Tablet/Capsules Strip Packaging Machine

Tablet Strip Packing Machine is an automated pharmaceutical machine designed to package tablets or capsules into blister packs (strips).

Explore Finetech's Tablet/Capsules Strip Packaging Machines

The strip packing machine forms pockets (blisters) in a base web of thermoplastic material (like PVC or PVC-free alternatives), fills the tablets or capsules into these pockets, and then seals a lidding material (typically aluminum foil) on top. The final product is a secure, tamper-evident, and patient-friendly strip.

FTB-160 features an advanced structure, high efficiency, low noise and easy operation. Its production capacity can reach 800 PCS/Hour.

Avaliable to pack the Tablets, capsules and Electronic Components in the pharmaceutical industry. Its production capacity can reach 1200 pcs/hour.

Applied for automatic aluminum-aluminum foil heat sealing packing for tablets, candy and pills. Production capacity reach to 4000 tablets/Hour.

Strip Packaging Specifications

| Model | FLB-160 | FLB-220 | FLB-300 | FLB-400 | FLB-500 | |

| Speed Of Drum: | 7 – 15 r/min rpm(stepless) | |||||

| Packing Dimensions: | 160mm | 220mm | 300mm | 400mm | 500mm | |

| Packing Material Specification: | PVC for medicine | 0.05-0.1x160mm | 0.05-0.1x220mm | 0.05-0.1x300mm | 0.05-0.1x400mm | 0.05-0.1x500mm |

| AL-plastic combined film | 0.08-0.10x160mm | 0.08-0.10x220mm | 0.08-0.10x300mm | 0.08-0.10x400mm | 0.08-0.10x500mm | |

| Hole dia of reel | 70-75mm | |||||

| Electro Thermal Power: | 1.5kw*2 | 1.8kw*2 | 2.5kw*2 | 3 kw*2 | 3.5kw*2 | |

| Main Motor Power: | 0.37kw | 0.75kw | 0.75kw | 0.75kw | 5 sets of servo drives | |

| Air Pressure: | 0.5-0.6Mpa | |||||

| Air Supply: | ≤0.1m³/min | |||||

| Overall Dimensions(LxWxH) | 1600x850x2000mm | 1600x850x2000mm | 1600x850x2000mm | 1800x1120x2000mm | 1860x1170x2300mm | |

| Weight: | 800kg | 900kg | 950kg | 1200kg | 1400kg | |

Strip Packaging Applications

Our strip tablet packaging machine is commonly used for solid dosage form products such as capsules, pills, and candies.

More Details About Tablet Strip Packaging Machine

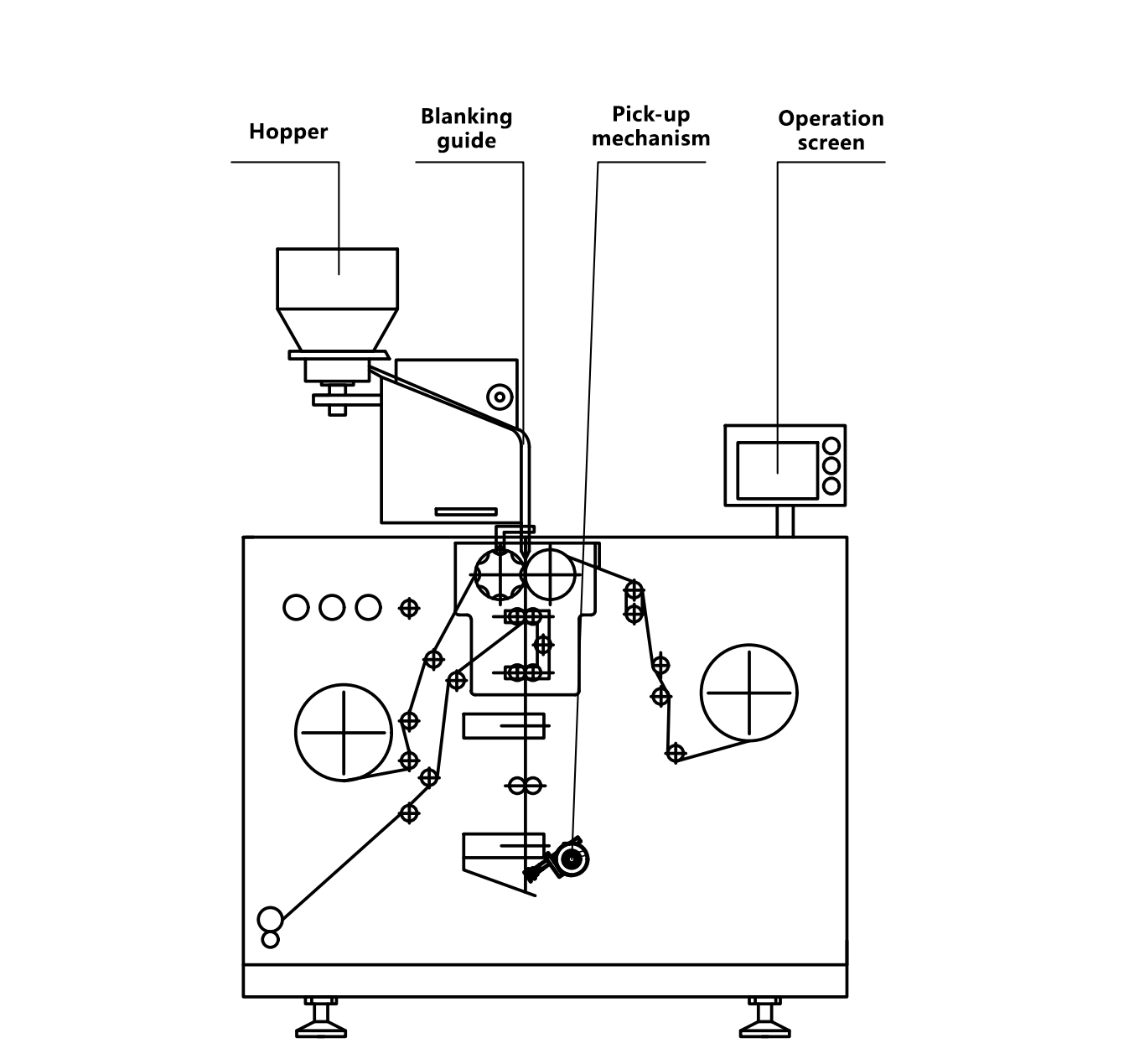

Key Parts of Tablet Strip Packaging Machine

The operator's control panel. It allows for starting/stopping the machine, setting parameters (speed, temperature), monitoring performance, and diagnosing faults.

Human-Machine Interface (HMI) Touchscreen

The container that holds the bulk supply of tablets/capsules. It often has a conical shape and may include agitators or vibratory pads to prevent bridging and ensure a consistent flow.

Product Hopper

The holder for the large roll of forming film (usually PVC or Aclar). It often includes a brake system to maintain tension on the web.

Unwind Unit / Reel Stand

A camera-based system that checks for broken, misshapen, or incorrect tablets, and verifies print quality on the lidding foil.

Vision Inspection System

A set of matched tools that perforate and cut the continuous sealed web into individual strips or blisters of the desired size and configuration.

Punch & Die (Cutting Station)How do Tablet Strip Packaging Machine Work

Tablet strip packaging machine commonly used in solid dosage forms. Please check the working principle below.

- Step 1, Make the Pockets (Forming): A roll of plastic film is heated and pushed into a mold to create the blister pockets.

- Step 2, Fill the Pockets (Filling): Tablets from a hopper are dropped, one by one, into each pocket.

- Step 3, Put the Lid On (Sealing): A thin layer of foil is placed over the top. Heat and pressure are applied to seal the foil onto the plastic, trapping the tablets inside.

- Step 4, Print the Info (Printing): Important details like the expiry date and batch number are printed onto the foil.

- Step 5 Cut into Strips (Punching): The large sheet of sealed blisters is cut into small, individual strips that you see at the pharmacy.

Tablet/Capsules Strip Packaging Machine Q&A

Its primary purpose is to package individual tablets or capsules into unit-dose blister packs (strips). This protects the product from moisture, light, and contamination, provides tamper evidence, and improves patient compliance.

Base Film (Forming Film): Typically PVC (Polyvinyl Chloride). For better moisture protection, PVC/PVDC or Aclar is used.

Lidding Foil: Usually aluminum foil with a heat-seal coating on one side. It can be printed or plain.

It follows a simple “Form, Fill, Seal” process:

Form: Heats a plastic film and forms pockets (blisters) using a mold.

Fill: Drops one tablet or capsule into each pocket.

Seal: Applies a foil lid and heat-seals it shut. The continuous sheet is then cut into individual strips.

Yes, but it requires a changeover. You need to change the forming die (to create the right pocket shape) and the feeding system (to handle the new product gently and accurately). Modern machines are designed for quick changeovers.

Yes, but you must select the correct high-barrier film like Aclar or cold-form aluminum blistering, which offers superior moisture protection compared to standard PVC.

Speeds vary widely by machine size and type:

Small Machines: 80 – 150 strips per minute.

Medium to Large Machines: 200 – 400+ strips per minute.

Speed depends on the number of tablets per strip and the product characteristics.

Product Range: Types and sizes of tablets/capsules you will package.

Required Output: Strips per minute/hour.

Budget: Includes machine cost, installation, and spare parts.

Regulatory Needs: Must comply with FDA, CE, or other local regulations.

After-Sales Service: Availability of technical support and spare parts.

Please check here:

Guides the finished strips out of the machine and into a collection bin or onto a conveyor for secondary packaging.

Discharge Conveyor /Collection Chute