Ever popped a pill out of its pack and wondered, “Why this kind of packaging?” You’re definitely not alone. The debate between blister packs vs strip packs has been ongoing for quite some time.

But it’s time to settle it once and for all.

Whether you’re in pharmaceuticals or the supply chain, understanding the difference between blister and strip packs can help you make smarter choices.

Let’s break it down in the simplest way possible.

What Is a Blister Pack?

A blister pack is a type of packaging where pills, capsules, or tablets are sealed in small, individual pockets made from plastic or aluminum. Each dose sits inside a bubble (the “blister”), usually covered by a foil or plastic backing that you peel off or press through.

This kind of packaging is a smart way to keep medicine safe, fresh, and easy to use. Blister packs are most commonly used in the pharmaceutical industry, but are also common for dietary supplements, chewing gum, batteries, and even consumer electronics accessories.

Key Benefits of Blister Packs

Here are a few benefits of using blister packs:

- Protects Against Moisture: Each dose is sealed in its own compartment, shielding it from moisture and other external elements until it’s opened.

- Improves Dose Tracking: Blister packs make it easy for patients to keep track of their medication. With separate compartments for each dose, it’s clear whether you’ve taken your pill or not.

- Safer for Children: Some blister packs are also made child-resistant, which makes it harder for little hands to access the tablets without help.

What Is a Strip Pack?

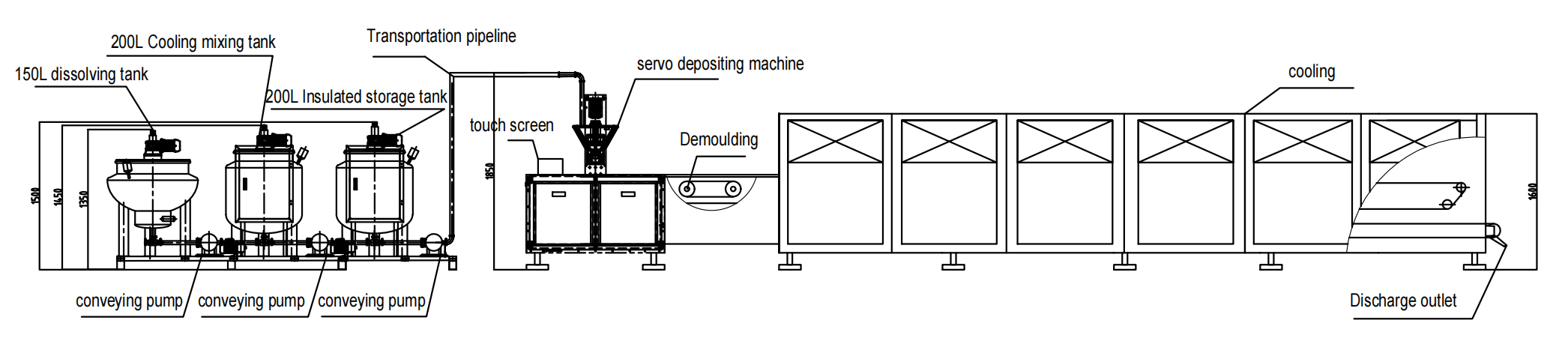

Strip packs are using strip packing machine made it, It is another pharmaceutical packaging type, but unlike blister packs, they don’t form individual plastic bubbles. Instead, they seal tablets or capsules between two layers of aluminum foil. This creates a flat, strip-like pouch that protects each dose.

These packs are popular for both prescription medications and over-the-counter drugs, especially those that need extra protection from air and moisture.

Key Benefits of Strip Packs

The key benefits of strip packs include:

- Protection from Light and Moisture: Strip packs offer an excellent barrier against the three biggest threats to drug stability: light, oxygen, and humidity. This makes strip packs ideal for highly sensitive formulations.

- Better for Hot Climates: Strip packs are usually the preferred packaging choice in regions with high humidity and temperature. The tight aluminum seal prevents environmental exposure, helping maintain drug quality.

- Ideal for Precise Dosing: Like blister packs, strip packs support unit-dose packaging, which means each pill is individually sealed.

Blister Pack vs Strip Pack: A Feature-by-Feature Comparison

The blister pack vs strip pack debate ends today. Here’s a feature-by-feature breakdown:

1. Material and Barrier Protection

Blister packs are usually made with a plastic cavity (PVC or PVDC) sealed with aluminum foil. This provides moderate moisture and air protection, but isn’t 100% impermeable.

On the other hand, strip packs are made from two layers of aluminum foil. This offers a superior barrier against light, moisture, and oxygen, making it ideal for sensitive products.

| Feature | Blister Pack | Strip Pack |

| Material Used | PVC + Aluminum Foil | Aluminum + Aluminum |

| Light Barrier | Moderate | Excellent |

| Moisture / Oxygen Barrier | Good | Excellent |

| Best For | General medications and supplements. | Heat/humidity-sensitive medications. |

Verdict: Strip packs win on barrier protection when it comes to tropical or high-humidity regions.

2. Manufacturing Process and Cost

Strip packs are manufactured using simpler, low-heat or no-heat sealing processes, which come at a very low cost. Even though they are slower than blister pack lines, they are more economical for small to medium batches.

Alternatively, the blister packs require thermoforming or cold-forming machines, which are more complex and expensive. These machines offer high-speed output but require more energy and maintenance.

Verdict: Strip packs are more cost-efficient for simpler needs, while blister packs are ideal for high-volume automated production.

3. Patient Convenience

When it comes to patient convenience, blister packs have a clear advantage. They come in perforated units, allowing patients to tear off one tablet at a time with ease. Strip packs, unfortunately, aren’t as user-friendly. They can be harder to open and lack visibility of the pills until the packaging is torn.

However, strip packs are more compact, making them easier to store and transport, particularly in bulk packaging or limited shelf spaces.

Verdict: Blister packs win in this category because of their ease of use and visibility for patients.

4. Storage and Logistics

The pharmaceutical industry is rapidly growing, with projections estimating it will reach $3,033 billion by 2034. This growth means higher drug production volumes, which increases the demand for more efficient storage solutions worldwide.

This is where the minor difference in blister pack vs strip pack can become the game-changer. Blister packs tend to be bulkier due to their rigid cavities and backing materials, taking up more space during storage and shipment.

In contrast, strip packs feature a slim, flat design that makes them easier to store, stack, and transport, offering a logistical edge in high-volume operations.

Verdict: Strip packs are better for space-saving, but if you’re a retailer, blister packs would be the better option.

5. Shelf Life and Stability

Blister packs are great for stable formulations as they have a moisture barrier. They work well for most tablets and capsules, but may not be sufficient for extremely sensitive compounds.

Strip packs, with their aluminum-aluminum construction, offer a much higher level of barrier protection. This makes them suitable for drugs that are sensitive to moisture and light, such as antibiotics or biologics.

Verdict: Strip packs generally offer longer shelf life due to better environmental sealing.

6. Speed of Packaging

Blister machines can be fast and highly automated. However, it takes time to set up, and the machine costs are typically higher.

Strip packaging machines, in comparison, are simpler and used in lower-cost applications. They’re useful for low-cost drugs and large-volume batches.

Verdict: Blister packs are better for high-end, branded drugs, while strip packs suit mass production and generics.

When Should You Use a Blister Pack vs Strip Pack?

Choosing between a blister pack and a strip pack depends on several factors, such as drug sensitivity, climate, logistics, and patient needs. There’s no one-size-fits-all solution. Instead, each format fits a different use case.

Let’s explore when to choose one over the other based on real-world conditions and product requirements.

When to Use a Blister Pack

You should use a blister pack when:

1. Patient Compliance and Convenience Matter

If the medication is taken daily or in a specific order, blister packs are ideal. The perforated design allows patients to track their doses easily. This is helpful for elderly patients, chronic illness treatments, or pediatric care.

2. Tamper Evidence is Legally Required

For over-the-counter drugs, blister packs are also required by regulatory bodies like the FDA because they make tampering easy to detect. If safety and trust are top priorities, go blister.

3. A Premium Feel is Needed

For high-end supplements or branded medications, blister packs give a more polished, high-quality look. The packaging itself can become a marketing advantage.

When to Use a Strip Pack

Strip pack should be used when:

1. The Drug is Highly Sensitive

Strip packs, the aluminum-aluminum ones, are the gold standard in barrier protection. If you’re packaging antibiotics, probiotics, or heat-sensitive drugs, this is the safer choice.

2. Compact Packaging is Needed

Strip packs are slimmer and easier to stack or store in bulk. Hospitals and clinics that need to keep large volumes on hand choose strips for space efficiency.

3. Cost and Speed are Major Concerns

For generic or government-subsidized medications, strip packs can be produced faster and at a lower cost. The machinery is simpler, and the materials used are efficient for large-scale runs.

Smart Packaging Starts with Clarity

When it comes to pharmaceutical packaging, there’s no one-size-fits-all solution. When you choose blister pack vs strip pack, it depends on the drug’s stability, cost, climate, and regulatory needs.

Blister packs offer better visibility and patient tracking. Meanwhile, strip packs provide excellent protection in challenging environments.

If you’re still deciding between the two, remember that each format solves a different problem. Choose based on what your product and your end users need most.

FAQs

1. Which type of packaging is better for hot and humid climates?

Strip packs are the preferred choice in hot, humid environments due to their excellent barrier properties. They use aluminum on both sides, which helps protect moisture-sensitive drugs from degradation. This makes them ideal for countries with tropical climates or where pharmaceutical cold chains are not consistently reliable.

2. Is a blister pack easier to open than a strip pack?

Yes, blister packs are easier to open because users can simply push the tablet through the foil backing. This is helpful for elderly patients or those with limited hand strength. In contrast, strip packs often require tearing along pre-cut lines, which may be more difficult without tools or scissors.

3. Can blister and strip packs be recycled?

Traditional blister and strip packs are not easily recyclable through regular household bins due to their mixed-material construction. Some countries are also exploring mono-material alternatives that would make pharmaceutical packaging easier to recycle in the future.

Recommend Readings:

6 Common Blister Packaging Types in the Pharmaceutical Industry