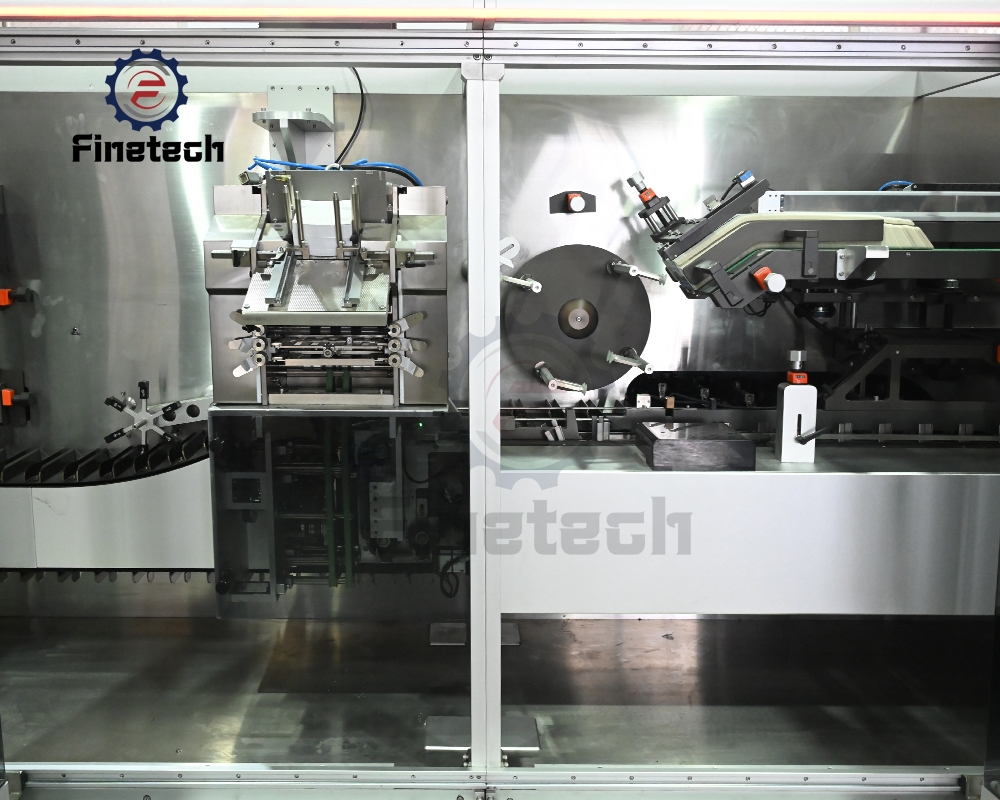

Blister Packaging Production Line

Finetech’s blister line integrates thermoforming blister packaging machines, cartoning machines, and some secondary packaging machines to achieve high-speed packaging, averaging 120,000 blister packs per hour. Widely used in pharmaceutical, cosmetic, and chemical factories.

Need a Cutsom Quote

Or More information About this product? Contact our sales stuff today!

Key Features

Technical Data

Machine Details

FAQ

Application

Our blister packaging line is designed for capsules and tablets, and can complete the packaging of capsules, blister packs, vials and ampoules in one unit.

Speed options: Choose from a capacity of 5,000, 20,000, 50,000, 70,000, 90,000, or 120,000 packages per hour.

The equipment meets GMP standards and CE certification.

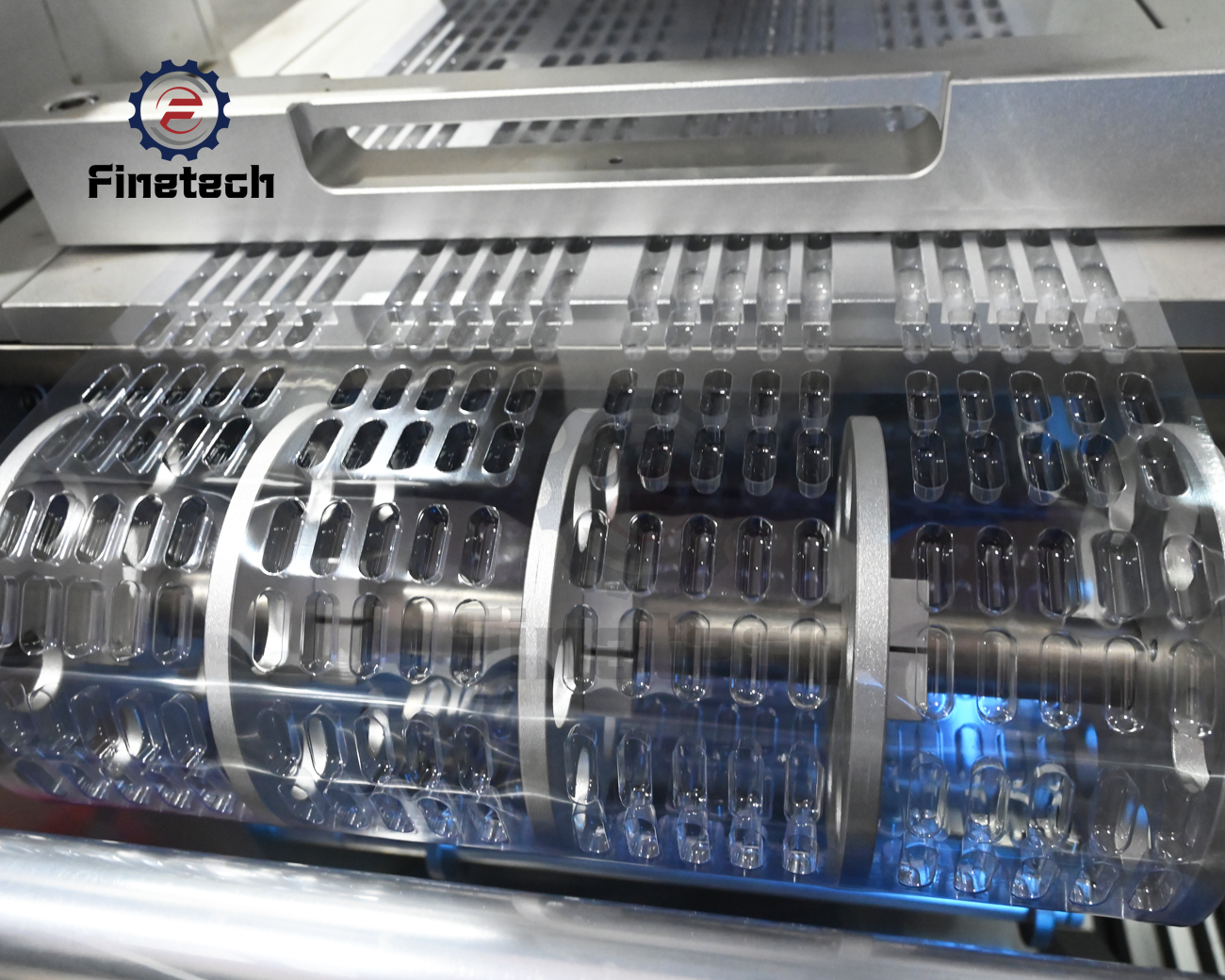

Customized production: Blister molds can be customized according to your capsule and tablet sizes.

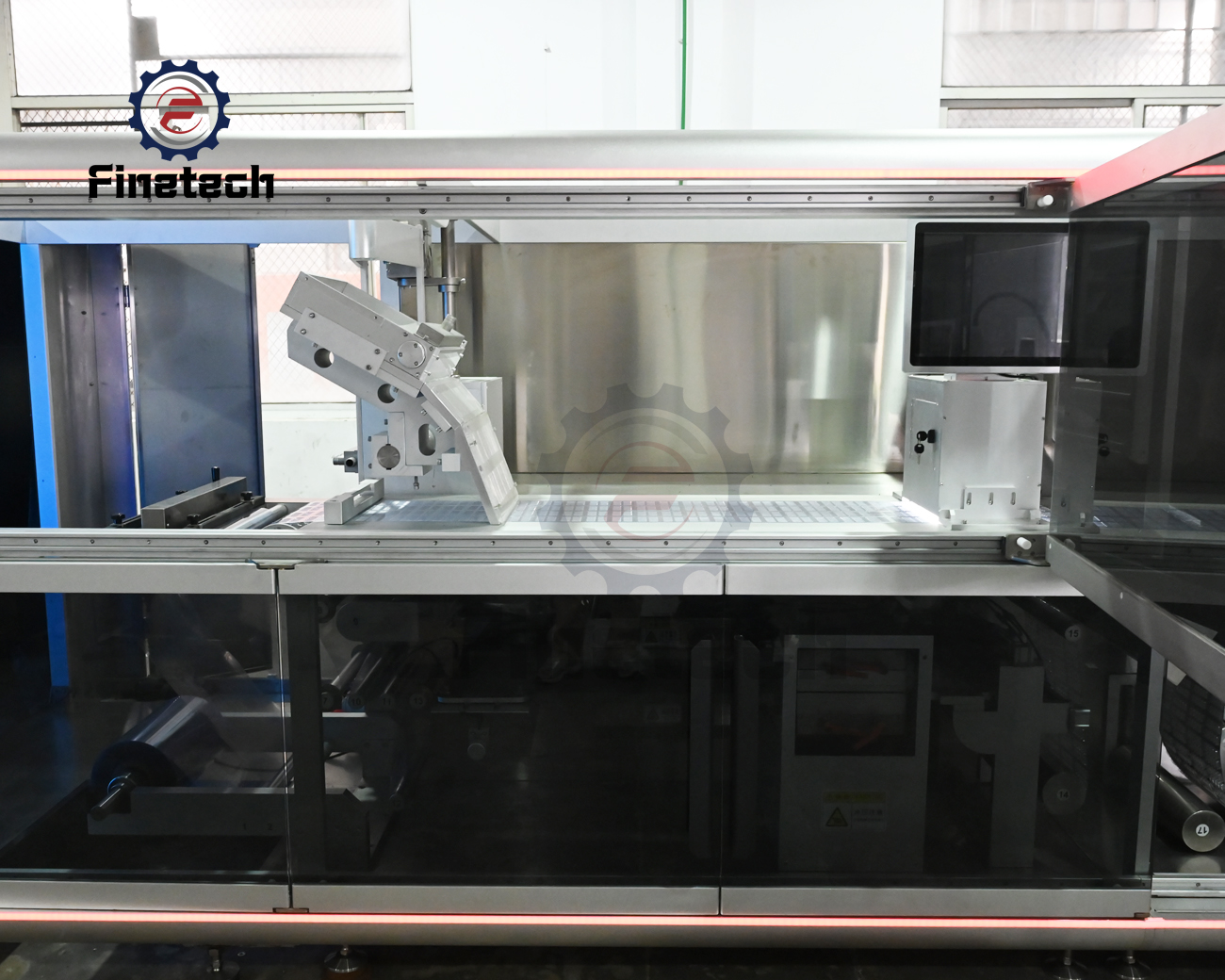

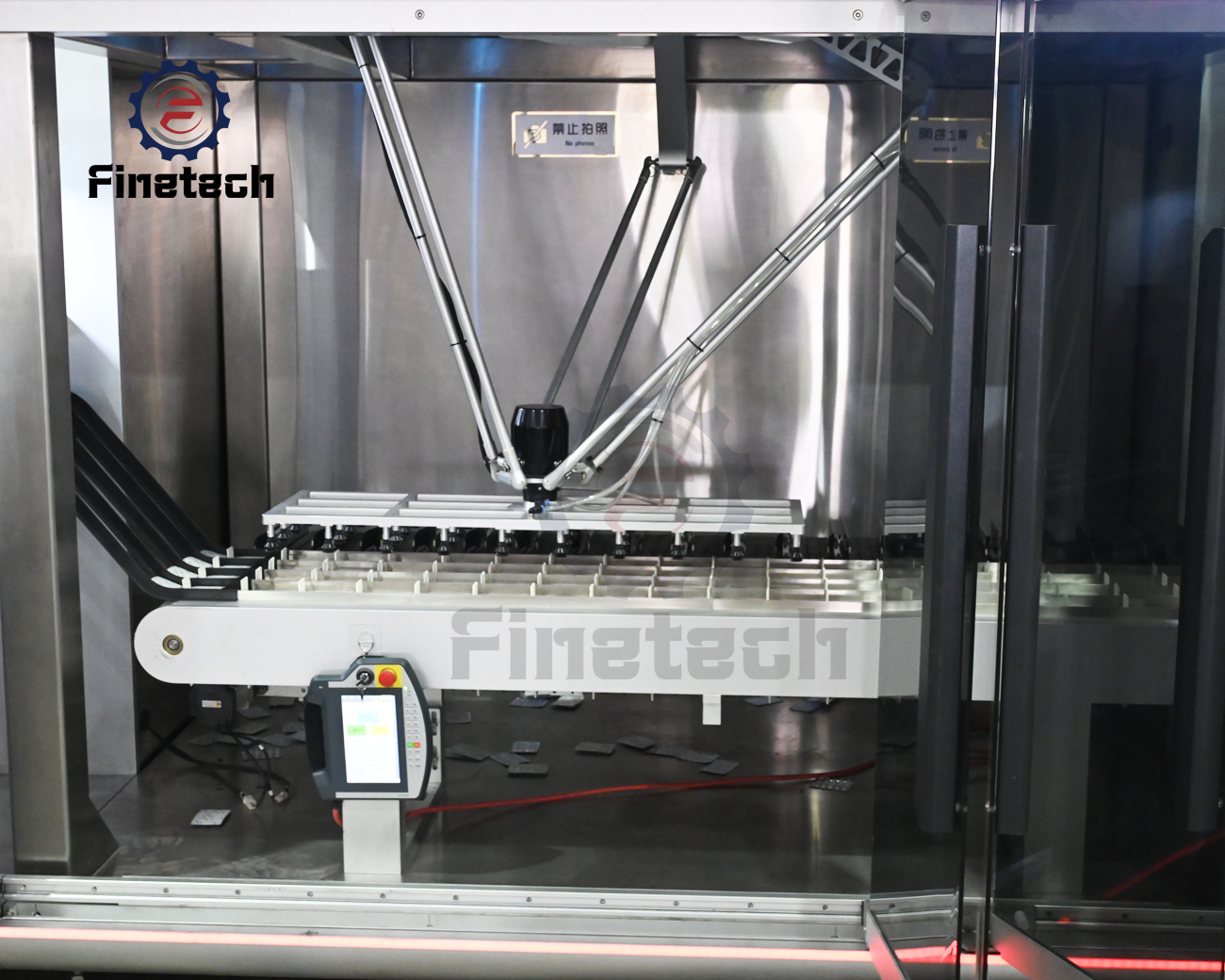

The precision servo motor control provides stable and accurate operation.

Production is controlled via an HMI to reduce format conversion time.

The blister line features a fully enclosed structure and safety doors, meeting strict safety standards.

| Model | FT-600G | |

| Flat Plate Blister Packaging Machine | punching frequency | 10-20times/min |

| max.forming area | 380x600mm | |

| adiustable scope oftravel | 50-370 mm | |

| specification of blister | candesignastherequirementofcustomer | |

| packing material | Non-toxic PVC rigid sheet (compliant with GB5663) (0.150.5) x 600mm, with reel hole diameter of 7476mm. Maximum outer diameter of rolled film: 500-600mm. | |

| electric heating power | PVC Preheating Plate 2 x 3 kW | |

| mould cooling | Tap water or circulating water at 60 L/h | |

| main motor power | 3KW | |

| packaging demensions | 8500x1650x1900mm | |

| weight | 11000kg | |

| High-Speed Cartoning Machine | cartonerspeed | 300 boxes per minute |

| specification ofcarboard case | Maximum size: 150x80x50mm Minimum size: 80x35x15mm | |

| (leaflet of medicine) | (100-250)mm × (100-170)mm (length × width) Minimum folded width: 15mm | |

| power main motor power | 245 x 112 mm, 380V 50Hz three-phase four-wire, 4KW | |

| pressure air-consumption | z0.6Mpa 0.06~0.09mmin(pressure0.6~0.9Mpa) | |

| Noise | 20.25m’/min<80DB | |

| packaging demensions | (L*W*H)3700x1700x1900mm | |

| weight | 3500kg | |

| Air pump | air-consumption | >0.2m/min |

| pressure | 0.5-1.0 mpa | |

| totalpowerofmachine | 10KW | |

| max.totalair-consumption | 260 L/min | |

| Complete machine | packagingdemensions | (L*W*H)16120x2200x1900mm |

| weight | 16500 kg | |

Forming Station: Heats and molds plastic film into blisters.

Product Feeding System: Loads tablets, capsules, or other items.

Sealing Station: Seals blister cavities with lidding material (foil/cardboard).

Punching Station: Cuts individual blisters.

Control Panel/HMI: For machine operation and monitoring.

Replace the forming mold and adjust the heat/air pressure settings. Consult the machine manual for calibration.

Misaligned film feed.

Film tension too high/low.

Foreign objects obstructing the conveyor.

Daily: Clean forming/sealing stations, check sensors.

Weekly: Lubricate moving parts, inspect molds.

Annually: Full calibration by a technician.

Blister Film: PVC, PVDC, Aclar, or COC.

Lidding: Aluminum foil, paper, or peelable films.

Optimize heat settings to reduce cycle time.

Use high-quality films to minimize jams.

Automate product feeding (e.g., robotic loaders).

Many newer machines support data logging, predictive maintenance, and OEE tracking.