Making tablets is a complex process. It needs many special machines. Each machine has a specific job. Together, they create the medicines we take every day. Let’s explore the key equipment used in tablet production lines. This guide will help you understand how tablets are made from start to finish.

The Tablet Making Journey

Tablet production follows a clear path. First, raw materials get mixed. Then they become granules. Next, machines compress them into tablets. Finally, the tablets get coated and packaged.

Each step needs different equipment. The right machines ensure quality tablets every time.

Mixing Equipment: Where It All Begins

Mixing is the first step in tablet production. Different machines handle this important task.

Double Cone Blender

The double cone blender mixes dry powders perfectly. It has a cone shape that tumbles materials gently. This creates an even mixture without damaging delicate ingredients.

These blenders work well for basic mixing jobs. They’re reliable and easy to use. Many factories start their production with these machines.

Rapid Mixer Granulator (RMG)

The RMG is a powerful machine. It can mix dry ingredients and make granules too. This saves time and space in production.

The machine has spinning blades that mix materials fast. It can also add liquids to create wet granules. This versatility makes it very popular.

V-Blender

V-blenders have a V-shape design. They mix powders by tumbling action. The unique shape ensures thorough mixing.

These machines work great for heat-sensitive materials. They mix gently without creating heat. This protects delicate ingredients.

Other Mixing Options

Factories also use pneumatic mixers, diffusion mixers, and convective mixers. Each type serves different needs. Some work better for specific materials or batch sizes.

Granulation Equipment: Creating the Right Size

Granulation makes powder particles stick together. This step is crucial for good tablets.

Horizontal Granulator

This machine makes uniform granules. It uses a horizontal mixing action. The result is consistent particle sizes.

Uniform granules lead to better tablets. They compress more evenly. This reduces defects and waste.

Drying Equipment: Removing Moisture

Wet granules need drying before compression. Too much moisture causes problems.

Fluid Bed Dryer

This is the most common drying machine. It uses hot air to dry granules. The air makes granules float and tumble. This movement ensures even drying. The machine controls temperature carefully. This protects the active ingredients.

Tray Dryer

Tray dryers work differently. They dry materials in trays. Hot air circulates around the trays. These machines handle larger batches. They’re good for materials that can’t be fluidized.

Tableting: The Heart of Production

Tableting machines compress granules into solid tablets. This is where the magic happens.

Single Punch Tablet Press

These machines make one tablet at a time. They’re perfect for small batches or research work. The machine uses one set of punches and dies. It’s simple to operate and maintain. Many companies use them for testing new formulas.

Rotary Tablet Press

For large production, rotary presses work better. They have multiple punch stations. This means many tablets form at once. These machines can make thousands of tablets per hour. They’re efficient and reliable for commercial production.

Dies and Punches

These parts shape the tablets. Dies form the tablet outline. Punches compress the material. Different shapes and sizes are possible. Round, oval, and specialty shapes all work. The choice depends on the product needs.

Coating Equipment: Adding Protection

Many tablets need coatings. Coatings can mask taste, control release, or improve appearance.

Tablet Coating Machine

These machines spray coating material onto tablets. The tablets tumble while coating sprays on. Hot air dries the coating quickly. This creates a smooth, even surface. The process repeats until the coating is complete.

Packaging Equipment: Ready for Delivery

Finished tablets need proper packaging. Different machines handle various package types.

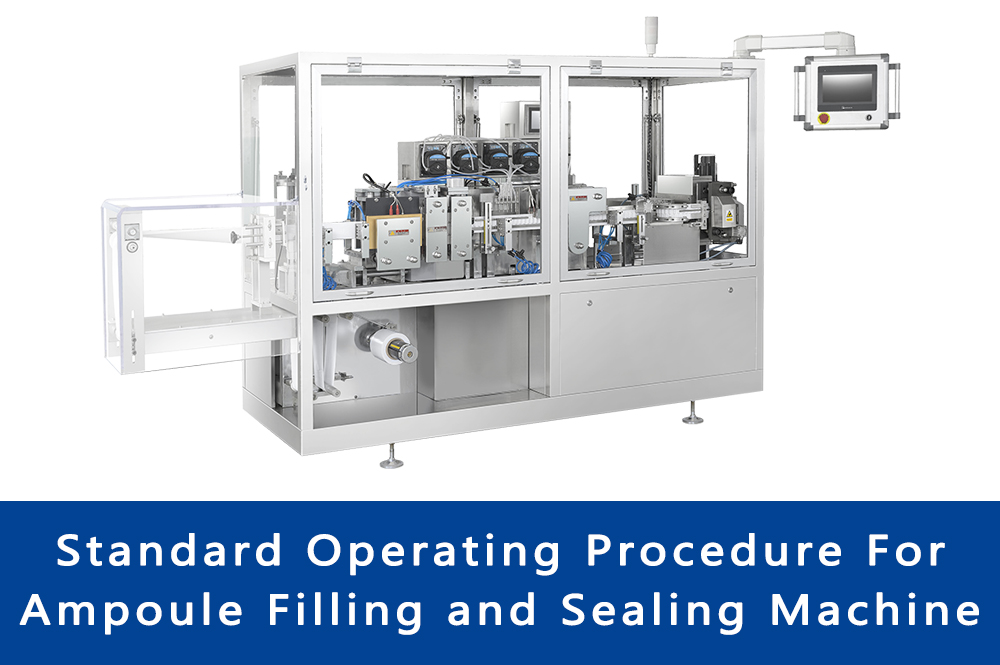

Blister Pack Machine

These machines create individual tablet pockets. Each tablet sits in its own space. A foil top seals everything. Blister packs protect tablets well. They also make dosing easy for patients.

Bottle Filling Machine

Some tablets go into bottles. These machines count and fill bottles automatically. They can handle different bottle sizes. Speed and accuracy are key features.

Quality Control Equipment

Quality matters in tablet production. Special equipment helps maintain standards.

Sifter

Sifters separate particles by size. Only the right-sized granules make good tablets. These machines use screens or vibration. They remove oversized or undersized particles.

Milling Equipment

Sometimes particles are too big. Mills reduce particle size. Both wet and dry mills exist. The right particle size improves tablet quality. It also helps with mixing and compression.

Metal Detector

Safety is crucial in medicine. Metal detectors find any metal contamination. These machines check tablets before packaging. They reject any contaminated products automatically.

Inspection Equipment

Inspection belts let workers examine tablets. They can spot defects like cracks or chips. Good inspection prevents bad tablets from reaching patients.

Environmental Control Equipment

The production environment matters too. Special equipment maintains proper conditions.

Dust Extractor

Tablet making creates dust. Dust extractors remove it from the air. Clean air protects workers and products. It also prevents cross-contamination.

Dehumidifier

Humidity affects tablet quality. Dehumidifiers control moisture levels. The right humidity prevents problems during production. It also protects finished products.

Laminar Flow Unit

These units provide ultra-clean air. They’re essential for sterile products. Clean air flows in one direction. This prevents contamination during sensitive steps.

Conclusion

Tablet production needs many specialized machines. Each one has an important role. Together, they create safe, effective medicines. Understanding this equipment helps appreciate the complexity of tablet making. It also shows why quality control matters so much. Modern tablet production combines technology and precision. The result is the reliable medicines we depend on every day.

Recommend Readings:

List Of Equipment Used in Tablet Manufacturing.

How Are Medicine Tablets Made? A Simple Guide to the Manufacturing Process.