Suppository Filler

A suppository filling machine automatically fills and molds medicinal suppositories with precise dosing. It melts the base material, fills molds, cools the products, and ejects finished suppositories for pharmaceutical use.

Learn More About Our Suppository Filler Equipment

Suppository fillers are widely used in the pharmaceutical, healthcare, and cosmetic industries for producing medicated or lubricated suppositories with high accuracy and hygienic standards.

Output: 1,000-2,000 grains/hour

Bucket capacity: 20 L

Total power: 2.5 kW

Output: 5,000 grains/hour

Bucket capacity:20 L

Total power: 3 kW

Specification

| Model | SJ-1L | SJ-2L |

|---|---|---|

| Output/hour | 1,000-2,000 grains/hour | 5,000 grains/hour |

| Dosage deviation | <±2% | <±2% |

| Capacity of the bucket | 20L | 20L |

| Gas consumption/per minute | 0.6m3 | 0.6m3 |

| Working voltage | Three-phase Ac 380V | Three-phase Ac 380V |

| Suitable suppository shape | Bullet head type, torpedo type, duck shape and various other shapes | Bullet head type, torpedo type, duck shape and various other shapes |

| External dimensions | 2300mm*900mm*1800mm(L*W*H) | 2270mm*2000mm*1760mm(L*W*H) |

| Applicable matrix | Synthetic fatty acids glycerine, glycerol gelatin, polyethylene glycol, etc. | Synthetic fatty acids glycerine, glycerol gelatin, polyethylene glycol, etc. |

| Unit Dose | 0.5-5ml | 0.5-5ml |

| packaging flim | PVC/PE, Thickness: 0.15 mm | PVC/PE, Thickness: 0.15 mm |

| working air pressure | ≥0.6Mpa | ≥0.6Mpa |

| Water consumption/per hour | 50kg (recycling) | 50kg (recycling) |

| Total power | 2.5kw | 3kw |

Sample Products

Learn more about our suppository filling machines

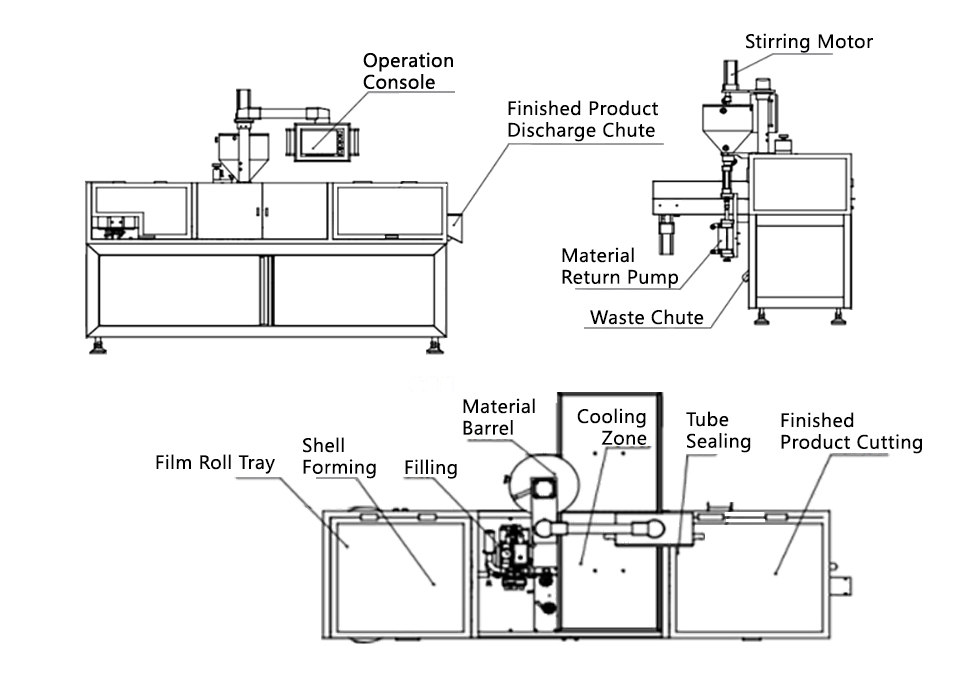

Key Components of Suppository Fillers

Modular design enables fast switching among shapes for flexible production.

Quick Mold Changeover

Vision system automatically detects and removes flawed products.

Automatic Defect Rejection

Automated process management with precise parameter regulation.

PLC Smart ControlHow Does Suppository Filler Work

- Step 1. Raw Material Preparation: Melt base and mix with API; transfer to hopper.

- Step 2. Mold Pre-Treatment: Molds are conveyed to a pre-cooling station where they are cooled to 10-15°C and coated with the release agent (if required); a positioning system ensures precise alignment.

- Step 3. Precision Filling: Dose and fill molds with our multi-nozzle system.

- Step 4. Solidification: Filled molds enter a three-zone gradient cooling tunnel where precisely controlled temperatures ensure complete suppository solidification.

- Step 5. Demolding and Collection: Automatically eject sort pills and remove any defects.

- Step 6. Cleaning and Maintenance: Auto-clean and sterilize, and record data.

FAQ

Our machines are compatible with common bases like cocoa butter, PEG, and glycerin gelatin.

A suppository filling machine is a specialized pharmaceutical or cosmetic manufacturing device designed to accurately dose, fill, and sometimes seal molten mass (containing active ingredients like cocoa butter, polyethylene glycol (PEG), or glycerin bases) into suppository molds. It automates the process for hygiene, speed, and dosage precision.

Clean immediately after production by circulating 80°C purified water for 20 minutes; lubricate moving parts regularly.

Standard models produce 1,000-6,000 suppositories per hour.

Yes, both the materials and the design meet GMP standards.

Manual/Piston Fillers: Operated by hand lever; ideal for R&D, small batches, and clinics.

Semi-Automatic Machines: Motor-driven filling with manual mold handling. Perfect for small to medium-scale production.

Fully Automatic Machines: Integrated automated systems for filling, cooling, ejection, and often printing/cartoning. Used for large-scale commercial production.

Volumetric vs. Peristaltic: Volumetric (piston) pumps offer high accuracy for viscous masses. Peristaltic pumps are used for less viscous masses and minimize cross-contamination.

Primarily the pharmaceutical industry (rectal/vaginal medications). Also used in nutraceuticals (e.g., probiotic suppositories), veterinary medicine, cosmetic/personal wellness (e.g., lubricants, detox products), and CBD/ cannabinoid product manufacturing.

Machine Type & Pump Precision: Piston pumps are generally more accurate.

Mass Temperature & Viscosity: Must be kept constant to ensure uniform flow.

Mold Temperature: Should be lower than the mass to ensure solidification.

Operator Skill (for semi-auto): Consistency in operation.

Calibration: Regular calibration of the dosing unit is critical.

Capacity is measured in molds per hour (with each mold having 60-200 cavities).

Manual: 5-15 molds/hour.

Semi-Automatic: 15-60 molds/hour.

Fully Automatic: 60 to over 300 molds/hour.

Cleaning: Major components (hopper, piston cylinder, nozzles) should be disassembled and cleaned after each batch with appropriate solvents (e.g., hot water, ethanol). CIP (Clean-in-Place) systems are available in advanced models.

Maintenance: Regular lubrication of moving parts, inspection of seals and gaskets, calibration of the dosing system, and checking electrical components as per the manufacturer’s manual.

Critical contact parts (hopper, piston, nozzles, tubing) are usually made of 316/316L Stainless Steel (pharmaceutical grade) or medical-grade PTFE (Teflon). This ensures corrosion resistance, compliance with GMP, and easy cleaning.

Many machines are versatile and can be used for similar semi-solid/solid dosage forms like ovules, pessaries, oral lozenges (troches), or even small cosmetic sticks with the appropriate change parts and temperature settings.

A reputable manufacturer should provide:

Installation & Operational Qualification (IQ/OQ) protocols or assistance.

On-site or virtual training for operators.

Documentation: Detailed manuals, part diagrams, and calibration procedures.

Yes.

Pleaese check and download:

.png 1000w, https://pharmamachinecn.com/wp-content/uploads/2025/07/SJ-1L水印)-600x480.png 600w, https://pharmamachinecn.com/wp-content/uploads/2025/07/SJ-1L水印)-300x240.png 300w, https://pharmamachinecn.com/wp-content/uploads/2025/07/SJ-1L水印)-768x614.png 768w, data:image/png;base64,iVBORw0KGgoAAAANSUhEUgAAAA8AAAAMCAMAAACKnBfWAAAAtFBMVEXy8vTRzNL09Pb////b2927uL3h4eL9+/rx8fHq6urY2dvl5eHt7er09PO6urezsq6RlpHe3tzp6OecmpXt7e339/f5+Pjw8PHb2tmRkI6WmZimqKm4uLPm5ePg39+xsbChoaGioqVscHJnamyJi4qYm5WbnpuNioXX1dLY2NibmpmSk5N/f3+trq2YmJaEhILS0dCBgYGkpKS7u7uoqKiLiYlwcXHPz8+MjIzR0dHn5+fm5uYcWAeCAAAAh0lEQVQI102NyRaCMBAEx7TiuAFRBBc0cUMFQUHE7f//ywM8X+pWfagmagkYULtjAej+nXsM9AfDZiEAGNmOKw0fT2zpialfux/M5oulHYbOCiBgrfRmu9sfouMJIOCs4+TiqjS73gACZKqTvLiXj+oJEGCpMntFRZxX77r3YQ6Y2fuK5s/gBz0hCx9DlC+JAAAAAElFTkSuQmCC 15w)

PID system maintains an optimal melting state, preventing defects.

Precise Temperature Control