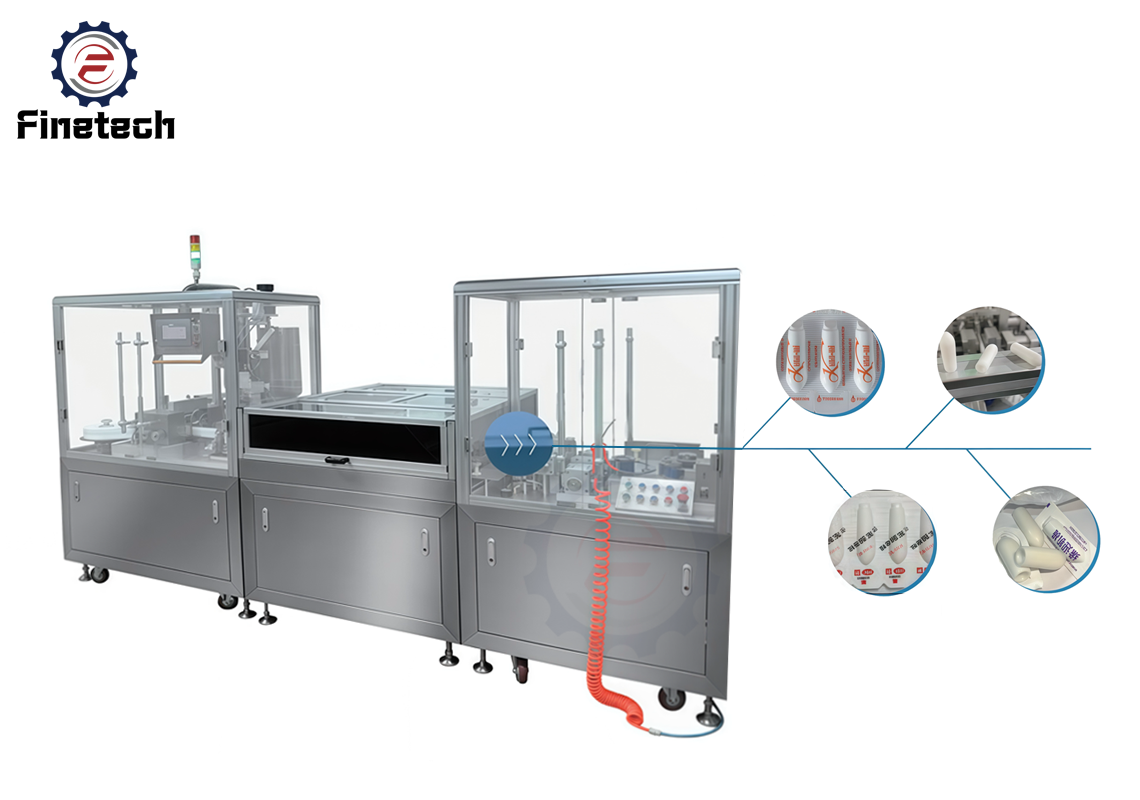

SJ-2L Automatic Suppository Production Line

Suppository production line was designed for the pharmaceutical and healthcare product industry, especially for high-capacity, large-scale continuous production. The production line integrates material mixing, molding, cooling, and demolding. It uses an intelligent control system to ensure accurate dosage and consistent molding. It supports multi-specification mold adaptation, realizes full-process automated production, meets GMP specifications, and is an ideal choice for modern suppository production.

Need a Custom Quote?

Or More information About this product? Contact our sales stuff today!

Key Features

Technical Data

Continuous cooling and shaping. After filling, the suppository shell can be fully cooled and shaped to achieve liquid-to-solid transformation.

Suppository bottles are continuously produced, sealed, and automatically printed; the seal will be intact, the appearance will be neat, and the yield rate will be 98% or greater.

| Model | SJ-2L |

| Output/hour | 5.000-5,000 grains/hour |

| Dosage deviation | <±2% |

| Capacity of the bucket | 20L |

| Gas consumption/per minute | 0.6m³ |

| Working voltage | Three-phase Ac 380V |

| Suitable suppository shape | Bullet head type, torpedo type, duck shape and various other shapes |

| External dimensions | 2270mm*2000mm*1760mm(L*W*H) |

| Applicable matrix | Synthetic fatty acids glycerine, glycerol gelatin, polyethylene glycol, etc. |

| Unit Dose | 0.5-5ml |

| packaging flim | PVC/PE, Thickness: 0.15 mm |

| working air pressure | ≥0.6Mpa |

| Water consumption/per hour | 50kg (recycling) |

| Total power | 3kw |

.png)