Pharmaceutical mixing tanks look simple from the outside, but behind those stainless-steel walls is a carefully engineered system that keeps modern drug manufacturing running. These tanks come in different types, each designed to handle specific formulations, viscosities, and production needs.

We can’t make the right decision without understanding how each type works and what it’s best suited for. And choosing the wrong one means wasted time, inconsistent batches, higher costs, and potential compliance issues, problems no manufacturer wants to face.

But don’t worry, in this guide, we’ll break down everything you need to know about pharmaceutical mixing tanks. From how they work to the different types and key features, you’ll get a clear, practical overview that helps you make smarter, faster decisions.

How Do Pharmaceutical Mixing Tanks Work?

Pharmaceutical mixing tanks are usually made from high-grade stainless steel, often SS 304 or SS 316. This helps them resist corrosion and withstand years of heavy use. While PP and PE mixing tanks are also available, they’re not resistant to strong oxidants and aromatic hydrocarbons.

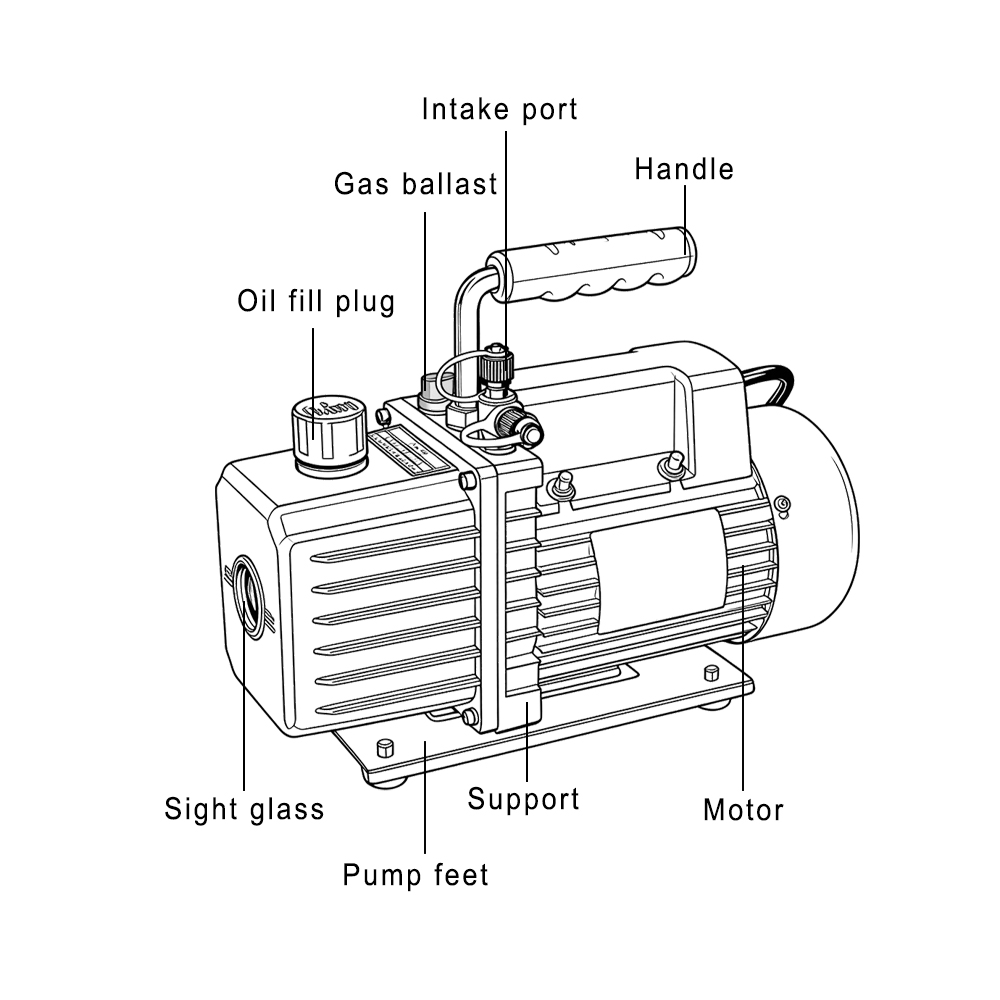

View the mixing tank working principle in an emulsifier

Inside the tank, high-speed agitators, such as propellers, paddles, or anchor blades, create centrifugal force as they rotate. These agitators are driven by electric, pneumatic, or hydraulic motors that break down ingredients through collision and shear.

The capacity of these tanks varies widely depending on production needs and material viscosity, ranging anywhere from 50 liters to 30,000 liters. Many advanced tanks are also equipped with heating or cooling jackets, enabling precise temperature control between –20°C and 150°C.

To streamline maintenance, CIP/SIP systems are often integrated, which ensures thorough cleaning and sterilization without disassembling the equipment.

Types of Pharmaceutical Mixing Tanks

Mixing tanks are an essential component of the global pharmaceutical manufacturing equipment market, which is valued at approximately $26.94 billion. These tanks come in various types, each designed to handle specific formulations, viscosities, and production requirements. Here’s a quick overview of the most common types used across the industry:

1. Stainless Steel Mixing Tank

Most pharmaceutical manufacturers use stainless steel tanks, especially SS 316 or SS 304. They’re popular for their resistance to corrosion and high durability. The smooth finish helps meet GMP and FDA standards by maintaining an aseptic environment.

Stainless steel tanks can handle a wide range of viscosities and are suitable for both liquid and semi-solid formulations.

2. Jacketed Mixing Tank

Jacketed tanks feature a surrounding jacket or channel that allows fluid or steam to flow around the vessel. This design provides precise temperature control, critical for processes such as powder dissolution. They maintain uniform heat distribution during mixing, which prevents localized overheating or cooling that could affect product stability.

3. Portable Mixing Tank

Portable mixing tanks are perfect for small-scale pharmaceutical companies with limited space. They can be moved between rooms or production lines for rapid changeovers. These tanks are commonly used in R&D labs and pilot batches where multiple formulations are produced in limited quantities.

4. Magnetic Mixing Tank

These tanks are ideal for highly corrosive substances and sterile formulations where product safety is critical. The agitator is driven by a magnetic field, eliminating the need for mechanical seals. The magnetic coupling transmits power from the motor while reducing the risk of contamination.

5. Jet Mixing Tank

Jet mixers use high-velocity liquid or gas streams to create circulation within the tank. This method reduces mechanical complexity and maintenance requirements. They are commonly utilized in gas dispersion, liquid blending, and homogenization.

6. Static Mixing Tank

Static mixers are usually installed in-line. They use internal baffles and elements to mix fluids as they pass through the mixer. Since there are no moving parts, these tanks require comparatively less maintenance.

Static mixing tanks are commonly used for dilution, blending of multiple liquids, and pH adjustments in continuous pharmaceutical processes.

7. High-Shear Mixing Tank

These mixers apply intense mechanical forces to break down particles. The shearing forces are produced by rapid rotation, turbulence, and energy dispersion. High-shear mixers are especially useful for mixing ingredients with different viscosities and densities. The most common types of high-shear mixers are in-line, batch, and rotor-stator mixers.

Benefits of Pharmaceutical Mixing Tanks

The multi-fold benefits of pharmaceutical mixing tanks have driven massive growth in their market. According to industry statistics, the industrial mixer market hit $2.88 billion in 2025. With the growing regulatory landscape in the pharmaceutical industry, this number is expected to reach $4.18 billion by 2030.

1. Enhanced Efficiency

High-quality mixing tanks significantly cut manufacturing time. The automated systems speed up production and reduce the risk of human error. Additionally, the well-designed agitators ensure thorough mixing without intensive manual labor.

With modular designs and adjustable agitators, these tanks can switch between formulations without compromising efficiency. This flexibility enhances ROI and supports scalable pharmaceutical operations.

2. Regulatory Compliance

Pharmaceutical mixing tanks are built to meet strict GMP, FDA, and EMA standards. This includes using appropriate materials, achieving smooth finishes, and validating designs. The automated CIP/SIP systems ensure thorough sanitation and prevent cross-contamination, aligning with industry regulations.

Equipment safety is further enhanced by pressure-relief valves and leak detection systems in compliance with OSHA regulations. The compliance is documented through design qualification (DQ), operational qualification (OQ), and performance qualification (PQ) protocols.

3. Thorough Mixing

Mixing tanks reduce batch variability and ensure uniform dispersion of powders, liquids, and semi-solids. This is critical for life-saving drugs where bioavailability and dose uniformity are essential. The agitation speed, temperature, and volume can be adjusted to meet production requirements.

The tanks may feature vacuum capabilities to remove air bubbles and enhance stability. Some advanced models also come with Programmable Logic Controllers (PLCs) and Human-Machine Interfaces (HMIs). These features support batch documentation and audit trails to ensure compliance with 21 CFR Part 11.

FAQs

1. What is the role of an agitator in a mixing tank?

The agitator creates controlled movement that helps dissolve ingredients, prevent settling and achieve a uniform blend.

2. Why are mixing tanks important in pharmaceutical production?

They create consistent mixtures, maintain hygiene standards and support repeatable batch quality. This helps manufacturers meet strict GMP requirements.

3. Are pharmaceutical mixing tanks customizable?

Yes. Buyers can specify volume, agitator type, heating method, control system, ports, sensors and level indicators.

Improve Your Batch Quality with Premium Pharmaceutical Equipment

Pharmaceutical mixing tanks have become an essential component of both small and large-scale facilities. While it saves resources, the real reason for their popularity is the enhanced product quality.

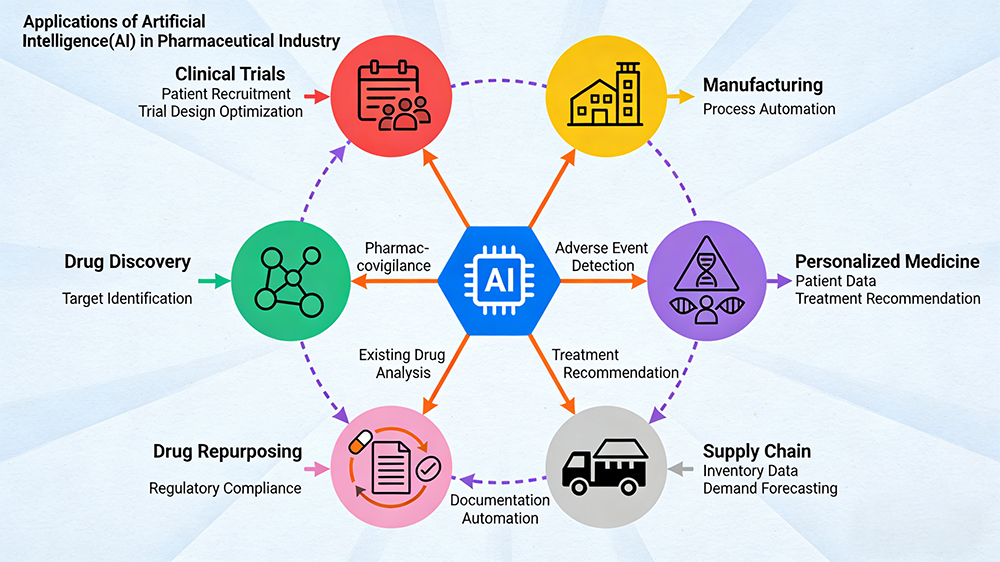

Innovative technologies such as automated mixing systems and smart tank monitoring provide actionable data and enable in-depth mixing of APIs and excipients. This shows the importance of high-quality equipment during pharmaceutical formulation and manufacturing.

However, to source these machines, you need to find a trusted supplier like Finetech. We offer a complete range of customizable pharmaceutical equipment. Whether you need process equipment or packaging machines, Finetech offers premium solutions at the best price.

Contact us now and equip your facility with the best pharmaceutical production line.