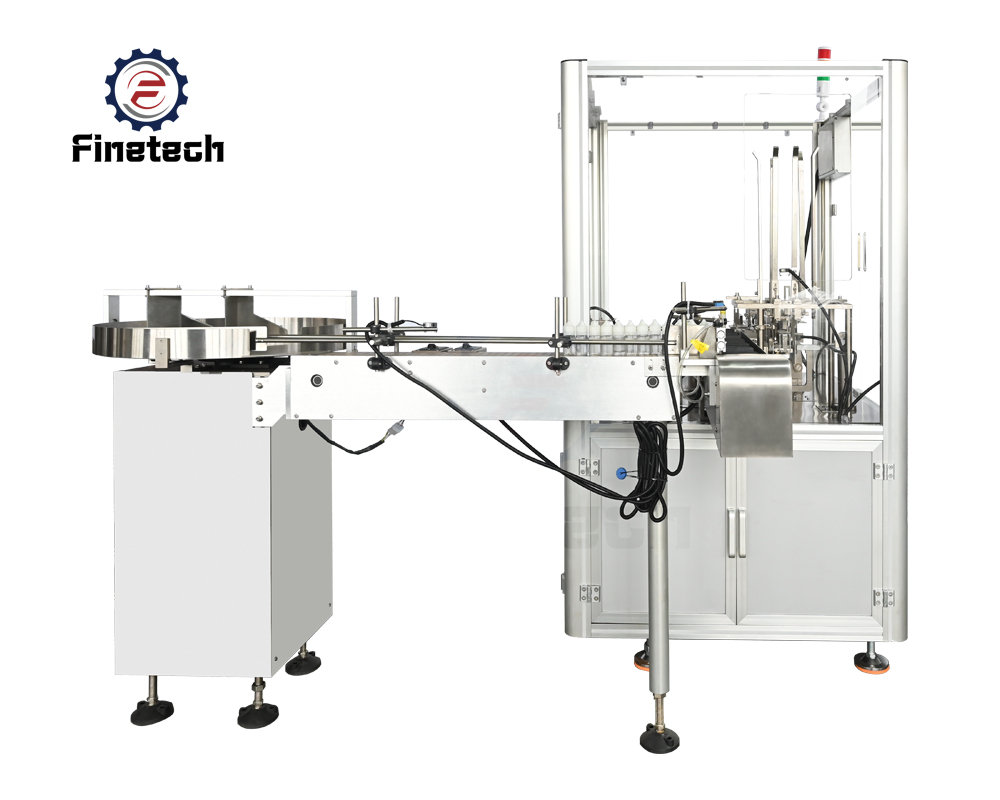

FTZH-120 Automatic Vertical Cartoning Machine

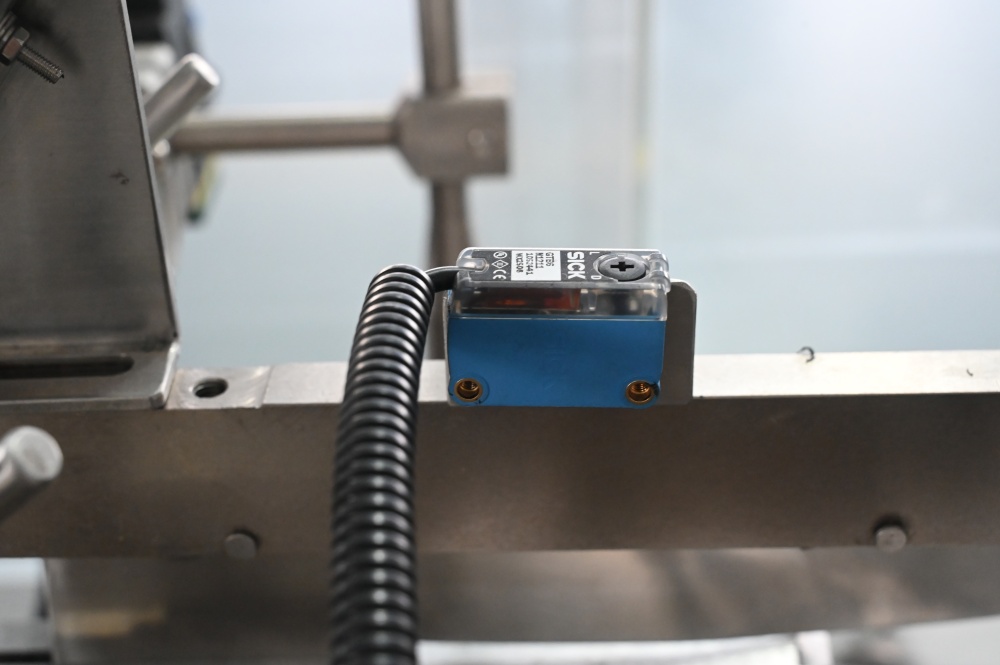

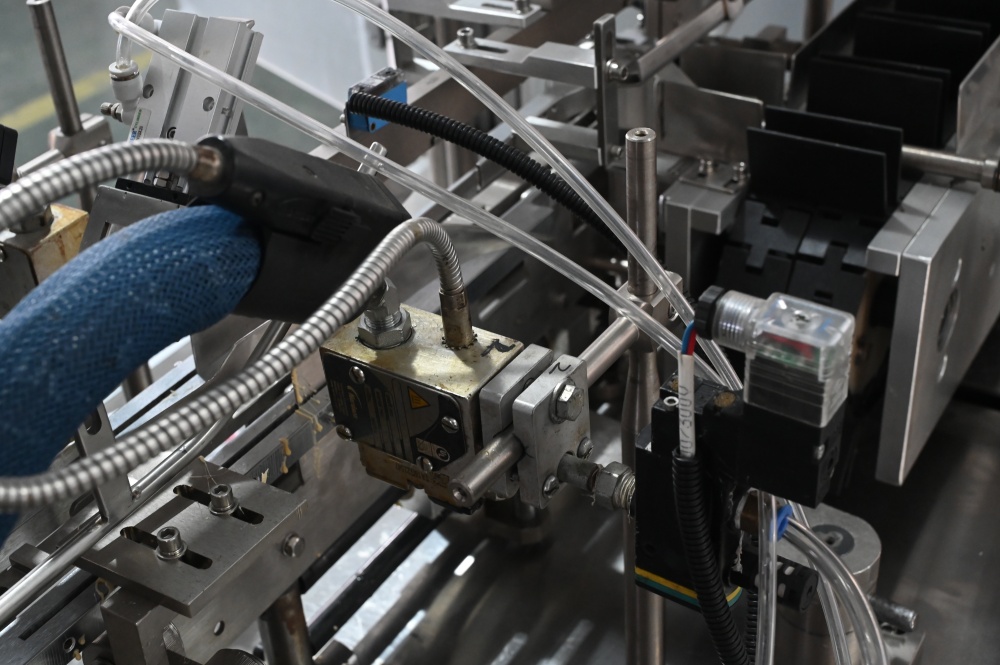

The TFZH-120 Vertical cartoning machine is a high-efficiency automated cartonning device designed for the pharmaceutical, food, cosmetics, and other industries. It uses an advanced rotary structure for continuous and stable operation. The machine includes an automatic feeding system, photoelectric sensors, and leaflet inspection to monitor product position and status in real time, ensuring accurate and reliable cartoning.

Its modular design allows quick changeovers and packing different product sizes. It also has an energy-saving standby mode to reduce power use, approved green production standards. With stable performance and smart controls, the TFZH-80 is a great choice to boost cartonning efficiency and keep product quality, helping companies move toward automated production.

Need a Custom Quote?

Or More information About this product? Contact our sales stuff today!

Key Features

Technical Data

Machine Details

FAQ

Application

1. This equipment is specifically designed for low-volume, multi-sized carton packaging.

2. Compact in footprint, cost-effective, and compatible with different carton sizes.

3. It saves labor costs and can pack up to 40 cartons per minute per operator, greatly improving production efficiency.

4. The entire machine is made of stainless steel 304.

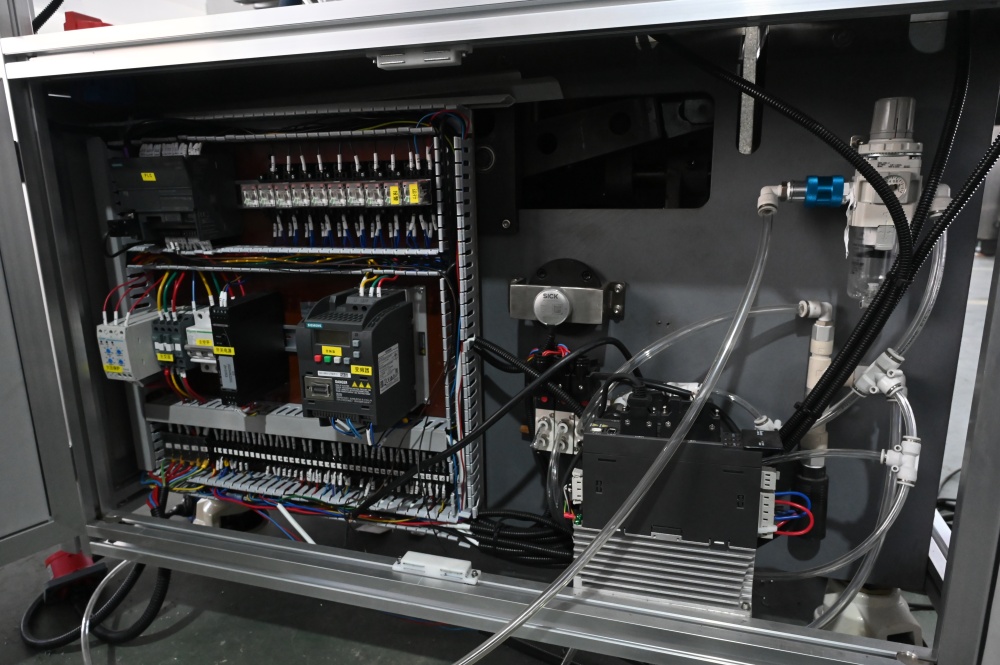

5. It features advanced PLC control with a touch screen interface. Production speed can be easily adjusted without changing any other settings.

6. The electrical control system uses an imported encoder and centralized control system, making it simple and easy to operate.

7. It is the first domestic machine with a carton feeding system that allows adding new cartons without stopping production.

8. The front end can connect with liquid fillers, blister packers, pillow packers, and other packaging machines for fully automatic packing. The rear end connects with labeling, strapping, heat shrink, and 3D packaging machines.

9. Optional features include: production date printing, automatic leaflet insertion, hot melt glue sealing, and automatic feeding devices.

| Model | FTZH-120 Vertical Atomatic Cartoning Machine |

| Packing speed | 50-80 Cartons/min |

| Carton size range | L(40-200)mm*W(12-100)mm*H(12-100)mm |

| Carton gram requirements | 135-350g/m³ |

| Motor power | 2.5KW |

| Power supply | Three phase 380V 50Hz |

| Machine noise | ≤80dB |

| Air pressure | 0.5-0.8 Mpa |

| Air consumption | 150L/min |

| Dimension | 1590*1380*1832 mm |

| Weight | 650Kg |

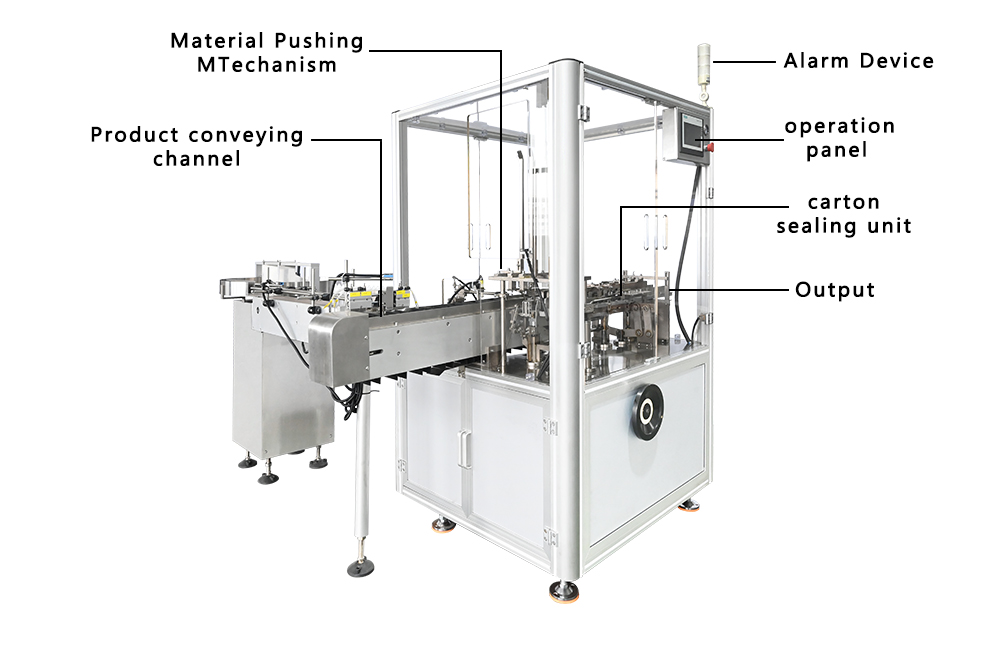

A Vertical Cartoning Machine is a type of packaging automation that erects cardboard cartons from a flat blank, loads the product vertically (from the top), and then closes and seals the carton. The key characteristic is that the product is dropped or placed down into the open carton while it is held in a vertical position.

A standard machine consists of:

Carton Magazine: Holds a stack of flat, knocked-down carton blanks.

Carton Erecting Section: Suction cups pull a single blank from the magazine and form it into a rectangular tube.

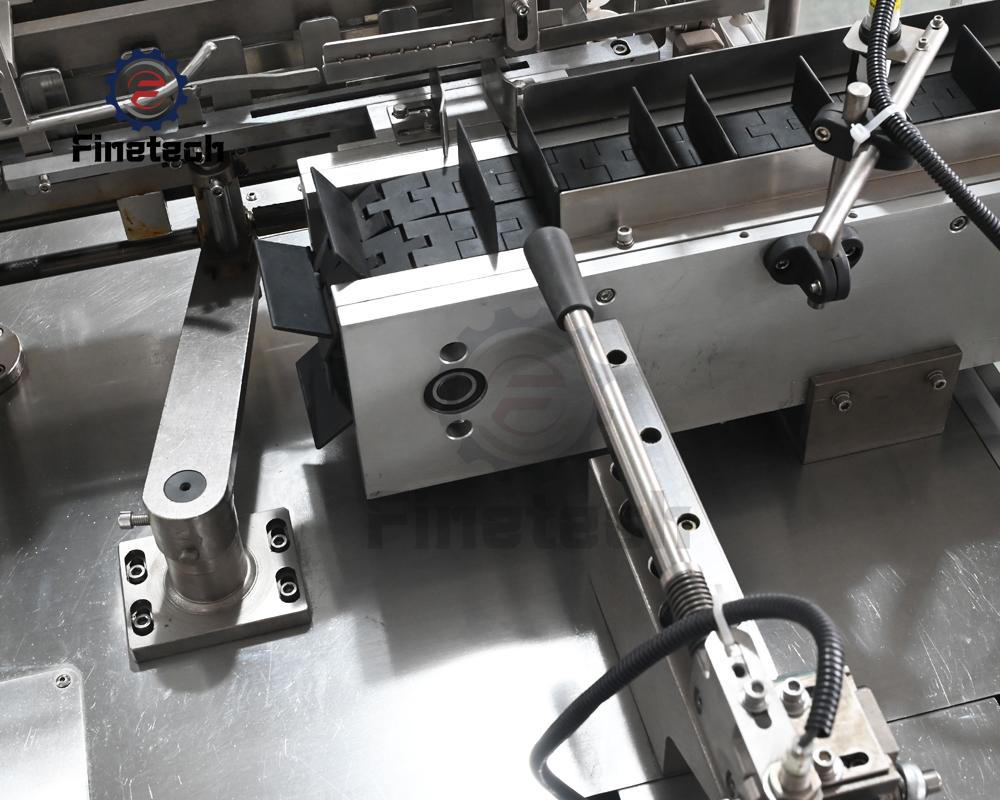

Bottom Flap Sealer: Folds and seals the bottom flaps of the carton (usually with hot melt glue).

Product Loading Zone: The heart of the machine. The product is fed and precisely dropped into the open vertical carton.

Leaflet Inserter (Optional): Automatically places an instruction leaflet or coupon on top of or inside the product.

Top Flap Closing & Sealing: Folds the top flaps and seals them with glue, tape, or tucks them.

Food & Beverage: Soup pouches, spice packets, coffee, candy bars, tea bags, bottled water, juice boxes.

Pharmaceuticals: Medicine bottles, vials, blister packs, ampoules, syringes (pre-filled).

Personal Care & Cosmetics: Bottles of shampoo/lotion, perfume boxes, soap bars, toothpaste.

Fast-Moving Consumer Goods (FMCG): Batteries, lightbulbs, small hardware items.

High Speed: Capable of very high production rates (e.g., 100+ cartons per minute).

Gravity-Assisted Loading: The simple drop-in mechanism is reliable and minimizes complexity.

Compact Design: Takes up less factory floor space compared to an equivalent horizontal machine.

Cost-Effectiveness: Generally a lower initial investment than a horizontal machine for similar speeds.

Efficiency with Pouches: Ideal for flexible packaging that can easily be conveyed and dropped.

Speeds can range from 50 to over 80 cartons per minute (CPM), depending on the machine's sophistication, product, and carton complexity.

Product Specifications: Size, weight, shape, and fragility.

Carton Specifications: Style, size range, and material.

Required Speed (CPM): Your production output needs.

Changeover Frequency: How often you will switch products/cartons.

Integration: Does it need to connect to upstream (e.g., pouch machine) and downstream (e.g., case packer) equipment?

Budget: Consider not just the initial price but also cost of spare parts, maintenance, and operational efficiency.

Vertical cartoners typically run tuck-end or glue-end style cartons. Reverse tuck is very common. The machine must be specifically set up and tooled for the carton style.