Types of Air Distribution Plates in Fluid Bed Processor

As a pharmaceutical manufacturer, you must know how vital a fluid bed processor is for drying, granulating, or coating powders

Finetech provides an extensive range of fluid dryer beds that are designed to meet the requirements of modern industrial processes. All our products are durable and ensure maximum energy efficiency.

A fluid bed dryer is a piece of equipment that carefully removes moisture from materials such as powder, granules, and pellets. It helps achieve quick and uniform drying in multiple industries, from pharmaceutical to chemical. At Finetech, we have a wide range of fluid bed dryers given below:

Maximum Capacity: 5kg to 500kg

Blower Motor: 7.5 to 40 HP

Air Flow (CFM) 10%: 430 to 3825

Steam Pressure: 3.5 kg/cm2

Electric Heater: 18 and onwards kW

Drying Temperature: 35 to 80°C

Spray Granulator Capacity: Max. 300g/batch

Minimum Sample Volume: 100g

Granulator Temperature: 40-150℃

Compressed Air: 3 bar

Rated Airflow: 120 m³/h

Peristaltic Pump: Max. 1000ml/h

Body Material: SUS304 Stainless steel

| Model | Unit | FTFL-5 | FTFL-10 | FTFL-30 | FTFL-60 | FTFL-120 | FTFL-200 | FTFL-300 | FTFL-500 | |

|---|---|---|---|---|---|---|---|---|---|---|

| Raw material container | Volume | L | 22 | 38 | 100 | 220 | 420 | 670 | 1000 | 1500 |

| Diameter | mm | 400 | 450 | 700 | 1000 | 1200 | 1400 | 1600 | 1800 | |

| Rproduction capacity | Kg/time | 5 | 10 | 30 | 60 | 120 | 200 | 300 | 500 | |

| Steam | Pressure | Mpa | 0.2-0.4 | 0.2-0.4 | 0.2-0.4 | 0.2-0.4 | 0.2-0.4 | 0.2-0.4 | 0.2-0.4 | 0.2-0.4 |

| Consumption | Kg/h | 18 | 30 | 60 | 120 | 140 | 180 | 310 | 400 | |

| Compressed air | Pressure | Mpa | 0.6-0.8 | 0.6-0.8 | 0.6-0.8 | 0.6-0.8 | 0.6-0.8 | 0.6-0.8 | 0.6-0.8 | 0.6-0.8 |

| Consumption | M3/min | 0.3 | 0.6 | 0.6 | 0.9 | 0.9 | 1.1 | 1.1 | 1.5 | |

| Fan power | Kw | 3 | 4 | 5.5 | 11 | 18.5 | 22 | 30 | 45 |

Depending on the materials, a control panel allows you to set the temperature and air flow and optimize the drying process.

Adjustable Air Flow and Temperature:

Provides clean air by removing particles as small as 0.3 μm in size.

HEPA Filter:

Alarms and warnings to notify professionals when the system needs to shut off, whether due to overheating or other malfunctions. There's also an emergency stop button, which is quickly accessible, allowing you to stop the machinery's movement with one press.

Safety Mechanisms:This section provides a basic overview of the key components and applications of fluidized bed dryers, helping you gain a deeper understanding of their use in the pharmaceutical industry!

As a pharmaceutical manufacturer, you must know how vital a fluid bed processor is for drying, granulating, or coating powders

Many products, from foods to medicines, need careful drying to be safe and effective. This drying process often requires very

Whenever a pharma company considers buying a Fluidized Bed Dryer (FBD), sensors are one of the first things they ask

Have you ever wondered how medicines like tablets or capsules are made so perfectly and safely to use? Behind the

yes , we providing it!

Please check here:

When air velocity through a perforated bed plate reaches the minimum fluidization velocity, particles become suspended. They behave like a fluid—mixing vigorously, preventing agglomeration, and exposing maximum surface area to hot air. This creates uniform temperature distribution throughout the bed.

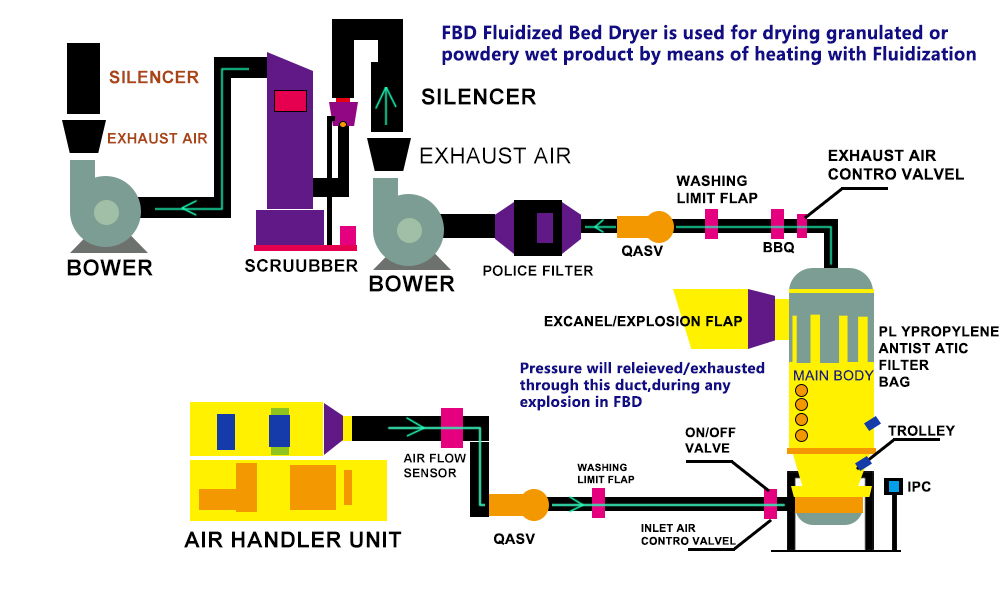

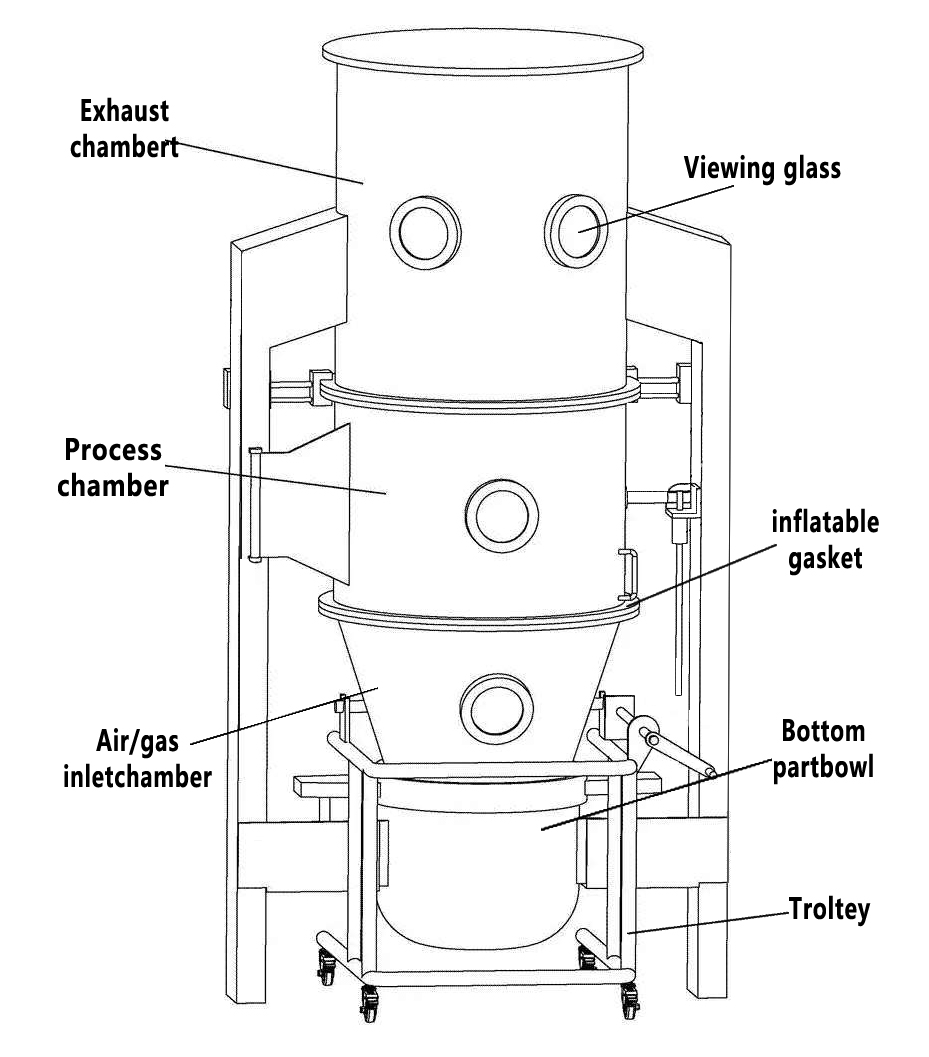

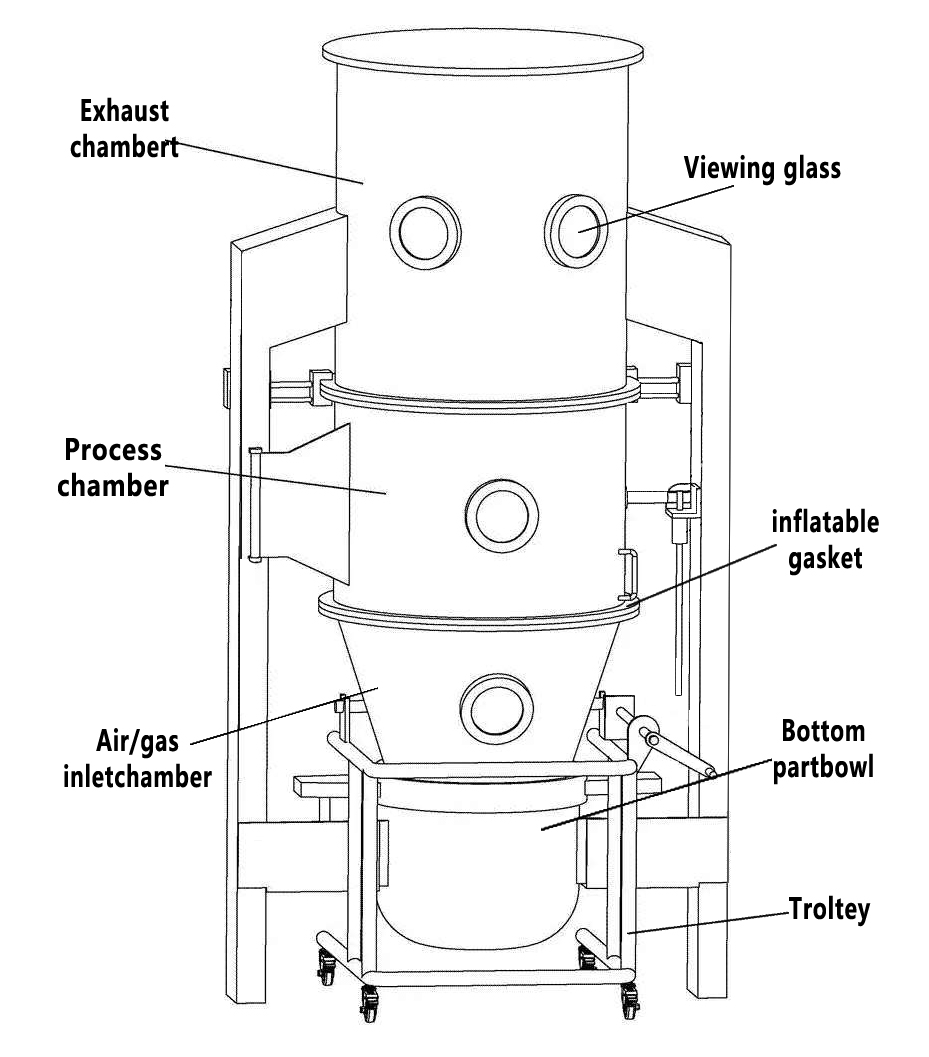

Product Container/Column: Holds the material on a distribution plate

Air Handling Unit (AHU): Filters, heats, and controls airflow

Heating System: Electric heaters, steam coils, or indirect heaters

Blower/Fan: Creates airflow through the system

Filters (Bag Filters): Retain product while allowing air/moisture to escape

Control Panel: Monitors/controls temperature, airflow, dew point

Discharge System: For dry product removal

Exhaust System: Removes moist air

FBD: Fastest drying (minutes/hours), uniform drying, good for heat-sensitive materials

Tray Dryer: Batch process, longer drying times (hours/days), potential uneven drying

Vacuum Dryer: For heat-sensitive or flammable solvents, lower temperatures, longer cycle times

Pharmaceutical granules (after wet granulation)

Powders, crystals, pellets

Food products (coffee, milk powder, cereals)

Chemicals, polymers, catalysts

Herbal extracts, nutraceuticals

Materials that are free-flowing enough to fluidize

Rapid Drying: High heat/mass transfer rates

Uniform Drying: Even temperature distribution prevents localized overheating

Controlled Parameters: Precise control of temperature, airflow, humidity

Versatility: Can be used for drying, granulating, coating (with modifications)

Efficient: Lower energy consumption per kg of water removed vs. tray dryers

GMP Compliance: Designed for pharmaceutical standards

Inlet Air Temperature: Typically 40-80°C for pharma (depends on product)

Airflow Velocity/Volume: Must exceed minimum fluidization velocity

Product Bed Temperature: Key indicator of drying progress

Dew Point/Exhaust Humidity: Indicates moisture removal rate

Drying Time

Filter Shake/Fluidization Interval: Prevents filter clogging

Loss on Drying measures the moisture content in granules. Final LOD is critical for:

Tablet compression quality

Product stability and shelf life

Preventing microbial growth

Ensuring proper dissolution

Varies by product load, moisture content, and parameters. Typically:

Small batches (5-50 kg): 15-60 minutes

Production batches (100-500 kg): 1-3 hours

Much faster than tray drying (which takes 8-24 hours)

Insufficient airflow (below minimum fluidization velocity)

Cohesive/sticky materials that form clumps

Uneven particle size distribution

Improper distribution plate (clogged holes)

Too much or too little material in the container

Product contact parts: 316L stainless steel (pharma grade)

Surface finish: Ra ≤ 0.5 µm (electropolished) for easy cleaning

Gaskets: Silicone, EPDM, PTFE (based on temperature and cleaning agents)

Filters: Polyester, polypropylene, PTFE-coated fabrics

Inlet air must be clean, dry, and controlled:

HVAC-grade filtration (pre-filters, HEPA if required)

Dehumidification for consistent drying

Temperature control for process reproducibility

For sterile products: sterile filtration of inlet air

Yes, as a Fluid Bed Granulator. Liquid binder is sprayed onto fluidized powder, forming agglomerates. The same equipment can dry them in-situ (one-pot processing).

WhatsApp us

Supply fresh, heated, and filtered air for the fluidization and drying of different materials.

Inlet Air Handling Unit