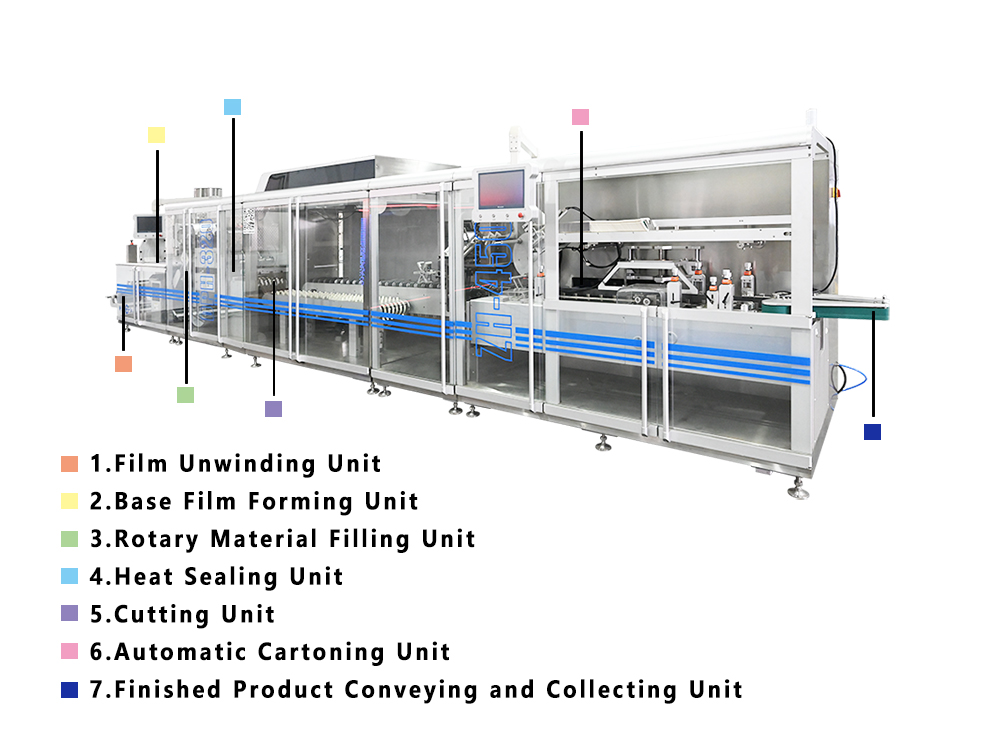

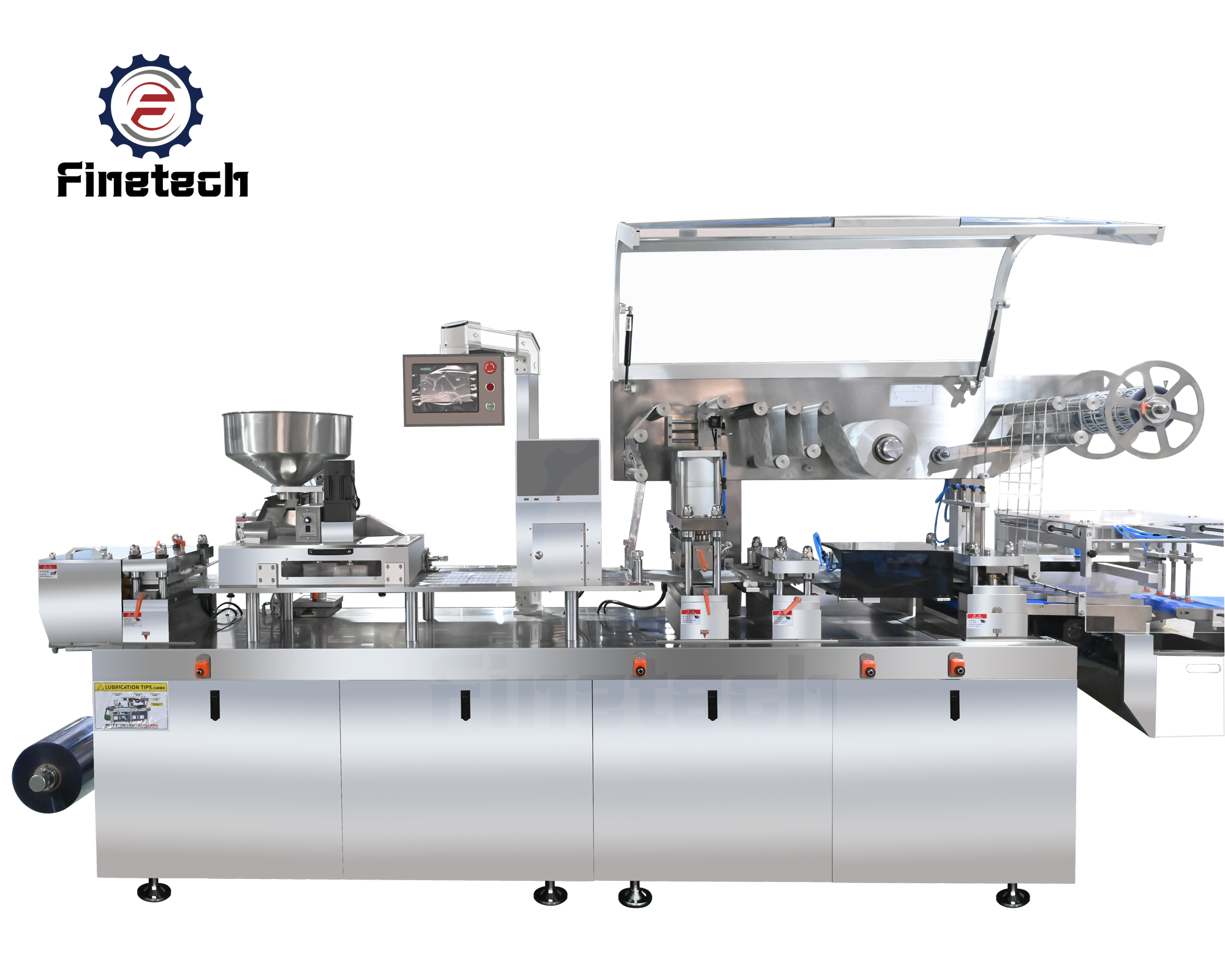

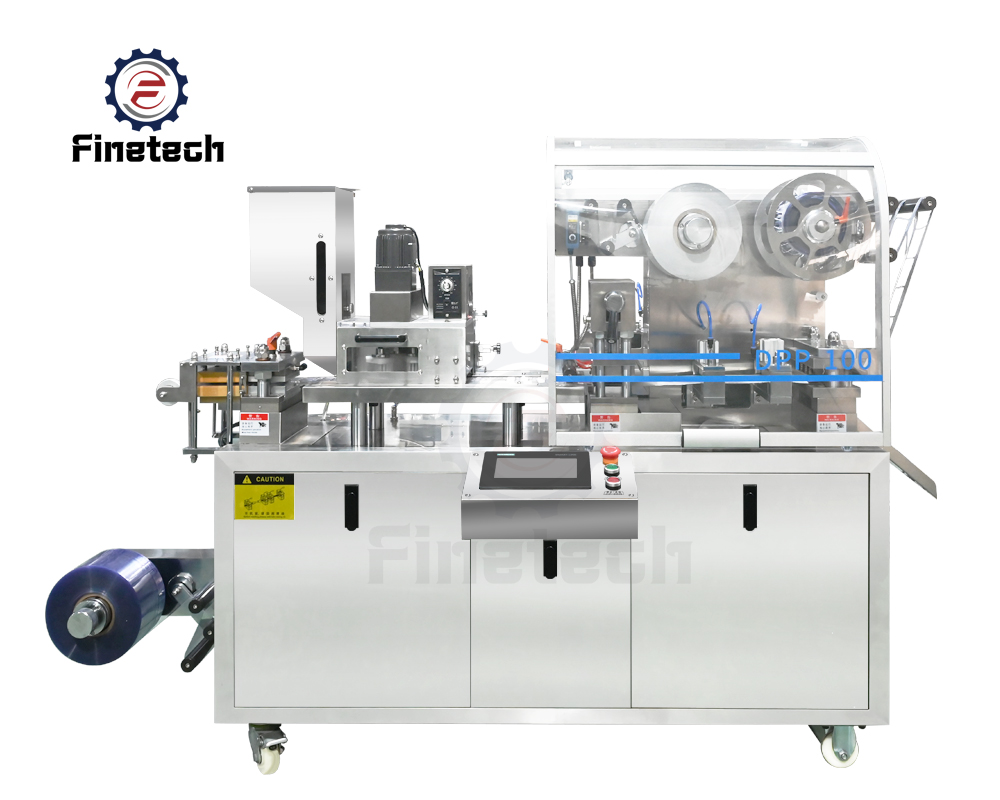

DPH-320 High Speed Roller Blister Packaging Machine

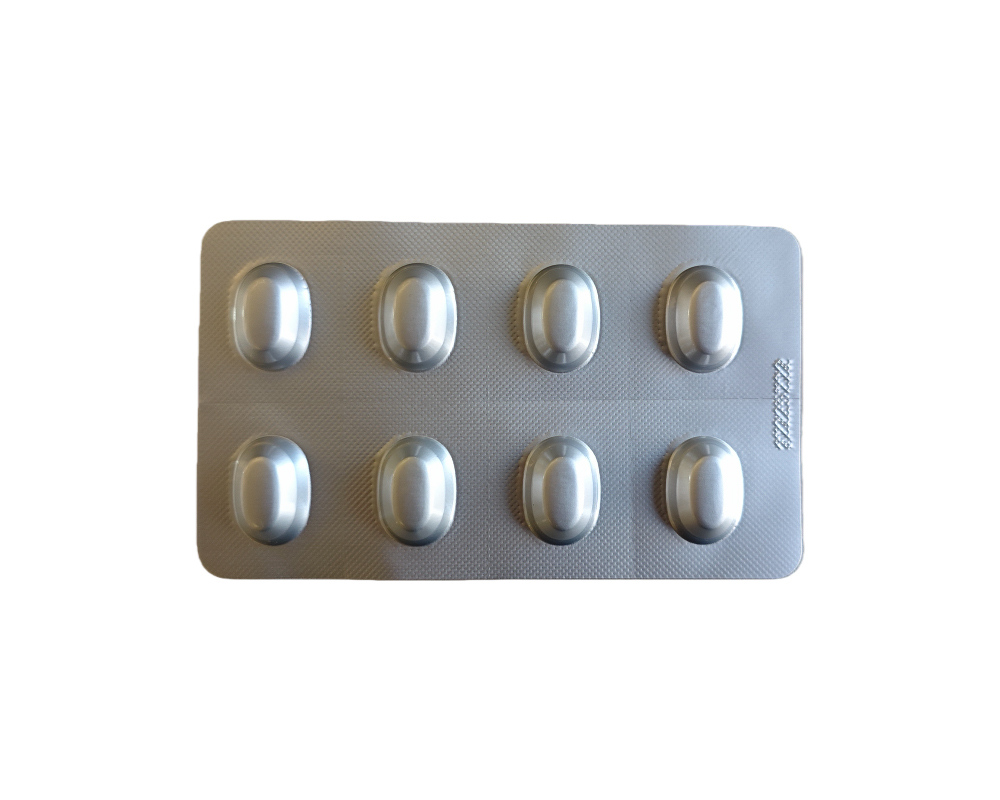

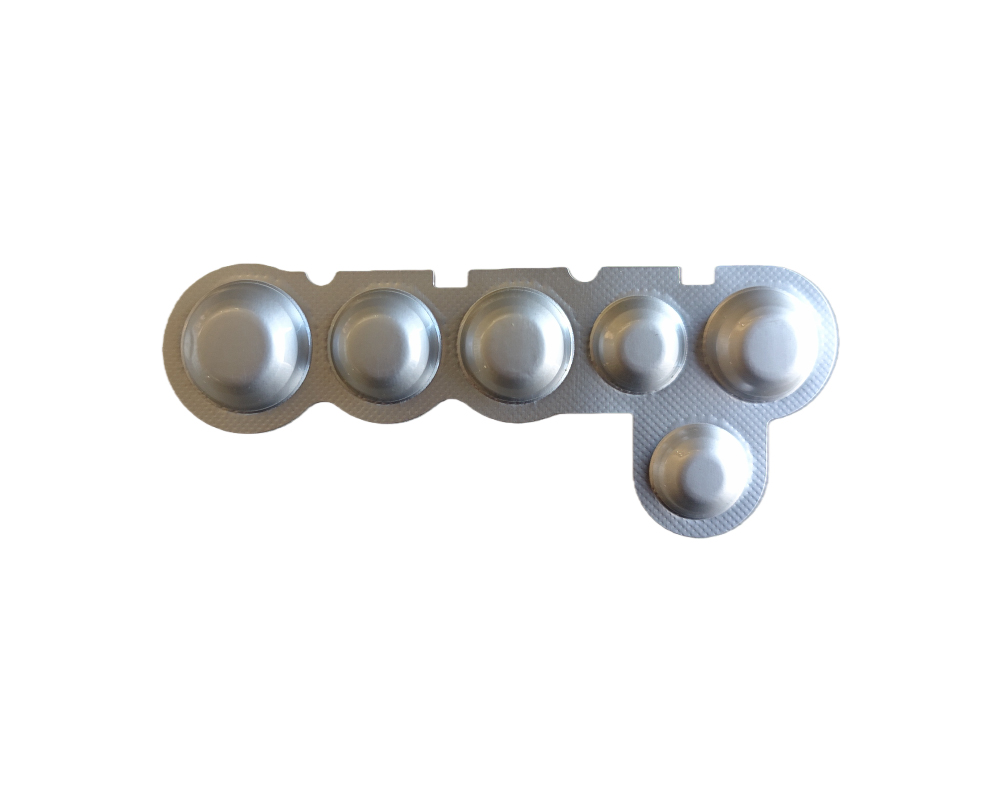

The DPH-320 is a high-performance, fully automatic rotary blister packaging machine. It uses a fast rotating drum feeding system along with precise heat sealing. It works with aluminum-plastic composite films (PVC, PVDC, aluminum foil) and is perfect for large-scale, individually sealed packaging of medicines, health supplements, food, and medical devices.

The machine features smart PLC control and a servo drive system, ensuring fast and stable operation. It is an excellent choice for modern pharmaceutical, health supplement, and food companies with large production needs.

Need a Custom Quote?

Or More information About this product? Contact our sales stuff today!

Key Features

Technical Data

Machine Details

FAQ

Application

The machine uses a high-speed rotary drum feeding system combined with precise heat sealing, allowing large volumes of products to be packaged quickly. This improves production efficiency while saving energy.

It has a smart PLC control system, making it highly automated and easy to operate. The programmable interface supports fully automated production and keeps packaging quality stable.

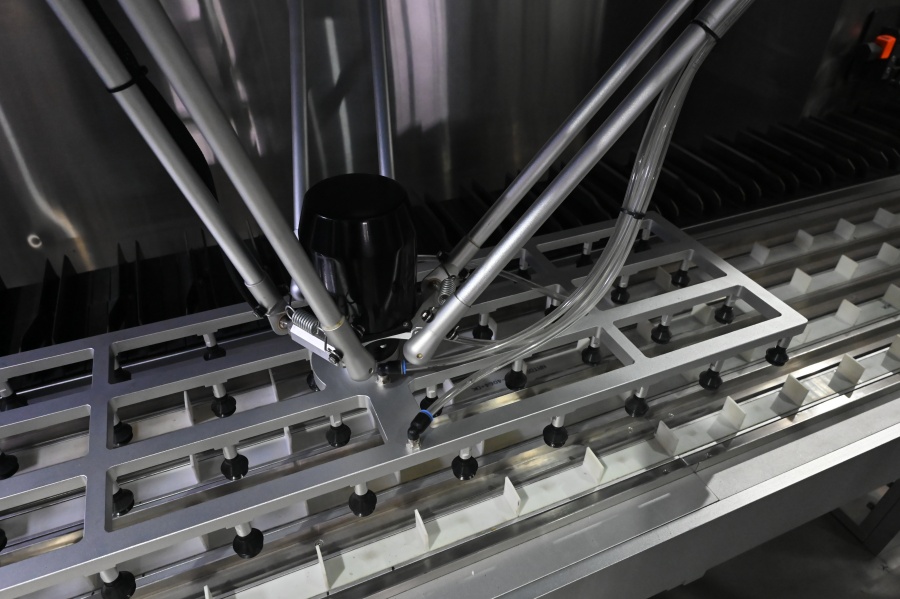

The machine accurately controls the length, width, and height of packaging material to ensure each product is properly sealed in its blister, enhancing both appearance and protection.

Designed for easy use, it includes fault alarms and automatic shutdown to quickly detect and handle problems, keeping production safe.

Made from high-quality stainless steel and meeting GMP standards, it ensures a clean and safe packaging process, suitable for pharmaceuticals, food, and related industries.

| Machine | DPH320 Alu-Pvc Blister Packing Machine |

| Max design speed(cut/min) According to blister size | 250 blister plates |

| Max material line speed | 15 |

| Max forming depth | 12 |

| Max forming depth (belt width) | 320*260 |

| Max index length | 260 |

| Max material width | 320 |

| Max cutting length | 100 |

| Power | Supply: AC380V/3-Phase/50Hz Consumption: about 20Kw |

| Air | Pressure: 0.6-0.9MPa, Consumption: <15 m3/h |

| Water | Temperature: 15-20°C, Water: about 0.2 m3/h |

| Dimension (including feeder, L*WxH) (mm) | 4750x1680x2200 |

| Weight | About 4000 Kg |

The core difference is the forming mechanism:

Platen Machine: Uses a flat mold that closes and opens in a stamping motion. This is an intermittent process.

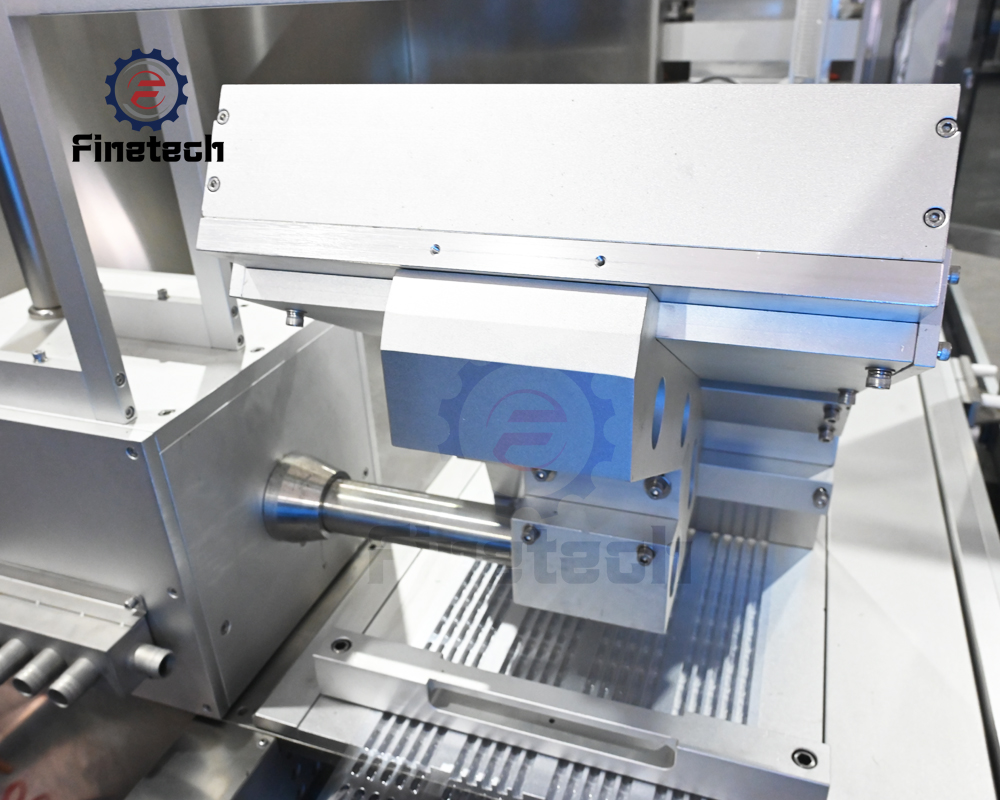

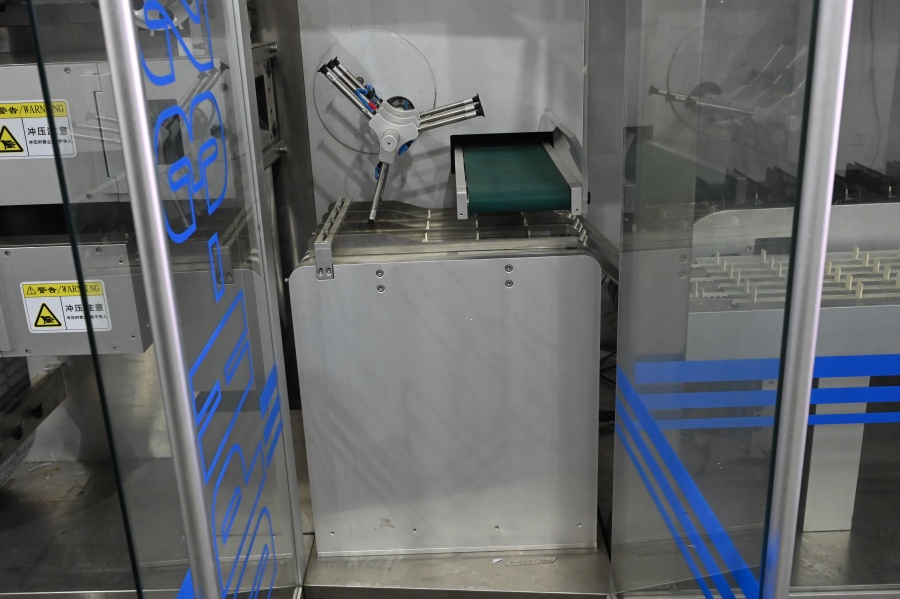

Roller Machine: Uses a rotating cylindrical mold. The film is wrapped around this mold, and pockets are formed in a continuous rolling motion. This eliminates the start-stop cycle, allowing for much higher speeds.

Roller blisters are the fastest in the industry. Speeds typically range from 300 to over 1,000 blisters per minute, depending on the product size, number of cavities, and machine model.

Due to its continuous rotary motion. There is no deceleration or stopping for the forming and sealing stages, which are the primary bottlenecks in platen machines. It's like the difference between a car driving on a open highway (roller) versus one stopping at every intersection (platen).

It is compatible with standard thermoformable films (PVC, PP, PET, Aclar) and aluminum lidding foil. However, the material must have excellent consistency and be on large-diameter rolls to support the high-speed, continuous operation.

Extremely High Output: Unmatched speed for mass production.

Higher Efficiency & OEE: Less inertia and vibration reduce wear and tear, leading to greater overall equipment effectiveness.

Gentler on Product: The continuous forming process can be gentler on fragile tablets compared to the rapid stamping of a platen.

Lower Noise Levels: The smooth rotary motion generates less noise than the repetitive clamping of a platen machine.

Primarily the high-volume pharmaceutical industry and the nutraceutical industry (e.g., vitamins, supplements) where millions of identical units are produced.

Absolutely. It is designed to be the centerpiece of a ultra-high-speed packaging line, seamlessly integrated with:

High-Speed Cartoners

Robotic Case Packers

Advanced Vision Inspection Systems (100% inspection is mandatory at these speeds).