Overview

An automatic tube filling and sealing machine is a specialized piece of equipment designed to fill empty tubes with various products and seal them efficiently. It can be gels, creams, or any other fluid. These machines are essential in manufacturing industries where products need to be packaged in tubes for consumer use.

How Does a Tube Filling Machine Work?

The machine works in simple steps:

Step1. Loading: Workers put empty tubes into the machine

Step2. Moving: The machine moves tubes to the right spot

Step3. Filling: It squirts the right amount of product into each tube

Step4. Sealing: The machine closes the tube end with heat or pressure

Step5. Finishing: Sealed tubes come out ready to use

It’s like an assembly line that works by itself!

What is an Automatic Tube Filling and Sealing Machine Used For?

These machines help many businesses:

Beauty products: Toothpaste, face cream, and hair gel.

Medicine: Skin creams and healing gels.

Food: Ketchup, mustard, and cake frosting.

Home products: Glue and repair pastes.

Care items: Hand lotion and sunscreen.

Almost any thick liquid can go into tubes this way.

What are the Different Types of These Machines?

Automatic tube filling and sealing machines come in many varieties. Each type is designed for specific needs and products. Choosing the right machine depends on what you plan to fill, what tubes you use, and how fast you need to work.

For Different Products

Not all products are the same. Some are thick, others are thin, and some are powders. Each product type needs a special machine to work well.

Thick Cream Machines

These machines handle heavy products like toothpaste, ointments, and thick lotions. They use strong pumps to push thick materials through the system. The filling heads are wider to let chunky products flow smoothly. These machines work slower but ensure accurate filling of dense products.

Runny Liquid Machines

Light liquids like shampoos, gels, and thin creams need different handling. These machines use gentle pumps that won’t create bubbles or spills. They fill faster than thick cream machines because liquids flow easily. Special sensors prevent overfilling and waste.

Powder Filling Machines

Dry products like medicine powders and cosmetic powders require special care. These machines use vibration and air pressure to move powders smoothly. They prevent dust clouds and ensure each tube gets the exact amount. Sealed chambers keep powders clean and dry during filling.

For Different Tubes

The type of tube you use affects which machine you need. Different materials require different handling methods.

Plastic Tube Machines

Most common in the market, these machines work with soft plastic tubes. They use gentle pressure to avoid crushing the tubes. The sealing heads use moderate heat that won’t melt the plastic. These machines are usually the most affordable option.

Metal Tube Machines

For aluminum or tin tubes, you need stronger machines. They apply more pressure for secure sealing. The sealing process uses higher temperatures to create permanent closures. These machines last longer because they’re built to handle tough materials.

Mixed Material Machines

Some facilities need flexibility. These versatile machines can handle both plastic and metal tubes. You can switch between tube types by adjusting settings. While more expensive, they save space and offer greater production flexibility.

For Different Speeds

Your business size and production needs determine the speed you require.

Slow Machines for Small Businesses

These machines fill 20-50 tubes per minute. Perfect for startups and small companies, they cost less to buy and maintain. They’re easier to operate and don’t need special training. Small machines also use less power and take up minimal floor space.

Fast Machines for Big Companies

High-speed machines can fill 200-500 tubes per minute. Large manufacturers need this speed to meet demand. These machines cost more but reduce labor costs over time. They include advanced features like automatic quality checking and computer controls.

The right machine type depends on your specific needs. Consider your products, tubes, and production goals when choosing. A good supplier can help you find the perfect match for your business.

What Does the Sealing Part Do?

The sealing part is the final and most crucial step in tube filling. It’s like putting a lid on a jar, but much more advanced. This component ensures your products reach customers in perfect condition.

Key Functions of the Sealing System

Keeps Air Out So Products Stay Fresh

Air is the enemy of many products. When air gets inside tubes, it can spoil creams, dry out gels, or change colors. The sealing part creates an airtight barrier that locks out oxygen. This keeps products as fresh as the day they were made.

Stops Leaks and Spills

Nobody wants messy products that leak everywhere. The sealing creates a strong closure that prevents any product from escaping. Whether tubes get squeezed, dropped, or stored sideways, a good seal keeps everything contained inside.

Keeps Germs Away From Products

Bacteria and other harmful microorganisms love to grow in open products. The sealed tube acts like a protective shield. It blocks germs from entering and contaminating your products. This is especially important for medical creams and cosmetics.

Makes Products Last Longer

Proper sealing extends shelf life significantly. Products stay stable and effective for months or even years. This reduces waste and saves money for both manufacturers and customers. Long-lasting products also build customer trust and satisfaction.

Shows If Someone Opened the Tube

A tamper-evident seal tells customers if someone has opened the product before them. This security feature is crucial for medicines and expensive cosmetics. Customers feel confident knowing their product is brand new and safe to use.

Without good sealing, products would go bad quickly. The sealing part protects your investment and your customers’ satisfaction.

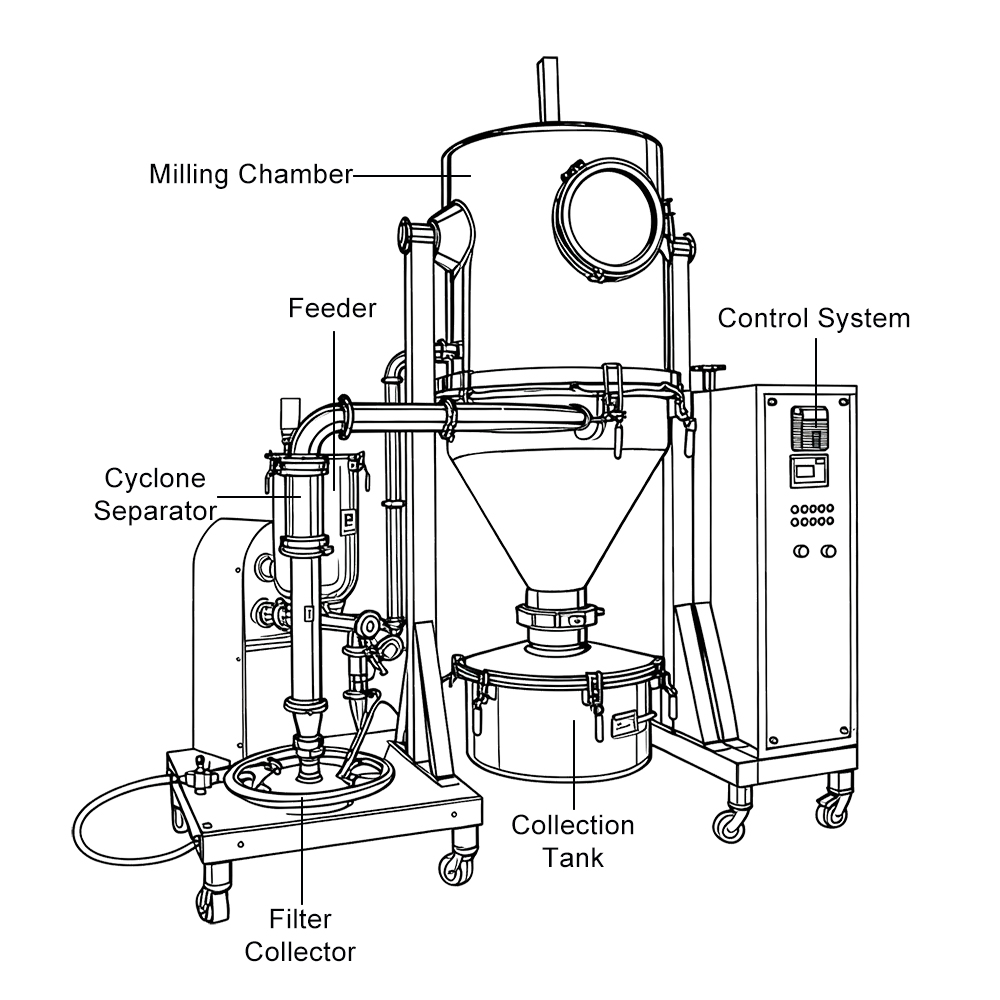

What are the Main Parts of the Automatic Tube Filling and Sealing Machine?

Every automatic tube filling and sealing machine works like a team. Each part has a specific job that helps create the final sealed product. Understanding these parts helps you operate and maintain your machine better.

1. Tube Holder: Grabs and Holds Empty Tubes

The tube holder is like mechanical hands that catch empty tubes. It positions each tube perfectly for filling. Strong grippers keep tubes steady during the entire process. Some holders can adjust to different tube sizes automatically. Without proper holding, tubes would fall or move during filling.

2. Filling Part: Puts the Right Amount of Product in Tubes

This is the heart of the machine where magic happens. Precise pumps or pistons measure exact amounts of product. Sensors ensure each tube gets the same quantity every time. The filling head moves smoothly to avoid spills or air bubbles. Speed and accuracy come together in this crucial component.

3. Sealing Part: Closes Tubes with Heat or Squeezing

The sealing part completes each tube perfectly. Heat sealers use controlled temperature to melt tube ends together. Pressure sealers squeeze tubes closed with exact force. Some machines combine both methods for extra-strong seals. This part determines how well your products will stay fresh.

4. Control Box: Buttons and Screens to Run the Machine

The control box is the machine’s brain center. Easy-to-read screens show machine status and settings. Simple buttons let operators start, stop, and adjust everything. Modern machines have touchscreens like smartphones. Error messages help solve problems quickly.

5. Product Tank: Holds the Stuff Going Into Tubes

The product tank stores your cream, gel, or liquid safely. Built-in mixers keep products smooth and even. Temperature controls maintain proper consistency. Level sensors warn when tanks need refilling. Clean, food-grade materials prevent contamination.

6. Moving Belt: Carries Tubes From Start to Finish

The conveyor belt moves tubes through each step smoothly. Variable speeds match your production needs perfectly. Guides keep tubes in straight lines without jamming. Gentle movement prevents damage to delicate tubes. Timing ensures tubes arrive at each station precisely.

7. Safety Cover: Keeps Workers Safe

Safety covers protect operators from moving parts and hot surfaces. Emergency stop buttons halt machines instantly when needed. Clear windows let workers monitor operations safely. Automatic shutoffs prevent accidents during maintenance. Safety should always be the top priority.

Each part has a special job to do. When all parts work together smoothly, you get perfectly filled and sealed tubes every time. Regular maintenance of each component ensures consistent quality and long machine life.

Benefits of Using These Machines

Why do companies love these machines?

- They work very fast

- They make fewer mistakes than people

- They keep everything clean

- They save money over time

- They make products look professional

Takeaway

Automatic tube filling and sealing machines are amazing helpers in factories. They fill tubes with creams, gels, and pastes quickly and cleanly. These machines help make the products we use every day.

If you own a business that makes tube products, these machines can help you work faster and better. They might cost money at first, but they save time and make customers happy with good products.

The next time you squeeze toothpaste or hand cream from a tube, remember the smart machine that filled it!