Cellophane Packaging Machines

Cellophane Packaging Machine is an automated system designed to wrap products in transparent cellulose film (cellophane) or other flexible films like polypropylene (PP) or polyethylene (PE).

Discover Our Cellophane Wrapping Machines

Enhance product appeal and protection with our automatic cellophane packaging machines. Perfect for candy, baked goods, cosmetics, and gifts.

Packaging material: BOPP, PVC

Packaging speed): 40-90 packs per minute

Packaging material: BOPP, PVC

Packaging speed: 30-70 packs per minute

Packaging material: BOPP, PVC, POF, PE

Packaging Speed: 35-80 packs per minute

Specification

| Model | FTBT-290 | FTBT-300 | FTBT-480 | FTBTA-450 |

|---|---|---|---|---|

| Power supply and total power | 220V 50Hz 5kw | 220V 50Hz 6kw | 220V 50Hz 6kw | 220V50Hz 1.3Kw |

| Packaging Material | BOPP, PVC | BOPP, PVC | BOPP, PVC | BOPP, PVC |

| Packaging speed (packs / minute) | 30~70 | 30~60 | 40~90 | 35~85 |

| Equipment weight (kg) | 350 | 430 | 500 | 550 |

| Overall dimensions(Length * Width * Height) | 1500*850*1700(mm) | 1870*900*1700(mm) | 2200*1870*1700(mm) | 180*800*1600(mm) |

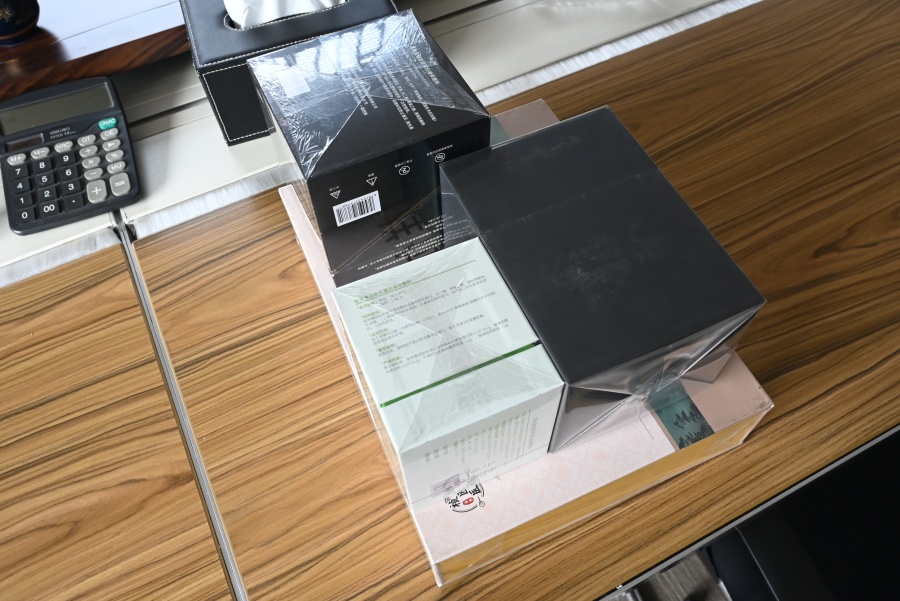

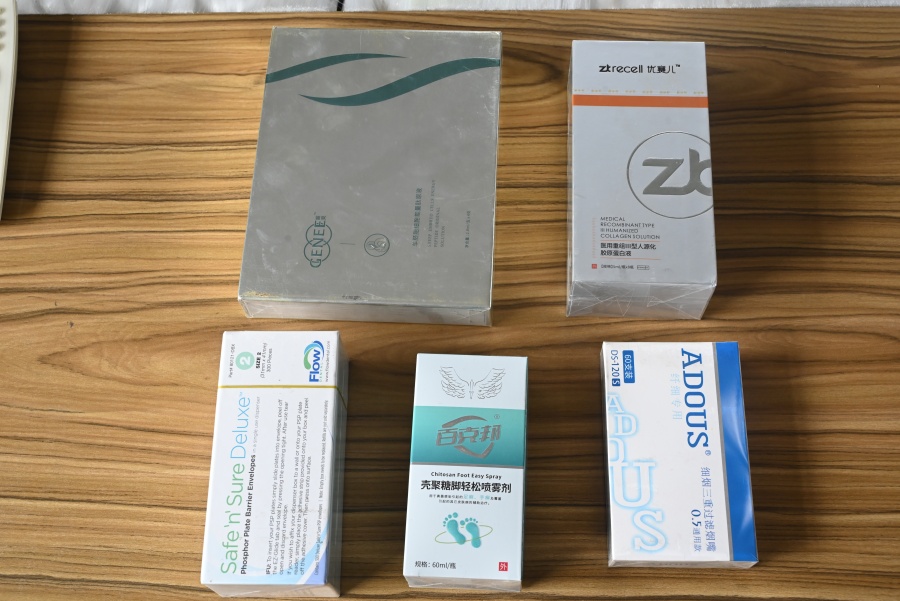

Sample Uses

Want to learn more?

Key Components of Cellophane Packing Machine

Neatly folds the cellophane around the product.

Folding & Wrapping Unit

Transports products into the wrapping zone.

Product Conveyor

Adjusts speed, film length, and sealing temperature.

Control Panel (HMI/PLC-Based)Cellophane Packaging Machine Working Steps

- Step 1. Product Feeding: Products are fed via a conveyor belt or robotic arm.

- Step 2. Film Cutting: A cutting mechanism (blade, hot wire, or ultrasonic cutter) trims the film precisely.

- Step 3. Wrapping the Product: Film covers the product from top/bottom or sides, with excess folded.

- Step 4. Sealing the Edges: Heated bars press and melt the film edges (for PVC or polypropylene films).

- Step 5. Shrinking:For shrink wrap machines, the product passes through a heat tunnel, where hot air (or infrared) shrinks the film tightly around the product.

- Step 6. Cooling & Ejection: cools briefly to harden the seal and conveyor belt discharges the wrapped product for collection or further packaging.

Related Videos

FTBT-300 Cellophane Wrapping Machine Running Video

FTBT 480 Cellophane Wrapping Machine Running Video

Shrink Wrapping Machine Running Video

FAQ

POV, PVC, PE

Clean sealing bars regularly to prevent residue buildup.

Inspect heating elements for wear.

Lubricate moving parts (if applicable).

Replace worn-out components (wires, belts, etc.).

Yes, we can customize both molds and film systems to meet your needs. For more details, you can visit our custom services page.

Cellophane is stiff, non-stretchy, and is often used for decorative wrapping (e.g., gift baskets, perfume boxes).

Shrink wrap (POF, PVC, PE) stretches and tightens when heated; it is used for secure packaging.

Gift baskets & hampers

Flowers & bouquets

Candies, chocolates, baked goods

Cosmetics & luxury items

Books & stationery

Finetech focuses on sustainable development, so we use wood pulp and biodegradable packaging materials as our first choice.

We have semi-automatic wrapping machine options with manual film configuration.

Check here:

These machines are versatile and commonly used for:

Food items: Chocolates, candies, cookies, snack bars, baked goods

Gifts & stationery: Greeting cards, flower bouquets, gift baskets

Cosmetics: Soaps, bath bombs, candles, beauty products

Pharmaceuticals: Overwrapping of boxes for moisture barrier

Retail items: Small consumer goods, merchandise, promotional items

While called “cellophane” machines, most handle multiple film types:

Traditional cellophane (biodegradable, high clarity)

BOPP (biaxially oriented polypropylene – moisture-resistant, cost-effective)

Polyethylene (excellent seal strength, good stretch)

Shrink films (PVC, PETG, polyolefin)

Metallized or printed films for branding

Flow wrapping (horizontal form-fill-seal): Film wraps completely around the product, with seals on the back and ends. Used for individual items like candy bars.

Overwrapping: Pre-formed items (like boxes) are wrapped in a sleeve of film, with folded or sealed ends. Common for gift boxes and bundled products.

Common causes and fixes:

Wrinkles: Adjust film tension or forming box alignment

Weak seals: Increase temperature, pressure, or dwell time

Film breaks: Check for sharp edges on product or guides; reduce tension

Misaligned packages: Adjust product infeed timing or positioning

ROI typically ranges from 6 to 24 months, depending on:

Labor savings (replacing 2–6 manual wrappers)

Increased production output

Reduced material waste

Improved packaging quality leading to fewer returns

Traditional cellophane is biodegradable and compostable (made from wood pulp), but often has a plastic coating. For eco-friendly options, look for:

Uncoated cellophane

Certified compostable films

Bio-based polymers (like PLA)

Smoothly sends the film to the wrapping area.

Film Unwinding & Feeding System