NJP-2000/2500 Automatic capsule filling machine

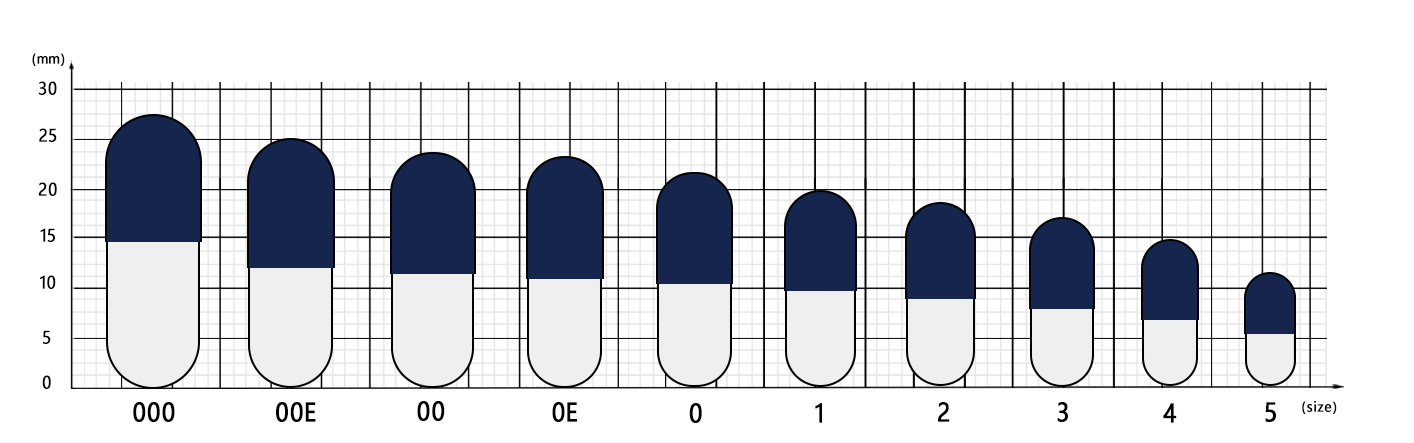

This product is designed for very large pharmaceutical production lines. It offers very high speed, stability, and fully automatic, unmanned operation. It is ideal for large-scale filling of premium products like capsules, anticancer microspheres, and functional foods. The machine works with standard capsules sized 000# to 5# and supports MES system integration. It can meet annual production needs of 1,000,000-5,000,000 hard capsules.

Need a Custom Quote?

Or More information About this product? Contact our sales stuff today!

Key Features

Technical Data

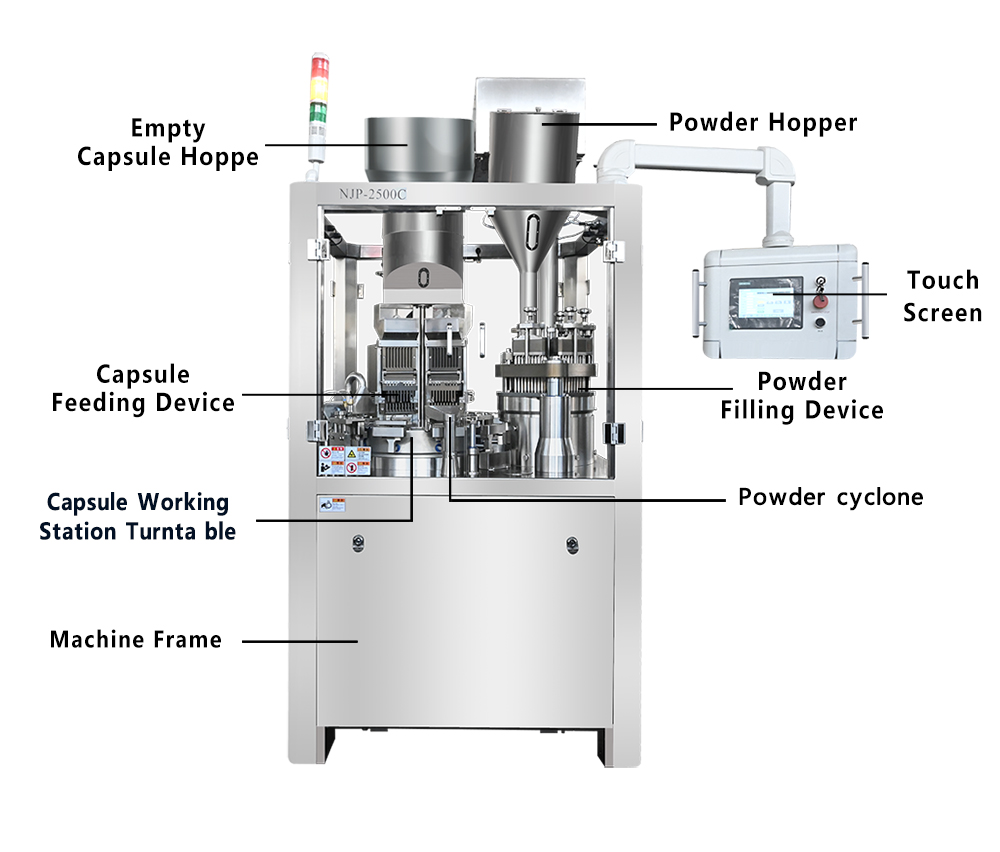

Machine Details

FAQ

Application Capsule Size

Application Capsule Types

1. The machine runs automatically with intermittent rotation, performing capsule feeding, rejecting bad capsules, locking, and cleaning molds all at once. This ensures accurate positioning and low noise.

2. It is controlled by a computer with adjustable speed and a clear digital display, making operation easy.

3. The machine works well with different types of capsules and has a high production rate. It can fill both traditional Chinese and Western medicines using a multi-hole plunger system for accurate dosing that meets national standards.

4. It includes safety features to protect users and the machine, such as automatic stopping when materials run out. The machine operates smoothly and reliably, making it ideal for manufacturers producing hard capsules.

| Model | NJP-2000 | NJP-2500 |

| Productivity | 120,000 capsules/h | 150,000 capsules/h |

| Motor power | 6.45Kw | 6.45Kw |

| Power supply | Standard : 3P 380V 50Hz , Can be Customized | Standard : 3P 380V 50Hz , Can be Customized |

| Capsule size | 00#~5# and safety capsule A~E | 00#~5# and safety capsule A~E |

| Capsule using rate | ≥ 99.5% | ≥ 99.5% |

| Machine weight | 1500 Kg | 1500 Kg |

| Overall dimension | 1000*1050*1950mm | 1000*1050*1950mm |

| Noise index | ≤ 75 DBA | ≤ 75 DBA |

| Dosage difference | ≤ ±3% (under more than 300mg dosing and 40~80 mesh after granulation) | ≤ ±3% (under more than 300mg dosing and 40~80 mesh after granulation) |

| Compressed air | air consumption 0.06m3/min pressure 0.3Mpa | air consumption 0.06m3/min pressure 0.3Mpa |

| Water supply | Water cycle pump compound water tank, or meet water source | Water cycle pump compound water tank, or meet water source |

| Vacuum degree | -0.02~-0.06 MPa | -0.02~-0.06 MPa |

| Water supply | 500L/H 0.2-0.10 Mpa | 500L/H 0.2-0.10 Mpa |

| Enter pipe inner-diameter | 20mm | 20mm |

| Water Spout inner-diameter | 27mm | 27mm |

| Working temperature | 21℃ ± 3℃ | 21℃ ± 3℃ |

| Working relative humidity | 40-55% | 40-55% |

| Dust Collector | 160m3/h | 160m3/h |

| Special function | Granule and powder mixed filing; Powder collector | Granule and powder mixed filing; Powder collector |

| Control system | Stepless frequency conversion control , PLC touch screen | Stepless frequency conversion control ,PLc touch screen |

| Material | Spare part contact with medicine adopts superior S.S 304 & GMP-compliant material | Spare part contact with medicine adopt superior S.S 304 & GMP compliable material |

| Criterion | Comply with GMP completely | Comply with GMP completely |

The NJP 2000 can handle a wide range of capsule sizes from 000 (largest) to 5 (smallest). You need to change the dosing disc and the capsule holding ring to match the specific capsule size you are using.

Yes. The NJP 2000 is primarily designed for powders but is also excellent for filling micro-pellets, granules, and small beads. The key is selecting the correct dosing disc and using proper techniques (like tamping for powders) to ensure accurate fill weight.

Yes, it is designed for easy cleaning. The main components like the capsule holding ring, dosing disc, powder tray, and base plate can be quickly disassembled without tools for cleaning and sanitization.

The fill weight is controlled by two main factors:

Dosing Disc Thickness: Thicker discs have deeper holes and hold more product. You must use the disc thickness specified for your capsule size.

Powder Bed Height: The adjustable knob on the side of the machine raises or lowers the powder tray, which changes how much powder is available to fill the dosing holes. A higher powder bed = heavier fill weight.

Cleaning: Clean after every use or product changeover.

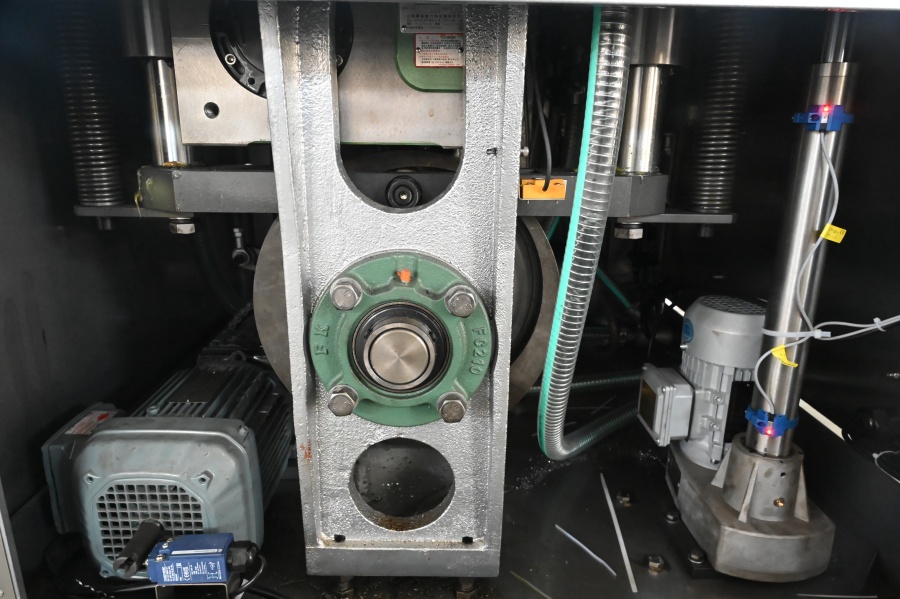

Inspection: Regularly check the rubber suction nozzles for wear and tear.

Lubrication: Lightly lubricate the moving shafts and bushings as per the manufacturer's instructions.

Storage: Store the machine disassembled and in a dry, clean place.

Rubber Suction Nozzles (the most frequently replaced part).

Dosing Discs for the capsule sizes you use most often.

Capsule Holding Rings for your capsule sizes.

Tamping Pins & Springs.

Powder Scraper Blade.

Manuals and parts lists are often available from the supplier you purchased the machine from. Many video tutorials demonstrating setup, operation, and cleaning for the NJP 2000 can be found on platforms like YouTube. Search for "NJP 2000 setup" or "NJP 2000 cleaning."