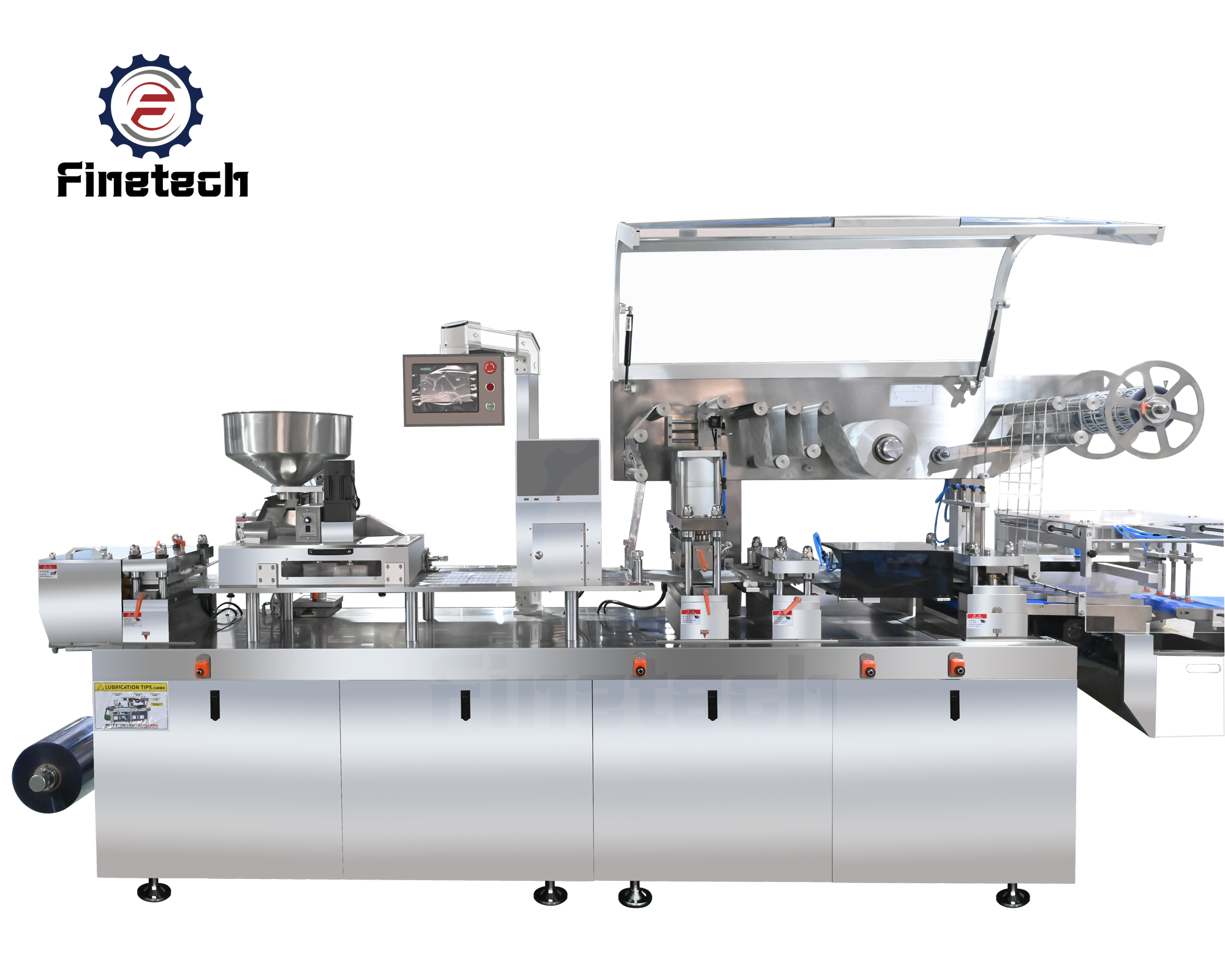

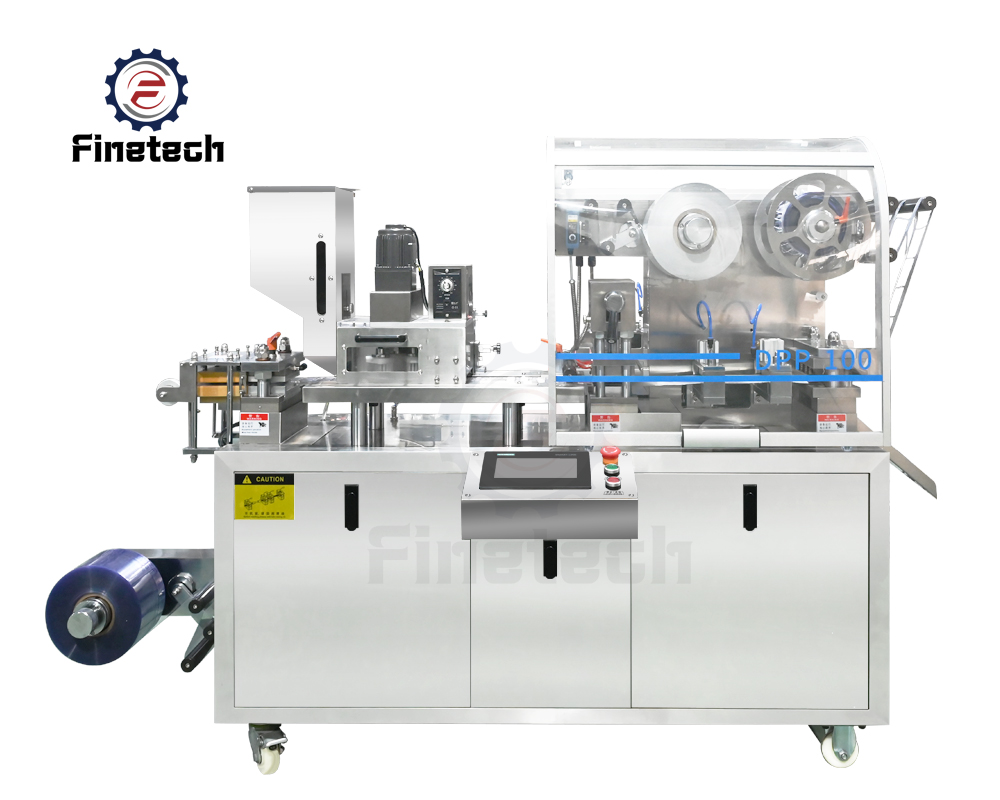

DPP-250/260 Blister Packing Machine

The DPP-250 is a high-speed automatic blister packaging machine with multi-axis servo drives and PLC+HMI smart control. It is made for the pharmaceutical, medical device, and food industries, and is ideal for individually sealed packaging of tablets, capsules, sensors, and similar products.

Need a Custom Quote?

Or More information About this product? Contact our sales stuff today!

Key Features

Technical Data

Machine Details

FAQ

Application

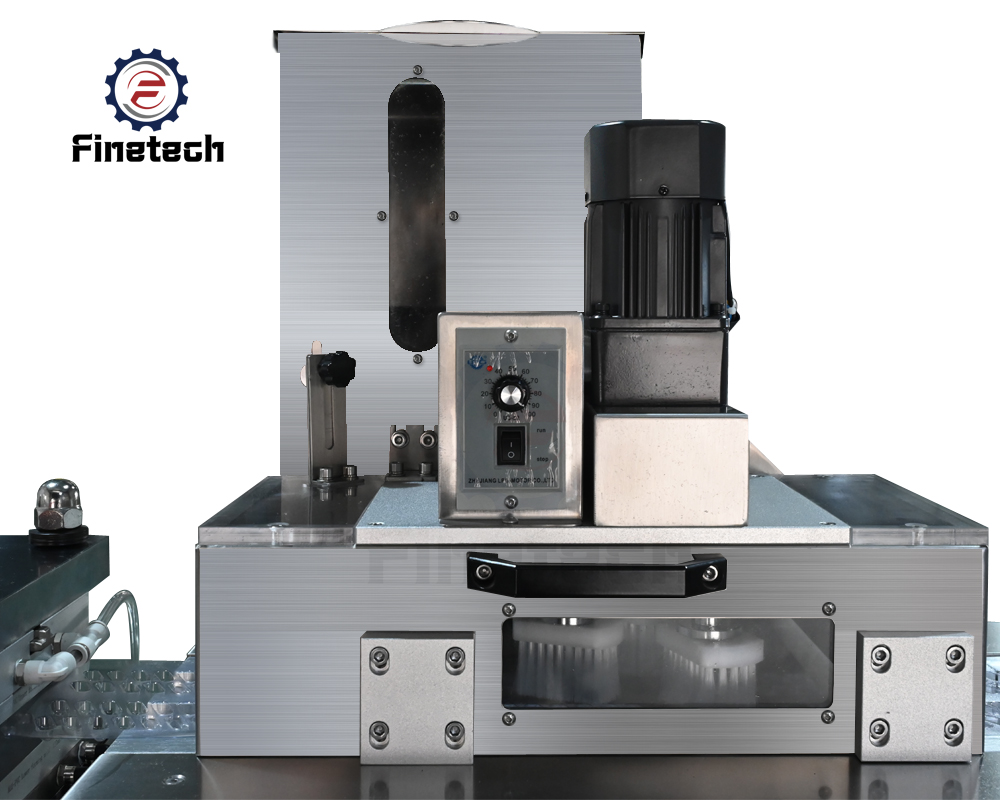

- Simple Structure: The transmission system is improved from the original, allowing a wider forming range, more precise movement, and quieter operation.

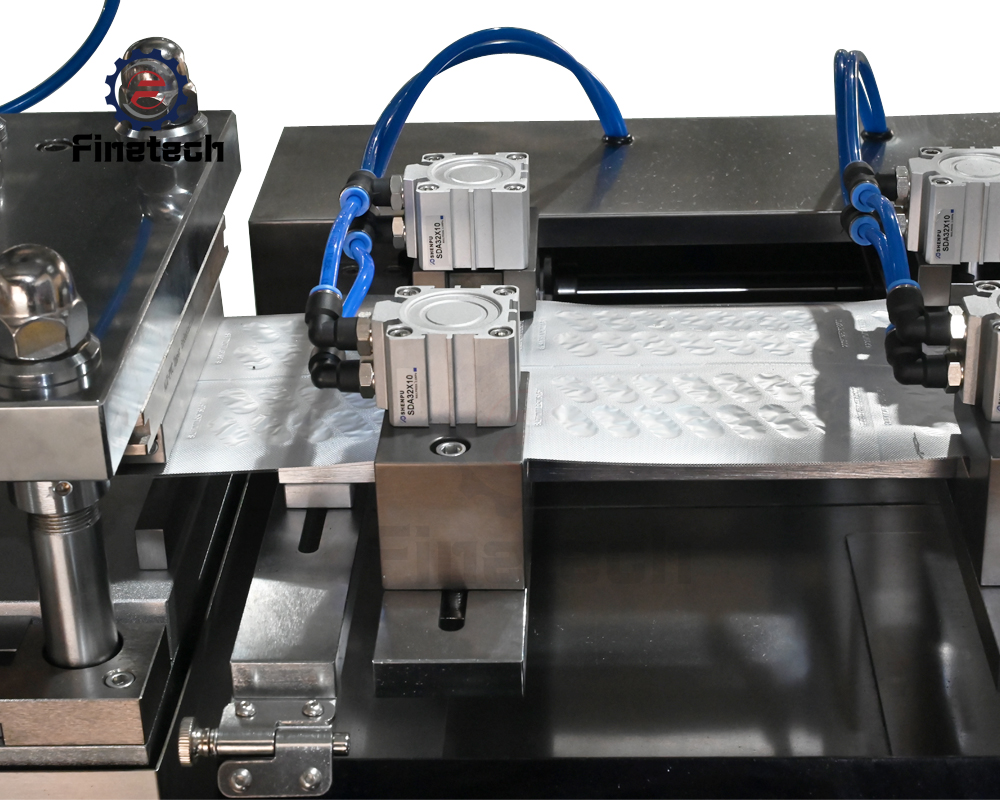

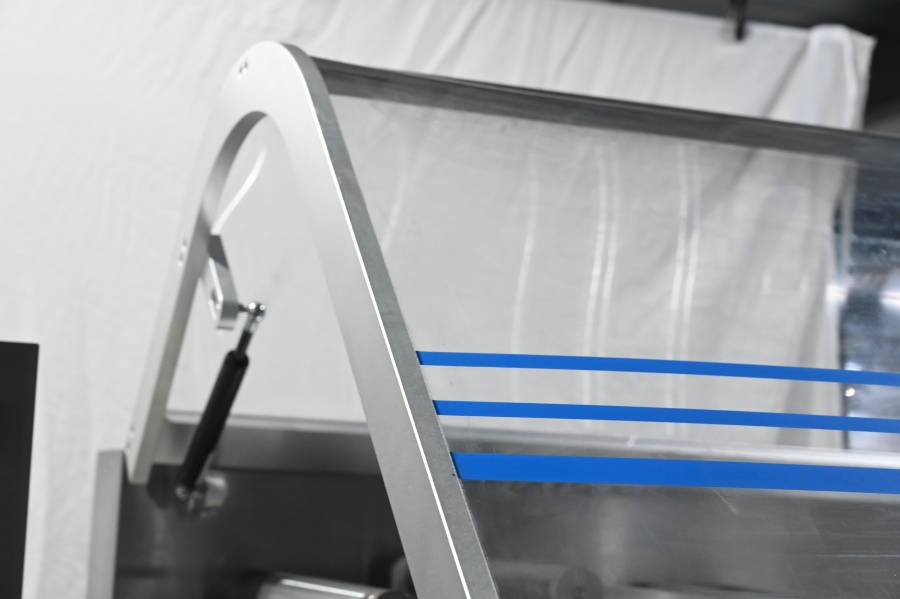

DPP 250 Blister Packaging Machine Diagram - Pneumatic-Clamp Servo Traction: Stable and easy to adjust, ensuring smooth and reliable film feeding.

- Dual Registration Forming: Dual-clamp servo traction guarantees accurate alignment of printed materials.

- Punching and Pushing Device:Keeps finished products from staying in the mold, preventing damage and waste.

- Customizable Options:Supports features like color mark alignment and vision inspection, with reserved space for easy installation.

| Model | DPP-250 |

| Packaging Capacity | 18k-236k capsules/hour |

| Cutting Frequency | 20-45 strokes/min (Aluminum-Plastic) 10-40 strokes/min (Aluminum-Aluminum) |

| Adjusting range of travel | 40-130mm (Customizable 40-160 mm) |

| Max. forming area | 130x260mm |

| Max. forming depth | 14 mm (Standard Machine) Custom Machine: 26 mm (Aluminum-Plastic) 18 mm (Aluminum-Aluminum) |

| Size of standard plate | 80x57mm |

| Power supply | 380V 50HZ 7.5Kw |

| Main motor | 2.2Kw |

| Air demand | ≥0.3m³/min |

| Cooling of mold | Circulating water consumption. 6OL/H |

| Width and thickness of PVC and PTP | Pharmaceutical PVC: 270 x 0.15 – 0.45 mm Aluminum Foil PTP: 270 x 0.02 – 0.03 mm Hard Aluminum: 260 mm |

| Overall size | 3700x720x1650mm |

| Weight | 1800kg (Net Weight) 2000kg (Gross Weight) |

The DPP-250's main advantage is its large format and high speed. It is designed for:

Packaging large products (e.g., medical device kits, large tablets, pouches).

Creating blisters with a very high number of cavities (e.g., 30+ tablets per blister).

Achieving maximum production output, often for primary packaging lines with high annual volumes.

Calendar blister packs for full-course doses.

As a high-speed machine, the DPP-250 typically operates in the range of 150 to 250+ blisters per minute. The actual speed is highly dependent on the blister size, product complexity, and feeding system.

This is its defining feature. The DPP-250 can handle large blister formats, typically up to 250mm x 250mm or even larger in some configurations. Always verify the specific technical data sheet for the maximum draw depth and usable area.

It handles all standard thermoformable films and lidding materials, but on a larger scale:

Forming Web: PVC, PP, PET, PE, Aclar®, and high-barrier co-extrusions.

Lidding Material: Hard-temper aluminum foil (printable or plain), paper/foil/poly laminates, and child-resistant lidding.

Changeover on such a large machine can be complex. Without quick-change systems, it can take 90 minutes to 3 hours. Investing in fully automated or cassette-based quick-change tooling is highly recommended to reduce this downtime to 30 minutes or less.

The tooling is larger, heavier, and more substantial:

Large Forming Mold and Plug-Assist Assembly

Large Sealing Die (often with multiple heating zones for consistent temperature)

Large, multi-cavity Cutting Punch and Die

Corresponding feed rails and guide plates.

As a capital asset in a regulated industry, the manufacturer should provide a full suite of documentation, including:

Factory Acceptance Test (FAT) & Site Acceptance Test (SAT) protocols.

Detailed Installation, Operational, and Performance Qualification (IQ/OQ/PQ) protocols and support for their execution.

Full traceability of materials and components.