7 Types of Blender Used in the Pharmaceutical Industry

Blending is one of the most crucial steps in manufacturing. It ensures that every dose of medicine has the right

High-shear powder mixer, ribbon blender, and conical mixer solutions. Designed for efficient industrial powder mixing, blending dry ingredients, and ensuring batch uniformity. From lab to full production scale.

Powder mixing machines are used to combine two flowable dry materials or mix a powder into a liquid. They use mechanical force and gravity to do that. Here are some of our top-quality and certified powder mixing machines:

Design Volume (L): 100 to 1000

Capacity (L): 20 to 500

Power (kW): 1.5 to 3

Outlet Height (mm): 550 to 700

Speed (rpm): 12 to 15

Inlet Size (mm): 220 × 100 to 270 × 150

Weight (kg): 200 to 900

Volume (L): 300 to 2000

Output (Kg/Tank): 150 to 1000

Rotating Motor (KW): 1.5 to 5.5

Mixing Motor (KW): 1.5 to 5.5

Mixing Time (mins.): 0 to 30

Total Power Energy (Kw): 0.25-0.75

Mixing Rotatory Speed (rpm): 20-35

Capacity (L): 2-30

Weight(Kg): 19

Overal Size(mm): 400*330*420

Total Power Energy (Kw): 3 to 22

Mixing Rotatory Speed (rpm): 46

Barrel Volume (mm): 680-2000 x 420-1068 x 490-534

Radius of Barrel (mm): 210 to 534

Effective Volume (L): 100 to 2000

Power Supply: 3 Phase 208-415v 50/60 HZ

Max Loading Volume (L): 1000

Speed (rpm): 3 to 11

Weight (kg): 4000

Voltage: 400V, 3 phases, 50Hz

Max Loading Weight (kg): 400/batch

Bin Volume (f): 1200

Rotating Motor Power (Kw): 7.5

Net Load(Kg): 200-1500

Mixing Rotatory Speed(rpm): 3 to 15

Lifiting Height(mm): 750-850

Total Power Energy (Kw): 5.5-15

Weight(Kg): 1700-3500

Net Load(Kg): 50-200

Mixing Rotatory Speed(rpm): 3 to 15

Stirring Speed(rpm): 50-150

Total Power Energy (Kw): 0.37-1.1

Weight(Kg): 500

Net Load(Kg): 100-6000

Mixing Rotatory Speed(rpm): 3 to 15

Dimension(mm): 1720*1920*400

Total Power Energy (Kw): 1.1-22

Weight(Kg): 450-8000

Net Load(Kg): 25-100

Mixing Rotatory Speed(rpm): 3 to 15

Dimension(mm): 1538*400*1282

Total Power Energy (Kw): 0.37-1.1

Weight(Kg): 180-320

| Model | Specifications | Details |

|---|---|---|

| V Shape Mixer/Blender | Capacity (L) | 20 to 500 |

| Design Volume (L) | 100 to 1000 | |

| Power (kW) | 1.5 to 3 | |

| Outlet Height (mm) | 550 to 700 | |

| Cone Mixer | Volume (L) | 300 to 2000 |

| Output (Kg/Tank) | 150 to 1000 | |

| Rotating Motor (kW) | 1.5 to 5.5 | |

| Mixing Motor (kW) | 1.5 to 5.5 | |

| Mixing Time (mins) | 0 to 30 | |

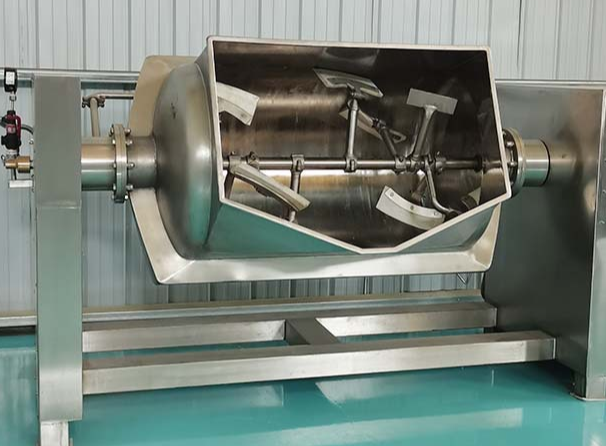

| Ribbon Mixer | Total Power Energy (kW) | 3 to 22 |

| Mixing Rotatory Speed (rpm) | 46 | |

| Barrel Volume (mm) | 680–2000 × 420–1068 × 490–534 | |

| Radius of Barrel (mm) | 210 to 534 | |

| Bin Blender Pharmaceutical | Max Loading Volume (L) | 1000 |

| Speed (rpm) | 3 to 11 | |

| Weight (kg) | 4000 | |

| Voltage | 400V, 3 Phases, 50 Hz | |

| Max Loading Weight (kg) | 400/batch | |

| Rotating Motor Power (kW) | 7.5 |

Our powder mixing machines are known for their versatility and find applications across various industries, such as:

PLC systems, sensors, and programmable mixing cycles streamline production and ensure consistency in products.

Automation and Control Options

Stainless steel body, which prevents microbial growth and ensures GMP compliance to maintain food and pharma grade hygiene.

Hygienic and GMP-Compliant

Safety interlocks and emergency stop buttons that protect the machine and operator during unexpected situations.

Safety interlocks and emergency stop buttonsThis includes various mixing methods for powder mixers, standard operating procedures (SOPs) for maintenance, and a list of recommended suppliers, etc.

Blending is one of the most crucial steps in manufacturing. It ensures that every dose of medicine has the right

Want to know the right way to use a double cone blender? The SOP for the double cone blender makes

Lots of things you see and use every day are made by combining different materials. Getting those materials mixed just

Do you know how protein powders and other chemical powders are mixed so evenly? That’s the magic of a ribbon

Ribbon mixers or blenders use a helical ribbon agitator within a U-shaped trough to mix materials. On the other hand, a V blender relies on a V-shaped chamber that rotates and causes materials to blend smoothly.

Depending on the machine, the typical mixing time of a powder mixing machine ranges from 1 to 3 minutes and 5 to 15 minutes.

It’s recommended that a powder mixer be cleaned after every mixing cycle to avoid cross-contamination, especially if it is used for pharmaceuticals.

Yes, we offer a one-year warranty for our powder mixing machines and lifetime customer support.

Yes, some of our powder mixers, especially those with planetary motion and high-shear capabilities, can be used for wet granulation.

Uniformity is non-negotiable. Inhomogeneous mixing can lead to doses that are sub-potent (ineffective) or super-potent (toxic), directly impacting patient safety and drug efficacy. It is a Critical Process Parameter (CPP).

The choice depends on material properties (cohesive, free-flowing, abrasive) and process needs (batch size, gentle vs. intense mixing).

Conical (V-Cone, Double Cone): Gentle, low-shear blending. Ideal for free-flowing powders and fragile granules. Good for homogeneity but can segregate.

Bin Blenders (Portable/Stationary): Efficient for large batches. Often used with intermediate bulk containers (IBCs) for contained transfer, minimizing dust and cross-contamination.

Ribbon/Paddle Blenders: Medium to high shear. Effective for cohesive powders, adding small quantities of APIs (active pharmaceutical ingredients) to excipients, or dry blending before granulation.

Fluidized/Silo Mixers (Plough Share, Mechanical Pneumatic): High-intensity mixing for very large volumes. Can handle challenging cohesive materials.

High-Shear Mixer Granulators: For wet granulation processes, where mixing and liquid binding occur simultaneously.

Selection is based on:

Material Characteristics: Particle size distribution, density, flowability, cohesiveness, abrasiveness, moisture sensitivity.

Process Requirements: Required uniformity, batch size, mixing time, need for heating/cooling jacketing, containment level (for potent compounds).

Regulatory & Cleaning: Must be designed for easy cleaning (CIP/SIP possible?) and comply with cGMP (materials of construction, documentation).

It’s the degree to which the active ingredient is distributed evenly. It’s measured by:

Sampling: Using thieves (sample probes) at predetermined locations (core, top, sides, discharge) after mixing.

Analysis: Chemically assaying samples (e.g., HPLC) for API content. The Relative Standard Deviation (RSD) or Content Uniformity (CU) must meet strict criteria (typically RSD < 5%).

In-Process Analytics: Newer techniques like NIR (Near-Infrared) spectroscopy allow for in-line or at-line monitoring without stopping the batch.

Hygienic Design: Stainless steel (typically 316L), polished surfaces (Ra value specified), no dead legs, crevice-free joints.

Cleanability: Easy to dismantle, or capable of CIP (Clean-in-Place). All product contact parts must be accessible for cleaning and inspection.

Documentation: Full traceability of materials, calibration records, maintenance logs, and batch records.

Safety & Containment: For potent or hazardous APIs, mixers require contained loading/unloading systems, split valves, and proper venting/filter systems to protect operators.

WhatsApp us

Available in a variety of sizes, from lab-scale units to industrial models. Also, they have different versions, such as cone mixers or ribbon mixers, that allow them to handle different types of materials.

Customizable Capacity