Pill Counter Machine Price: What’s the Cost Per Tablet?

Counting pills by hand takes time, and that’s actually a universally known fact. That’s why more pharmacies, clinics, and supplement

Tablet and Capsules counts can be set up within the range of 0-9,999 and assembled into counting lines.

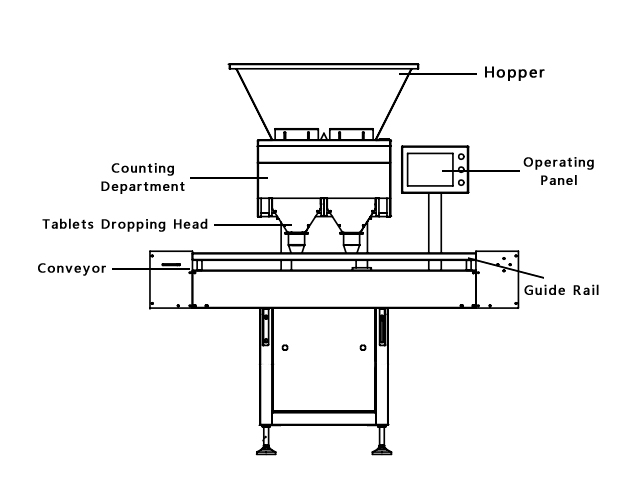

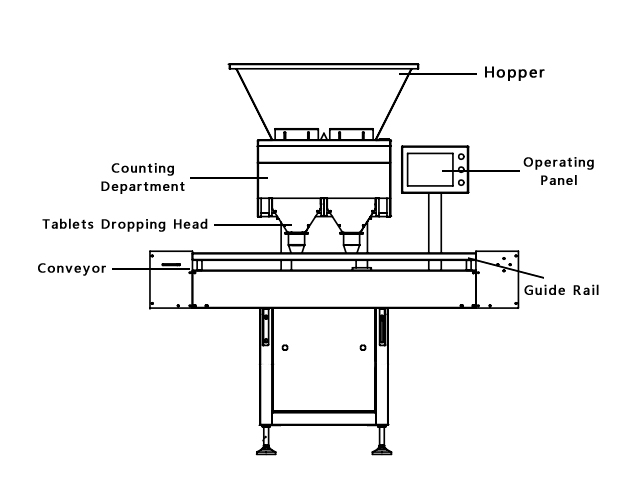

The tablet counting machine is an automated device designed to accurately count and dispense capsules, or tablets in pharmacies, hospitals, and pharmaceutical manufacturing facilities. Reduce human error and save time compared to manual counting.

This high-quality anti-dust machine utilizes computer counting technology, which can accurately count and pack tablets (including custom-shaped tablets), hard capsules, soft capsules, and other solid particles ranging in size from 2 to 25 mm.

This is a high-speed counting device specially designed for the pharmaceutical, food, and health industries. It accurately counts tablets, capsules, and pills with excellent speed and reliability, with a count error < 1%.

This machine features high dust resistance and electronic counting technology, allowing it to count and pack tablets (including irregularly shaped tablets), hard capsules, soft capsules, pills, and other solid dosage forms with a size range of 2-25 mm. It can bottled, boxed, or bagged, fully complying with GMP requirements, and is particularly applied for research institutions, hospitals, newly established small pharmaceutical factory and healthcare factories.

The bottle blocking device on the feeding track of the bottle conveying mechanism blocks the bottles sent by the upper equipment at the bottling position and holds them for filling. The pills reach the medicine warehouse in a controlled manner through the vibration of the corrugated feeding plate. The medicine warehouse is equipped with a photoelectric sensor for counting. The drugs falling into the medicine warehouse are quantitatively counted by the photoelectric sensor and loaded into the bottles at the bottling position.

Finetech’s Tablet Counting Line is an advanced, automated system designed for high-speed counting, filling, and packing of tablets, capsules, or pills in pharmaceutical manufacturing, packaging facilities, and large-scale pharmacies. These systems ensure precision, efficiency, and compliance with regulatory standards such as GMP, and FDA.

This is a doypack machine combined with an electronic counting system. Avaliable count tablets, capsules, candy, and other solid dosage forms.

| Model | FT-2 | FT-2A | FT-4 | FT-8 |

|---|---|---|---|---|

| Capacity(Tabs/Min) | 1000-1800 | 1000-1800 | 2000-3500 | 4000 |

| Power(kw) | 0.15 | 0.15 | 0.15 | 0.8-0.9 |

| Overall Size(mm) | 810*720*840 | 900*660*760 | 920*740*880 | 1325*1610*1770 |

| Net Weight (Kg) | 65 | 85 | 78 | 760/850 |

304 stainless steel is available for parts that have contact with medicine.

Discharge Outlet

Our daily production capacity can reach 50 units, which can meet your needs for large-scale supply.

Bulk Supply Capability

We provide complete packaging line solutions for capsule counting machines.

Counting Line Equipment SupplyDeeply understanding the function, standard operating procedure(SOP), and price range of tablet counters.

Counting pills by hand takes time, and that’s actually a universally known fact. That’s why more pharmacies, clinics, and supplement

A capsule counter SOP document is a GMP requirement that controls how capsule counting must be performed in a pharmaceutical

Many industries rely heavily on specialized equipment to maintain the quality of their products. When you’re dealing with things like

Do you ever wonder how companies count pills so well? They use a special machine called a capsule or tablet

We provide Manual/Semi-Automatic and Fully Automatic capsule counting machines.

Yes, our capsule counting machines are highly accurate when used correctly, but occasional verification (manual checks) is recommended for critical applications like pharmaceuticals.

Daily: Clean with a soft brush & isopropyl alcohol (avoid letting moisture in).

Weekly: Check sensor alignment & vibration settings.

Monthly: Lubricate moving parts (if required).

Yearly: Professional calibration.

Warning: Never use abrasive cleaners—they damage sensors.

Your choice should be based on your production capacity. If your business is in its early stages, I suggest our FT-2 series. If your business has grown to a large scale, then I suggest you choose the fully automatic series FT-8.

Please download

WhatsApp us

Simple operation interface allows you to monitor the counting process in real time

Smart Control Panel