ZP31/29/27 Double-Sided Rotary Tablet Press Machine

A Double-Sided Rotary Tablet Press machine is an advanced, high-capacity tablet manufacturing machine that features two independent compression mechanisms on a single turret, allowing it to produce tablets from both sides of the rotating turret simultaneously.

Need a Custom Quote?

Or More information About this product? Contact our sales stuff today!

Key Features

Technical Data

Machine Details

FAQ

Application

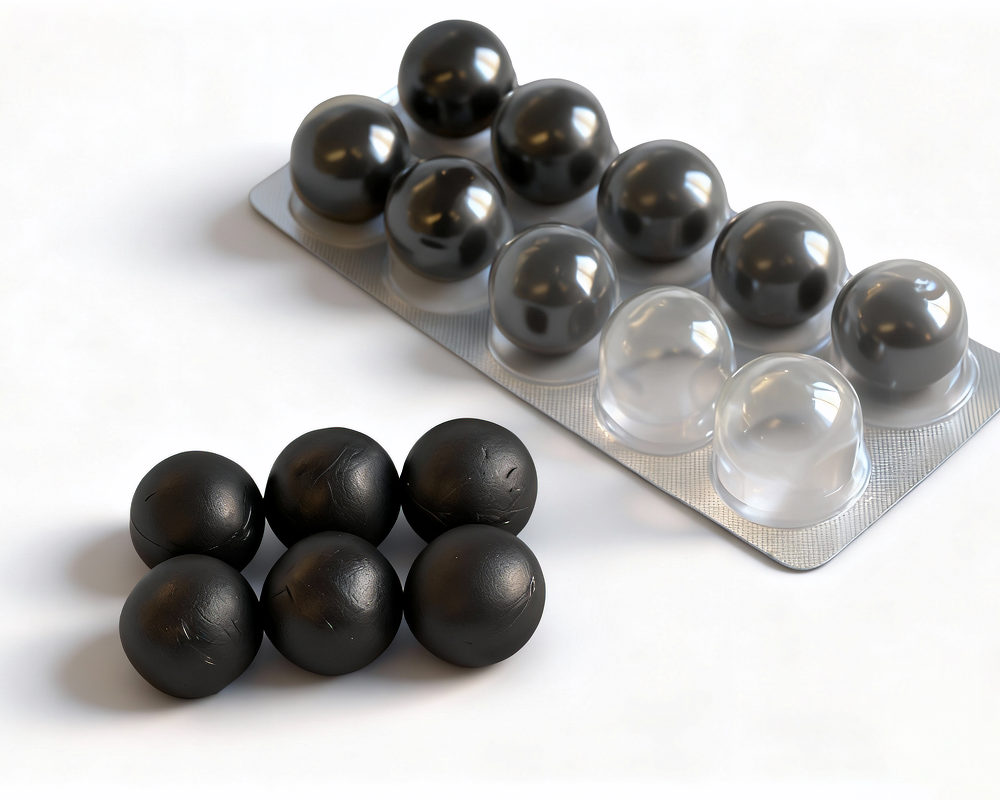

Double-press type with high productivity, suitable for making large-sized tablets.

Made of stainless steel, the housing is fully closed. The surface of the rotary turretis covered with a hardened layer so that the turret surface is wear resistant.The machine conforms to GMP requirment.

Adopt transparent windows, tableting state can be observed clearly. The windows can be opened,cleaning and maintenance are easy.

The machine can stop automatically in case of overpressure.

Speed adjustable, operation simple and reliable.

| Model | ZP31 | ZP29 | ZP27 |

| Number of Stations: | 31 | 29 | 27 |

| Max Main Pressure(KN): | 100 | ||

| Max Tablet Diameter(mm): | 25 | ||

| Max Filling Depth(mm): | 15 | ||

| Max Tablet Thickness(mm): | 6 | ||

| Max Turret Speed(r/min): | 30 | ||

| Max Production Capacity(pcs/n): | 111600 | 104400 | 97200 |

| Motor Power(kw): | 5.5 | ||

| Overall Size(mm): | 1140×1000×1650 | ||

| Machine Weight(kg): | 1850 | ||

It’s a high-speed tablet compression machine with two compression stations — upper and lower punches compress powder simultaneously from both sides, allowing for pre-compression and main compression in one rotation cycle. This enables higher production rates, better tablet uniformity, and the ability to make multi-layer or coated tablets in some designs.

Single-sided press: One compression station, lower punch is stationary during compression, slower output.

Double-sided press: Two compression stations (pre-compression and main compression), both upper and lower punches move, higher output, better de-aeration, suitable for difficult powders.

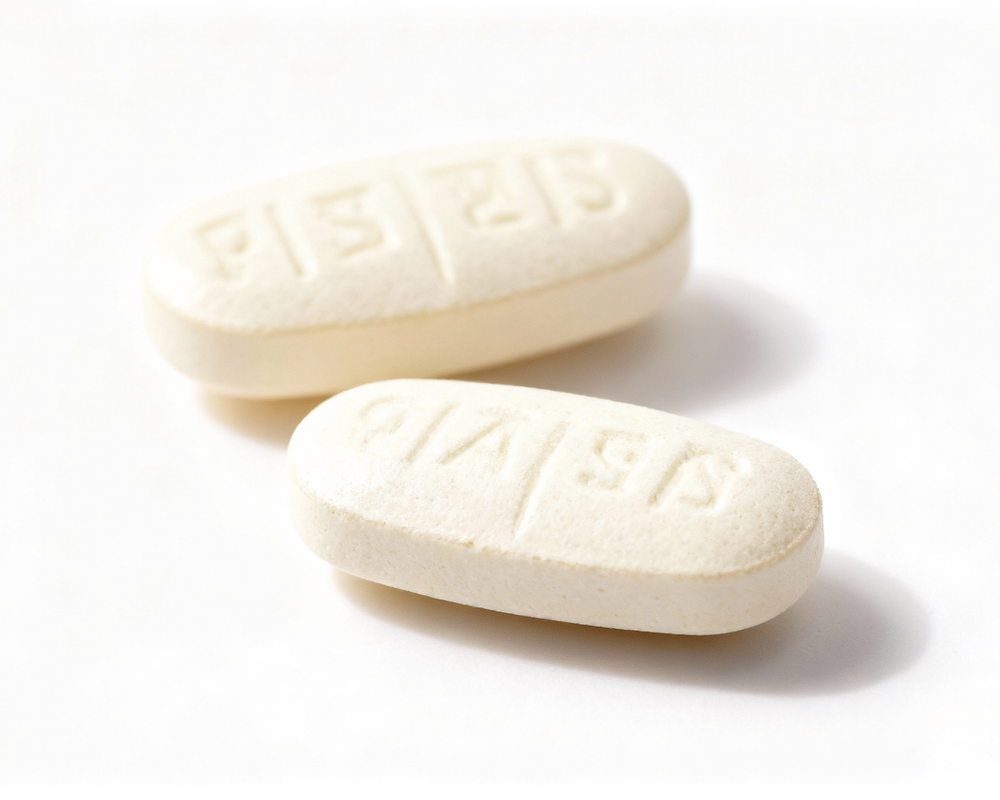

High-volume production of pharmaceutical tablets

Nutritional supplements

Industrial products (e.g., detergents, catalysts)

Multi-layer tablets (with dual-feed systems)

Chewable, effervescent, and high-strength tablets

Turret speed (RPM) and number of stations

Pressure capacity (tons)

Pre-compression and main compression adjustability

Feeding system (single, dual, or multiple feeders)

Force monitoring system (for weight/hardness control)

Tooling compatibility (B, D, BB, etc.)

Safety features: guards, interlocks, emergency stop

Cleaning & changeover ease (CIP/SIP if required)

Data recording & compliance (GMP, 21 CFR Part 11)

Lower punch filling depth adjustment (manual or automated)

Weight control system using compression force monitoring: measures force on each station and adjusts fill depth accordingly for constant weight.

Maintain uniform granule size & moisture content

Optimize compression force and dwell time

Keep tooling in good condition (no worn or damaged punches/dies)

Regularly calibrate weight control system

Keep machine clean and well-lubricated

Yes, with proper feeder design (e.g., force feeder) and pre-compression to remove air. May require formulation optimization (glidants/lubricants).

Standard B, D, or BB tooling (depending on tablet size). Punches can be flat, concave, bevel-edged, or shaped for logos. Quality tooling (e.g., carbide-tipped) extends life for abrasive products.

Ranges from 20,000 to over 1,000,000 tablets/hour depending on number of stations (e.g., 35‑75 stations) and turret RPM.

Yes, with dual or triple feeding systems and layered compression settings. Requires precise layer weight control and sequential filling.