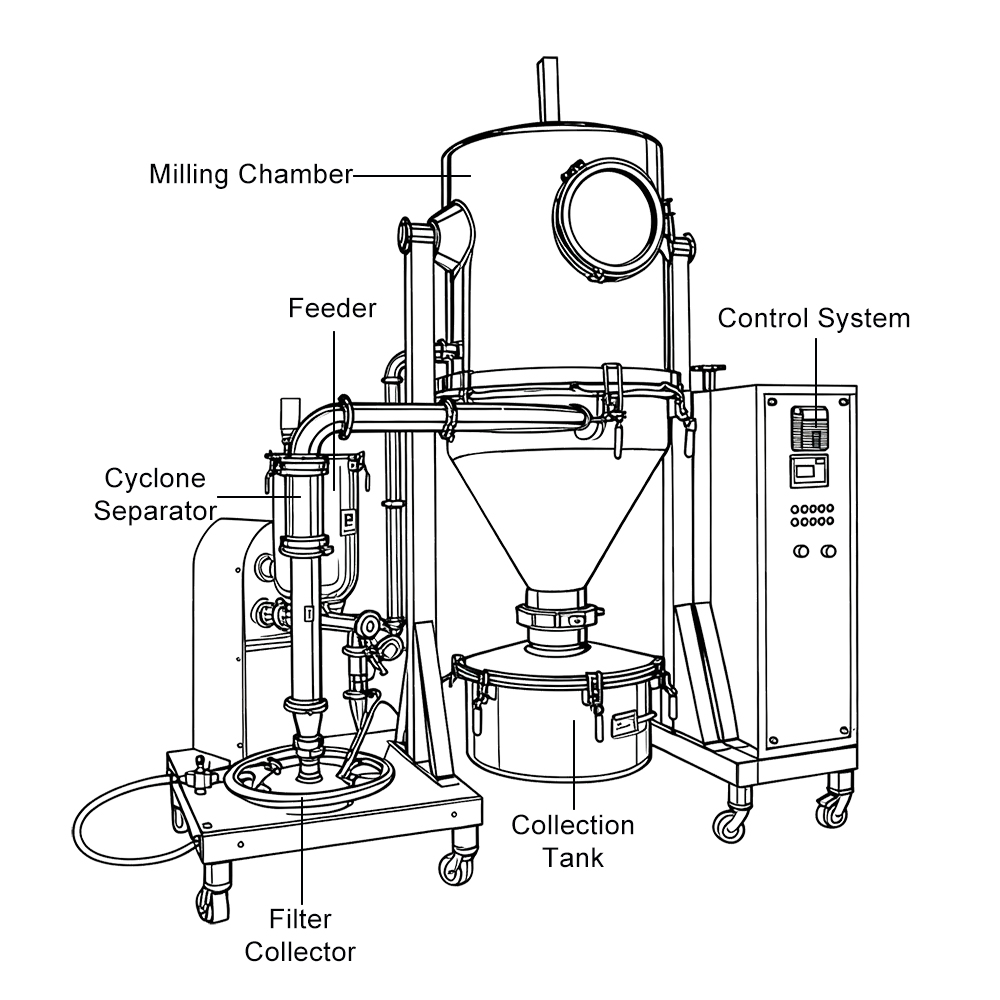

If you’ve ever wondered how pharmaceutical companies create perfectly uniform powders, the answer is the pharmaceutical jet milling machine. In

Here are some frequently asked questions about pharmaceutical manufacturing equipment.

Tablets, capsules and granules.

Equipment must adhere to GMP guidelines, including:

You can select and customize the appropriate pharmaceutical manufacturing equipment based on the properties of your pills, your production capacity requirements, budget, and other comprehensive factors.

Yes, you can send us your factory CAD design and regulatory requirements, and we will plan the equipment and placement of the pharmaceutical production line according to your needs.

WhatsApp us