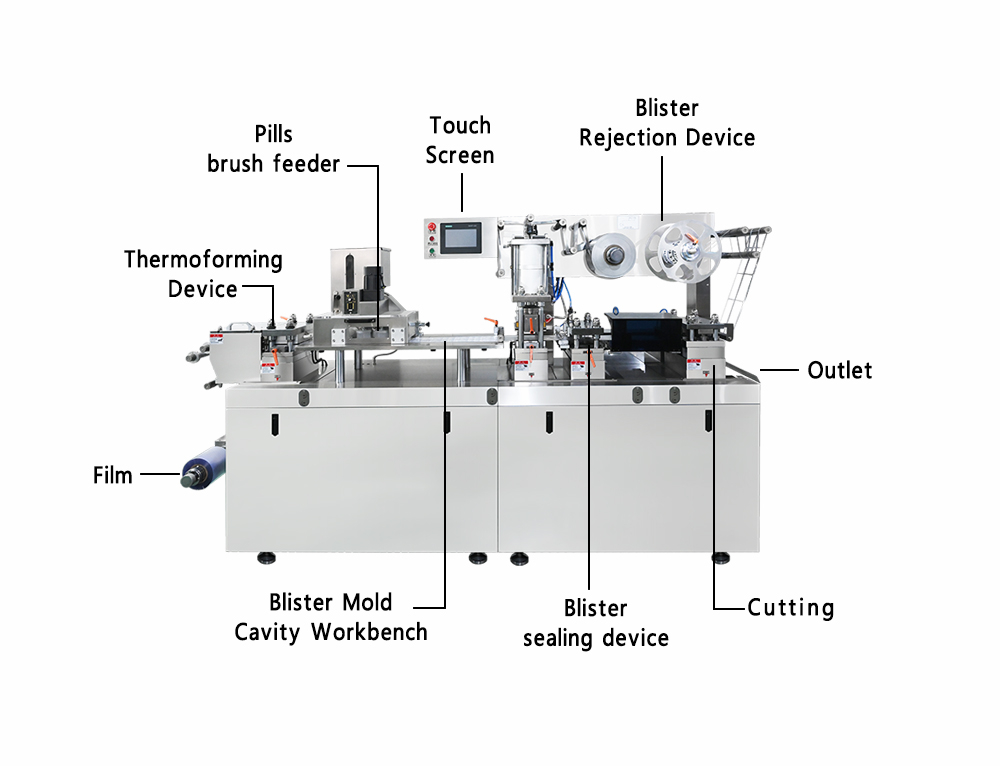

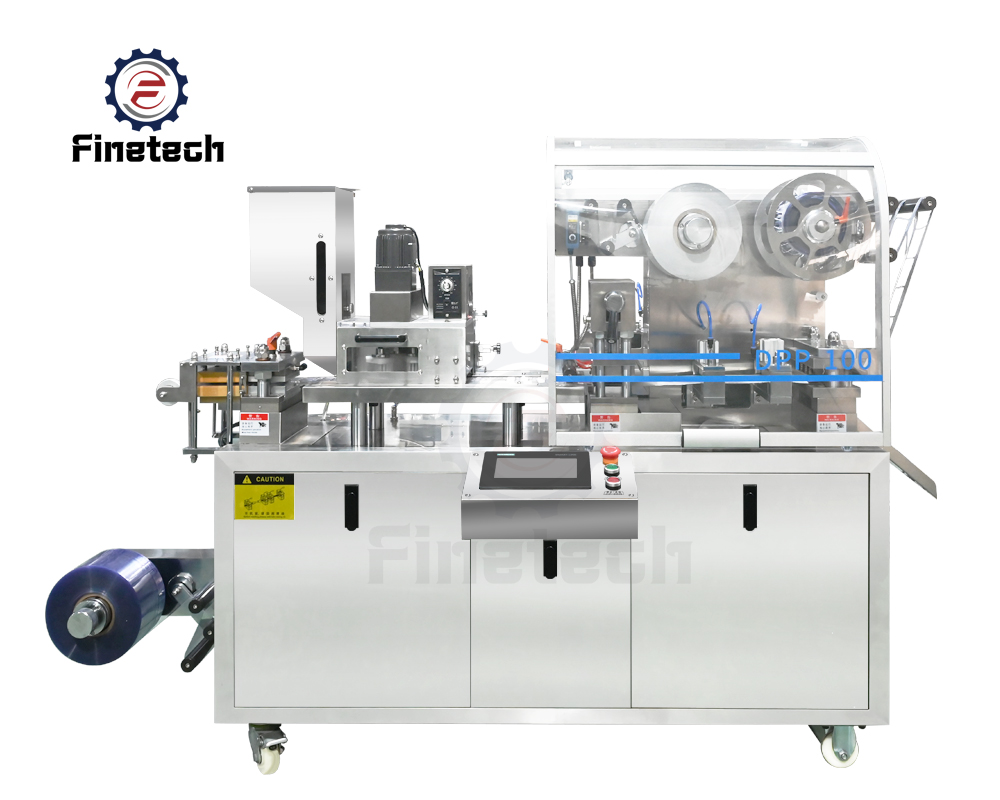

DPP-180 Alu Alu and PVC Blister Packing Machine

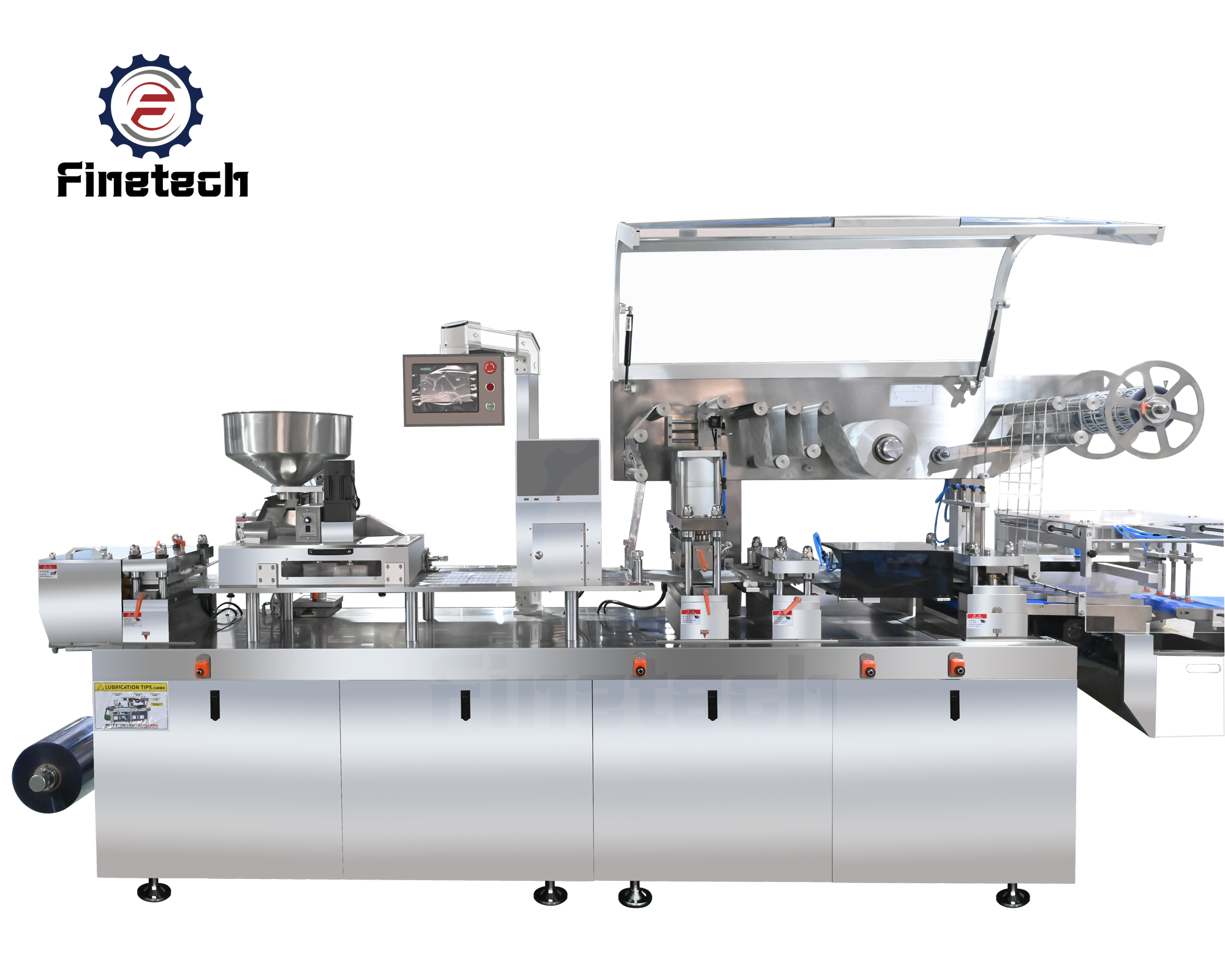

The DPP-180 is a high-speed automatic blister packaging machine made for large-scale packaging of medicines, medical devices, and valuable products. It works with both aluminum-plastic (16–24 mm cavity size) and aluminum-aluminum blister packs. It supports continuous production and smart data tracking.

Need a Custom Quote?

Or More information About this product? Contact our sales stuff today!

Key Features

Technical Data

Machine Details

FAQ

Application

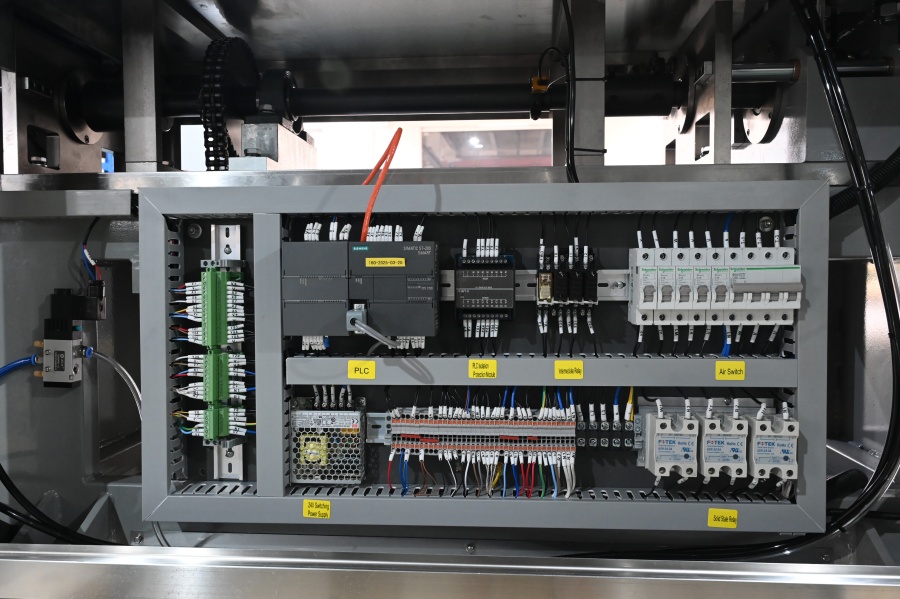

1. The bilingual (Chinese-English) touchscreen control panel is simple and easy to use. The PLC display and touchscreen enable intelligent operation.

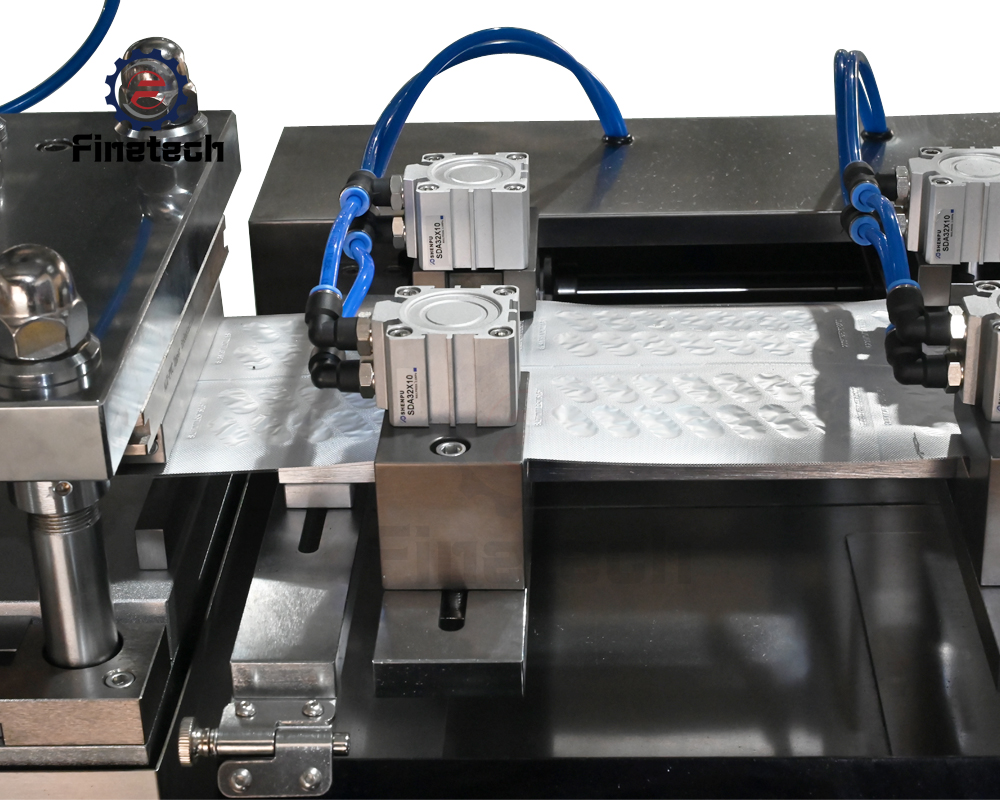

2. The machine has two separate functions: PVC forming, filling, and heat sealing are in one section; tropical aluminum cold forming, heat sealing, and punching are in another section. It supports separate packaging and is equipped with an automatic waste film rewinding mechanism for uniform waste collection and orderly blister plate output.

3. Stable performance: Equipped with a photoelectric detection, correction system, and driven by a servo motor to ensure long-distance, multi-station synchronous stability. Printed packaging with image/text alignment enhances the packaging’s visual quality.

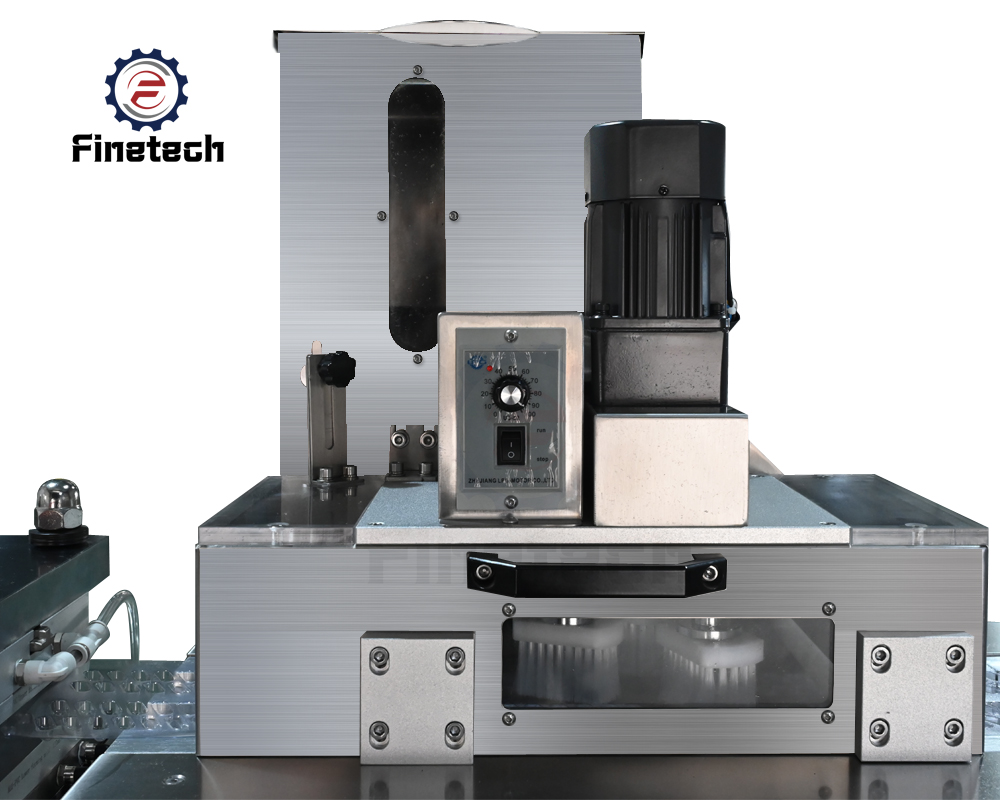

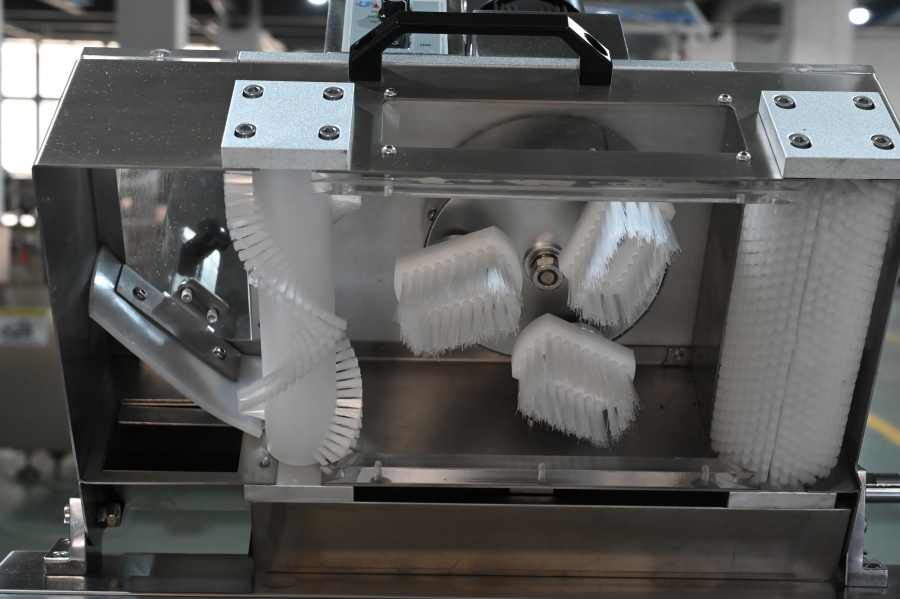

4. External feeding device: The automatic feeding system handles capsules, tablets, milk tablets, and other materials, eliminating manual feeding time, reducing labor costs, and increasing production efficiency.

5. The internal wiring of the machine cabinet is clean and well-organized—not only for aesthetics but also to make wiring paths clear at a glance, greatly simplifying error diagnosis and troubleshooting.

| Model | DPP-180 Blister Packing Machine |

| Production Capacity | 40,000-80,000 Blister plates/h |

| Cutting Frequency | 20-40 strokes per minute (Aluminum-Plastic) 10-40 strokes per minute (Aluminum-Aluminum) |

| Adjusting range of travel | 40-125mm |

| Max. forming area | 170x120mm (Aluminum-Plastic) 160x120mm (Aluminum-Aluminum) |

| Max. forming depth | 14mm (Standard Machine) Custom Machine: 26mm (Aluminum-Plastic) 18mm (Aluminum-Aluminum) |

| Size of standard plate | 80X57mm |

| Power supply | 380V 50HZ 5.5Kw |

| Main motor | 1.5Kw |

| Air demand | ≥0.2m³/min |

| Air pressure | 0.4-0.6Mpa |

| Cooling of mold | Circulating water consumption ,5OL/H |

| Width and thickness of PVC and PTP | Pharmaceutical PVC: 180 x 0.2 – 0.5 mm Aluminum Foil PTP: 180 x 0.02 – 0.03 mm |

| Overall size | 2670x600x1530mm |

| Weight | 1000 kg (Net Weight) 1150 kg (Gross Weight) |

The primary difference is the maximum blister format size. The DPP-180 can handle larger blisters, typically up to 180mm x 180mm or similar, allowing for larger packs or more cavities per blister. It is generally a more heavy-duty machine with a higher potential output.

The DPP-180 is faster than the DPP-150, with typical speeds ranging from 120 to 200 blisters per minute, depending on product size, blister design, and machine configuration.

As the model number suggests, the maximum forming area is typically 180mm x 180mm. Always consult the specific technical data sheet for your machine's exact capabilities, as the pocket depth and material type can affect the usable area.

It is compatible with standard blister packaging materials:

Forming Film: PVC, PP, PET, PVDC-coated films, Aclar®, and other thermoformable plastics.

Lidding Material: Hard-temper aluminum foil (printable or plain), paper/foil/poly laminates, and peel-push foils.

Yes, manufacturers often offer a DPP-180C (or similar designation) model specifically designed for cold-forming aluminum/aluminum blisters, which are essential for the most sensitive pharmaceutical products.

It can be equipped with various feeders:

Standard: Vibratory bowl feeders for tablets and capsules.

Advanced: For complex shapes or fragile products, volumetric piston feeders, multi-bowl systems, or even robotic pick-and-place units can be integrated.

Due to its larger size and potentially more complex tooling, changeovers can take 45 to 90 minutes. However, many modern DPP-180 machines are equipped with quick-change systems (e.g., cassette-style mold systems, centralized clamping) to reduce this time significantly.