Vial Cartoning Machine: Your Ultimate Guide 101 In 2026

A vial cartoning machine is the heart of pharmaceutical packaging. It quietly shapes how fragile vials move from production to

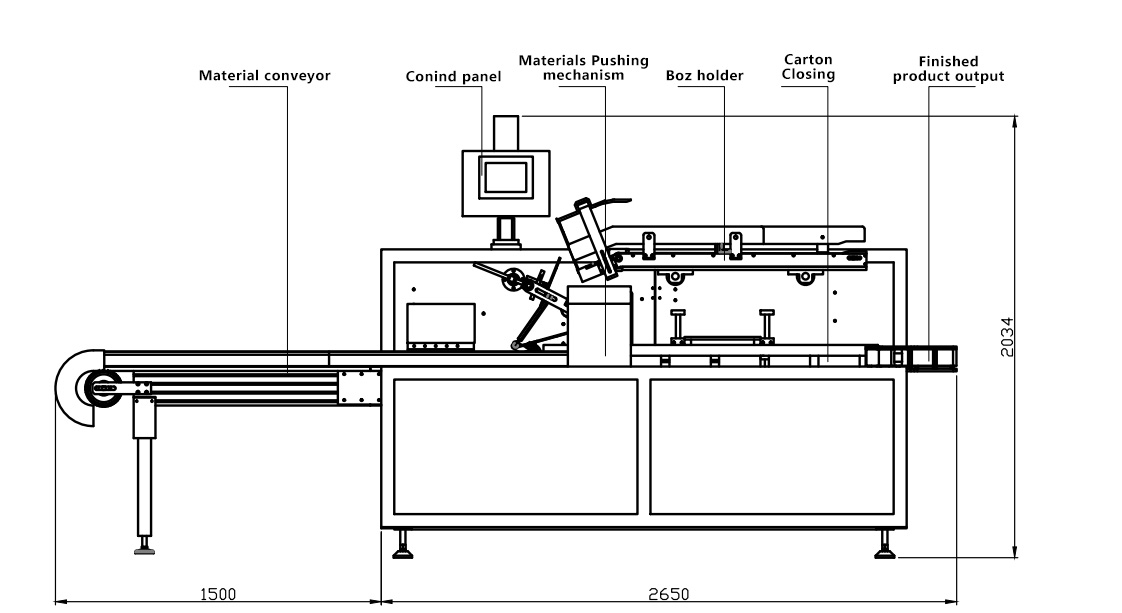

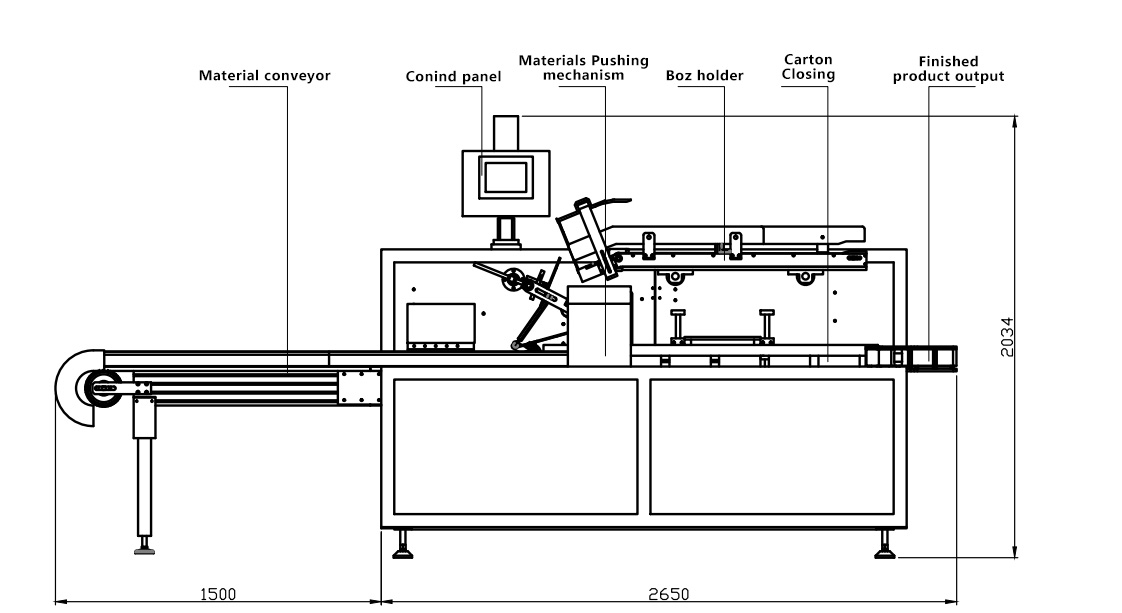

Automatic Cartoning Machine is a sophisticated packaging machine designed to automatically form cardboard cartons from flat blanks, insert products (and any required inserts like leaflets or spoons), and close the carton through tucking, gluing, or a combination of both. It is a core component in high-speed production lines across multiple industries.

Increase packaging efficiency with our automatic cartoning machines. Perfect for pharmaceuticals, food, and consumer goods. High-speed, reliable, and easy to integrate.

Cartoning Speed: 30-120 cartons per minute

Machine Dimensions: 2,650 mm x 1,300 mm x 1,900 mm

Air consumption: 120-160 L/minute

Cartoning Speed: 150 boxes per minute

Size: 3,300 mm x 1,500 mm x 2,200 mm

Applicable Products: Blister plates, soaps, medicine bottles, cosmetics, health products.

Cartoning Speed: 30-80 cartons per minute

Machine Dimensions: 2,700 mm x 1,140 mm x 1,800 mm

Weight: 1,200 Kg

| Items | FTZH-120 | FTZH-130 | FTZH-180 | |

|---|---|---|---|---|

| Packing speed | 50-80 (Cartons/Min) | 30-120 (Cartons/Min) | 80-150 (Cartons/Min) | |

| Carton | Quality requirement | 250-350g/m2 | 250-450g/m2 | 250-500g/m2 |

| Dimensions (L*W*H) | (65-125)*(30-85)*(12-50)mm | (80-250)mm×(90-170)mm | (80-250)mm×(90-170)mm | |

| Instructions | Quality requirement | 60-70g/m2 | 60-70g/m2 | 60-70g/m2 |

| Unfolded size | (80-250)*(90-170)mm | (80-250)*(90-170)mm | (80-250)*(90-170)mm | |

| Folds | 1-4 fold(s) | 1-4 fold(s) | 1-4 fold(s) | |

| Operation pressure | ≥0.6mpa | ≥0.6mpa | ≥0.6mpa | |

| Air consumption | 120-160L/min | 120-160L/min | 120-160L/min | |

| Power supply | 220V, 50Hz or 380V, 50Hz | 220V, 50Hz or 380V, 50Hz | 220V, 50Hz or 380V, 50Hz | |

| Main motor power | 0.75KW | 0.75KW | 0.75KW | |

| Overall dimensions (L*W*H) | 2700mm×1140mm×1800mm | 2650mm×1300mm×1900mm | 3300mm×1500mm×2200mm | |

| Net weight | 1200Kg | 1600Kg | 1800Kg |

The pusher quickly slides materials into the box and seals it smoothly.

Pushing Mechanism

The box opener uses double suction heads to lower the box and open it twice to ensure ease of use and reliable opening.

Box-Opening MechanismThis covers a wide range of knowledge about capsule filling equipment, including maintenance standard operating procedures, purchasing advice, supplier recommendations, and working principles, etc.

A vial cartoning machine is the heart of pharmaceutical packaging. It quietly shapes how fragile vials move from production to

From pharmaceuticals to cosmetics and even everyday consumer goods, blister cartoning machines have taken over packaging. Cartons are no longer

Many companies around the world build special equipment for factories. These machines are a key part of making things like

Have you ever wondered how products like toothpaste, medicine boxes, or snack bars end up so perfectly packed in cartons?

Speed (cartons per minute)

Carton Size Range (adjustability for different products)

Automation Level (manual, semi-automatic, or fully automatic)

Product Compatibility (rigid/flexible, shape, weight)

Sealing Method (glue, tuck-in, or heat seal)

Yes, we can customize the mold and machine structure for your carton. You can visit our custom packaging machinery service page for more details.

Semi-automatic: 10-30 cartons per minute (CPM)

Fully automatic: 50-400+ CPM (high-speed models)

Regularly clean and lubricate moving parts.

Inspect sensors and pneumatic systems.

Replace worn belts, grippers, and seals.

Follow the manufacturer’s maintenance schedule.

Semi-automatic: $10,000-$50,000

Fully automatic: $50,000-$300,000+

An automatic cartoning machine takes flat cardboard blanks, forms them into open boxes, inserts your product (and any required inserts like leaflets or spoons), and then closes the carton—all without manual intervention. It automates the final “boxing” stage of your packaging line.

They are essential in industries with high-volume, consistent packaging needs:

Pharmaceuticals: For boxing blisters, bottles, vials, and syringes, with mandatory patient information leaflets.

Food & Beverage: For tea bags, snack bars, pouches, powdered mixes, and ready-to-eat meals.

Cosmetics & Personal Care: For perfume boxes, skincare sets, toothpaste, and soap.

Consumer Goods & Electronics: For batteries, lightbulbs, razors, and small accessories.

Medical Devices: For sterile and non-sterile kits.

Vertical Cartoner: The carton is formed and moves vertically. Products are typically dropped in from above. Best for single, free-flowing items like bottles, vials, or pouches. Often more space-efficient.

Horizontal Cartoner: The carton lies on its side and moves horizontally. Products are pushed in from the side. Ideal for stacked items, blister packs, fragile products, or when inserting multiple components (like a product + leaflet).

Speeds vary widely based on machine design and product complexity:

Intermittent motion (starts and stops): 60 – 150 cartons per minute (cpm). More precise for complex loading.

Continuous motion (constant speed): 200 – 400+ cpm. For high-speed, simpler applications.

Your specific speed requirement depends on your upstream equipment and overall line goals.

The three main methods are:

Tuck Closure: Flaps are mechanically folded and tucked. Common for retail boxes that may be opened and closed by the consumer. Cost-effective, no glue required.

Hot-Melt Glue Closure: A dab of fast-setting adhesive seals the flaps. Provides a tamper-evident, secure seal preferred for pharmaceuticals and for superior shelf appearance.

Lock-style/Pre-glued: Uses pre-applied adhesive or interlocking tabs. Simpler but may be less secure.

The “best” method depends on your product needs (security, aesthetics, customer experience) and operational costs.

Modern machines are designed for quick changeover. This involves changing mechanical parts like the carton magazine, forming heads, and pusher arms. Higher-end machines feature tool-less changeovers and digital memory to recall settings, reducing downtime from 30+ minutes to under 10 minutes. Always request a changeover demonstration.

Absolutely. A key consideration is integration capability. A good cartoner should easily connect (via PLC or Ethernet) with your upstream equipment (e.g., blister machine, filler, labeler) and downstream equipment (e.g., bundler, case packer) to create a seamless, automated line.

WhatsApp us

We have simplified the operational settings so that you can learn how to operate our machines in 5 minutes.

Siemens PLC Control Panel