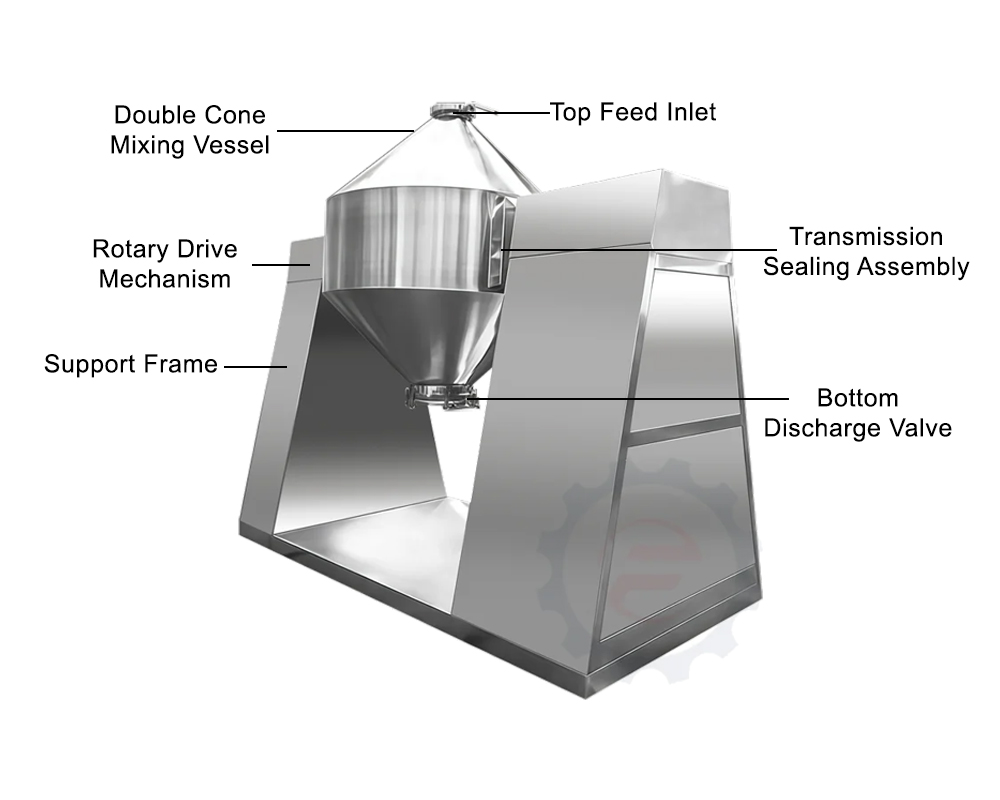

FTW Series Double Cone Mixer Pharmaceutical

The Cone Mixer consists of a frame, turnover hopper, lifting system, rotary system, and electrical control system. In a three-dimensional space in a closed hopper, powder materials are turned forcefully and diffused in a contraction effect to mix them. The mixing uniformity rate reaches 99% or more, with a residual amount of less than 0.1%, in full compliance with GMP standards. The Cone Mixer can be used to production of tablets, capsules, powders, and nutritional supplements.

Need a Custom Quote?

Or More information About this product? Contact our sales stuff today!

Key Features

Technical Data

Machine Details

FAQ

Application Powder Types

1. The machine has fixed double columns, an automatic feeding system, and a mechatronic mixing system. It is easy to operate and set running program.

2. This mixer improved efficiency and avoids cross-contamination.

3. The entire mixing process is completed in a closed barrel, with a mixing uniformity rate over 99%, a volume loading system reaches 80%, and a 316L inner wall, 304 body.

4. The Cone Mixer is compatible with volume ranging from 5L to 2,000L and is especially designed for mixing materials of poor fluidity.

5. High mixing efficiency, low energy consumption, easy operation, cleaning, and maintenance.

6. PLC human-machine interface automatic control system with hierarchical management authority, which meets the tracking and traceability requirements of certification processes such as FDA/GMP.

7. Application: Active Pharmaceutical Ingredients (APIs), Combining spices and seasonings, Blending detergent powders and cleaning compounds, Powdered Water Soluble Fertilizer.

| Model | FTW-50 | FTW-100 | FTW-150 | FTW-200 | FTW-300 | FTW-500 | FTW-1000 |

| Total Volume (L) | 50 | 100 | 150 | 200 | 300 | 500 | 1000 |

| Maximum Loading Capacity (L) | 25 | 50 | 75 | 100 | 150 | 350 | 700 |

| Maximum Loading Weight (kg) | 25 | 50 | 75 | 100 | 150 | 210 | 420 |

| Motor Power (kW) | 0.75 | 0.75 | 1.1 | 1.1 | 1.5 | 2.2 | 4 |

A Double Cone Mixer is a gentle, tumble-type blender used for dry powder and granule mixing. It consists of two conical sections welded to a central cylindrical shaft. The entire vessel rotates on its horizontal axis, causing the material to be lifted and then tumbled back on itself in a continuous, cascading motion. This low-shear, diffusive mixing action ensures a uniform blend without damaging particle structures.

It is ideal for pharmaceuticals due to its:

Gentle Blending: Prevents attrition or heat generation of sensitive Active Pharmaceutical Ingredients (APIs) and granules.

Uniform Homogeneity: Achieves excellent blend uniformity for consistent dosage.

Minimal Segregation: The gentle tumbling action minimizes the separation (demixing) of different particle sizes or densities.

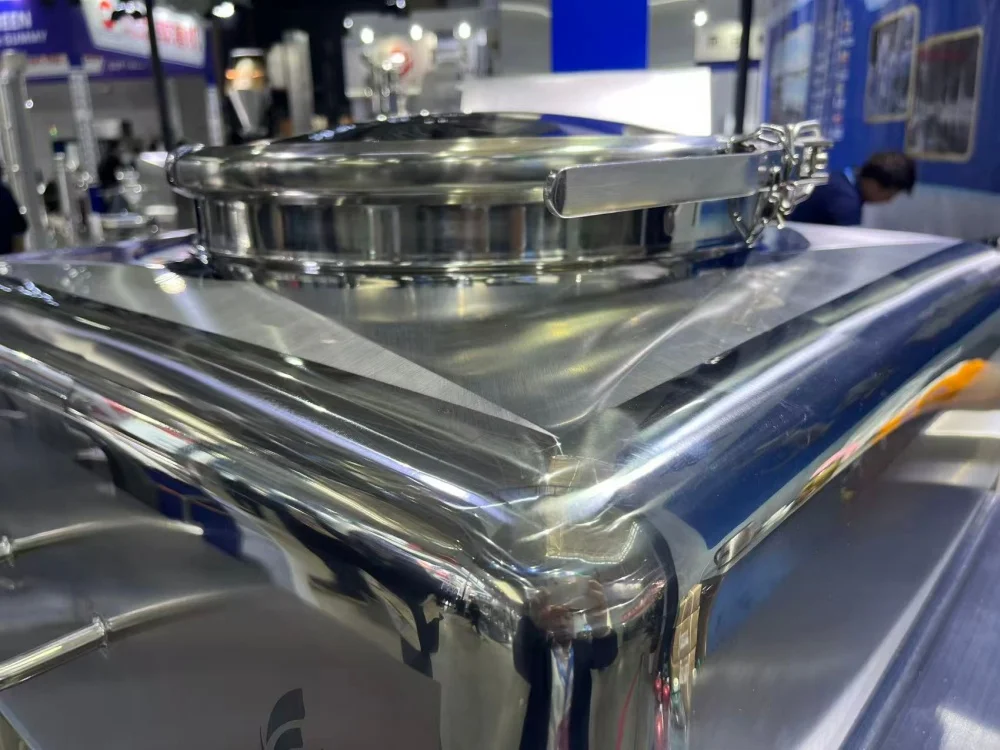

cGMP Compliance: Designed with polished stainless steel (304 or 316L), no dead zones, and features for easy cleaning and validation.

Versatility: Suitable for blending APIs, excipients, dry powders, and granules.

Sanitary Construction: Mirror-finished internal surfaces (Ra ≤ 0.4 µm).

Sealed System: Glandless seals or advanced mechanical seals to prevent lubrication contamination and product leakage.

Easy Cleaning: Options for Clean-In-Place (CIP) systems, rapid discharge valves, and easy disassembly.

Smooth Surfaces: Internally welded joints, polished to prevent material adherence and microbial growth.

Documentation: Support for DQ, IQ, OQ, PQ protocols and 3.1 material certificates.

Uniformity is validated through a Performance Qualification (PQ) protocol using tracer studies (e.g., a colored or soluble tracer like Riboflavin). Samples are taken from multiple predetermined locations after a set number of rotations. The content uniformity is analyzed via HPLC or UV spectroscopy to prove the mixer achieves a homogenous blend (typically with an RSD of ≤ 5%).

The optimal working volume is typically 50-60% of the total gross volume. Under-filling (below 30%) reduces mixing efficiency, while over-filling (above 70%) impedes the cascading tumbling action, leading to poor blending.

The optimal working volume is typically 50-60% of the total gross volume. Under-filling (below 30%) reduces mixing efficiency, while over-filling (above 70%) impedes the cascading tumbling action, leading to poor blending.

Yes. Modified designs include:

Containment Systems: Split butterfly valves, sealed loading/unloading ports.

Potent Compound Handling: Integrated glove boxes, wash-in-place (WIP) systems, and negative pressure operation to protect operators and the environment (OEB levels 4-5).

Not for Wet Mixing: Designed for dry solids only.

Not for Cohesive Powders: Extremely sticky or cohesive materials may not blend effectively without additional agitators.

Density/Size Differences: Large differences in particle size or density can still lead to segregation; formulation science is key.

Regular inspection of seals and bearings.

Verification of drive belt tension and motor alignment.

Periodic re-calibration of speed sensors.

Post-campaign cleaning and visual inspection per SOPs.

1. Pharmaceutical & Healthcare

Medicine manufacturing: Mixing active drugs with fillers, binders, and lubricants for tablets/capsules

Nutritional supplements: Protein powders, vitamin blends, meal replacements

Medical products: Antibiotic powders, contrast agents, surgical powders

Dental products: Tooth powder formulations

2. Food & Beverage

Instant products: Soup mixes, drink powders (coffee, tea, chocolate), dessert mixes

Spices & seasonings: Blended spices, gravy powders, seasoning packets

Bakery mixes: Cake mixes, bread premixes, icing sugar blends

Nutritional products: Infant formula, sports nutrition, fortified foods

3. Chemicals & Industrial

Detergents & cleaners: Laundry powder, dishwasher detergent, industrial cleaners

Construction materials: Dry mortar, tile adhesives, cement additives

Plastics & polymers: Color masterbatches, filler compounds, polymer blends

Explosives & pyrotechnics: Firework compositions (safely engineered)

Agriculture: Fertilizer blends, pesticide powders, seed coatings

4. Cosmetics & Personal Care

Makeup: Foundation powders, eyeshadows, blush

Skincare: Talcum powder, medicated body powders

Cosmetic additives: Pigment blends, glitter mixtures

5. Advanced Materials

Metal powders: Alloy preparations for 3D printing (additive manufacturing)

Ceramics: Technical ceramic formulations

Batteries: Electrode material blends for lithium-ion batteries

Electronics: Conductive paste powders, solder blends