The scale of global commerce demands the annual production of billions of bottled products. From pharmaceutical tablets requiring verifiable hygiene to specialized cosmetics and mass-market beverages, this massive output requires uncompromising standards for both speed and quality. Manual processes simply cannot keep pace.

This is where the automated bottle packaging line rises to meet this severe challenge. This synchronized system is not a luxury, but a critical infrastructure investment that supports modern supply chains. If you are a manufacturer or business owner dealing with high-volume bottling, this integrated system can truly upscale your product quality, cost-efficiency, and market compliance.

Here is everything you need to know about bottle packaging lines, including how they work and the benefits they offer your business.

What is a Bottle Packaging Line?

A bottle packaging line, often called a bottling line or filling line, is a complete system of machinery. Its main purpose is to take empty bottles and process them through all necessary stages, including cleaning, filling, capping, and labeling, until they become market-ready products.

This type of automated machinery is widely used across different industries such as pharmaceuticals, cosmetics, and chemicals. They are designed to maximize production speed and achieve impeccable product quality and safety.

Five Main Components of a Bottle Packaging Line

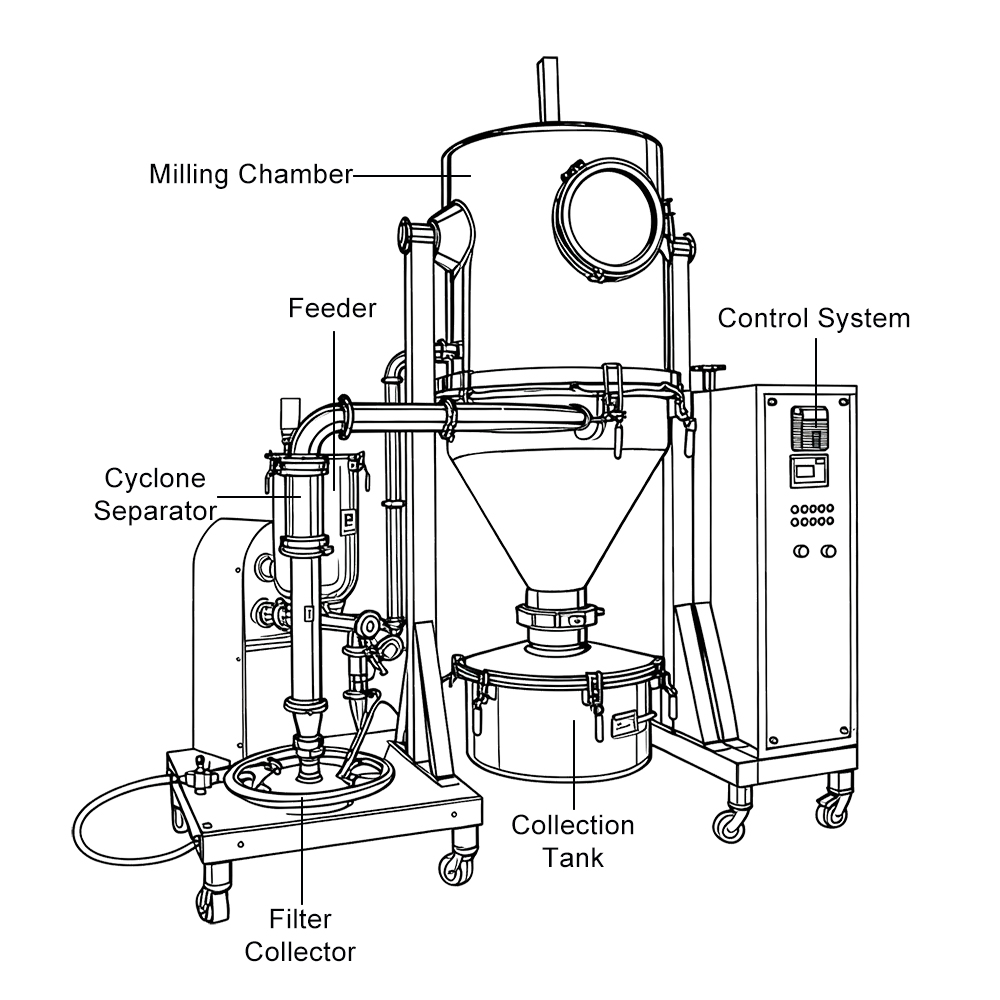

A bottle packaging line consists of various machines and equipment that work together in a connected sequence. Some of them may include bottle unscramblers, filling, and capping machines. Let’s take a look at them one by one.

Component #1: Bottle Unscrambler

A bottle unscrambler is a machine that automatically sorts and orients empty bottles. It takes them from a jumbled bulk mass and places them into a single-file, upright line for the main production line. This first step is extremely important for an organized flow of containers.

Component #2: Bottle Rinser

It is a device used to clean the interiors of a container. A rinser uses a pressurized spray of water, ionized air, or a sanitizer solution to quickly and thoroughly clean the inside of bottles. The goal is to remove them from any debris, dust, and foreign particles.

Component #3: Filling Machine

The filling machine is the core component of the bottle packaging line. It is designed to automatically draw liquid, powder, or viscous material from a supply tank and fill the bottle to the desired level or volume.

These machines are equipped with various sensors and control mechanisms to fill each bottle with the correct amount of liquid.

Component #4: Sealing and Capping Machine

The contents of the bottles must be protected from contamination, spillage, or tampering. Capping and sealing machines apply various types of closures, such as screw caps, corks, or foil seals, to the bottles and tighten them. It keeps the product fresh and safe until it reaches the customer.

Component #5: Conveyor System

The conveyor system is a continuous belt or chain that physically moves bottles along the line. It links every machine, coordinating container movement and enabling the entire automated process to function as a single system.

How Does a Bottle Packaging Line Work: Step-by-Step Process

A bottle packaging line is a crucial part of the automated inline packaging system. The entire setup is a synchronized unit from the point of entry to the final packaging station. Here is how the process takes place:

1. Bottle Feeding and Orientation

The process starts with an unscrambler, which automatically receives bulk empty bottles and orients them upright on the conveyor. An operator monitors the entire process to ensure a smooth, steady supply to the rest of the line.

2. Rinsing

Next, the bottles enter a rinsing machine that cleans and sterilizes containers using air, water, or a chemical rinse. Rinsing is an absolute must for pharmaceutical and food products to prevent contamination and maintain strict hygiene standards.

3. Filling

In the next step, the bottles move under the nozzles of a filling machine. The type of filler used depends on the product. Liquids may use gravity (for thin products like water), a piston (for thick products like creams), or pressure overflow (for consistent level fills). For tablets and capsules, a tablet counting machine accurately dispenses a specific number into each container.

4. Capping and Sealing

After filling, the bottles move to a Capping Station where lids and caps are applied. This machine ensures a proper and secure seal, often using rolling friction or specific torque to guarantee a leak-proof closure.

5. Labeling and Coding

All Steps Image Source: YouTube

A labeling Machine applies primary labels for branding and product information. Similarly, a coder applies essential information like batch numbers, expiration dates, and sometimes QR codes or barcodes for supply chain tracking and quality control.

6. Final Packaging

In the final stage, bottles are grouped, placed into cases or cartons by a case packer, and often shrink-wrapped or palletized. This step prepares the market-ready product for storage, transport, and final distribution.

Key Features and Benefits of a Bottle Packaging Line

More than just a packaging process, a bottle packaging line is a strategic investment in your business. From high-speed automation to strict quality assurance, it is a comprehensive solution for mass production. Below are some of the key features and benefits:

1. High Speed Automation

The biggest advantage of a bottle packaging line is its high-speed automation and control. Automated lines can operate at very high speeds, filling, capping, and sealing thousands of bottles per hour. This capacity is way superior to manual labor and enables manufacturers to meet massive market demand.

2. Consistency and Quality Control

Certain pharmaceutical products require a highly sterilized and controlled environment. Automation eliminates human error in manual labor and makes sure that every bottle is filled, capped, and labeled identically. Less human contact with the product drastically reduces the risk of contamination and microbial growth.

3. Product Versatility

Advanced bottle packaging lines are capable of handling a variety of products, as well as different bottle shapes, sizes, and materials. This flexibility is managed through a central control system, often a PLC (Programmable Logic Controller). It allows operators to program specific settings for different products and bottle types quickly.

4. Enhanced Productivity

An automatic bottle packaging line increases the speed and production volume. It allows you to meet higher market demands within tight deadlines. The automation of repetitive tasks reduces the need for extensive manual labor and helps businesses to reallocate personnel to more complex, value-added roles.

5. Cost Saving

Bottling line equipment is designed to handle most of the labor-intensive tasks, from cleaning bottles to filling them with liquid. This automation directly helps you save money on labor costs.

Not only does it reduce staffing needs, but advanced sensors enable features like “no bottle, no fill.” These features reduce costly waste from spills, overfilling, and incorrectly applied labels.

Furthermore, industrial bottling equipment is built for durability and lasts for many years, so you do not have to worry about frequent equipment maintenance or replacement.

Applications of Bottle Packaging Line

Bottle packaging lines align with the needs of many high volume and quality-driven industries. This is because these systems are designed to meet both regulatory and consumer demands. Let’s discuss different industries where bottle packaging lines are essential.

1. Pharmaceutical Industry

The pharmaceutical industry is perhaps one of the biggest consumers of bottle packaging. They are used to packing medications, vitamins, and supplements (both liquid and solid doses). It helps manufacturers adhere to Good Manufacturing Practices (GMP) guidelines, which demand absolute cleanliness, verifiable accuracy in dosing (e.g., tablet counting), and tamper-evident sealing.

2. Cosmetics and Personal Care

In the cosmetics and personal care sector, packaging lines handle a wide range of products. This can be thin perfumes and viscous shampoos to thick lotions and creams. These packaging lines also maintain brand aesthetics on the shelf, with flawless label alignment and placement on uniquely shaped bottles.

3. Beverage and Food Industry

In the beverage and food industry, bottle packaging lines deal with bottled water, soft drinks, sauces, oils, etc. For this sector, high-speed output is key to meeting mass-market demand.

The lines use specific filling technologies, such as gravity or pressure fillers, to handle different liquids. Bottle packaging lines maintain food safety standards through sterile rinsing and airtight capping to preserve freshness and shelf life.

Take the Next Step to Optimize Your Production

A fully automated bottle packaging line system is absolutely essential for speed, quality assurance, and adherence to strict hygiene standards. Consider this investment as securing market leadership and consumer trust.

Whether you are launching a new product line or looking to scale up production capacity, a reliable partnership with an expert manufacturer is crucial. You must invest in high-quality, durable packaging machinery that stands the test of time and regulatory scrutiny.

At Finetech, we help you automate, optimize, and future-proof your business. From delivering the best pharmaceutical bottle packaging line to offering on-site training and sample proofing, we provide everything you need. Get in touch with Finetech today and see how we can transform your production floor.

References

TOP 10 Packaging Line Manufacturers In The World.

Packaging Line Equipment | Everything You Need to Know.