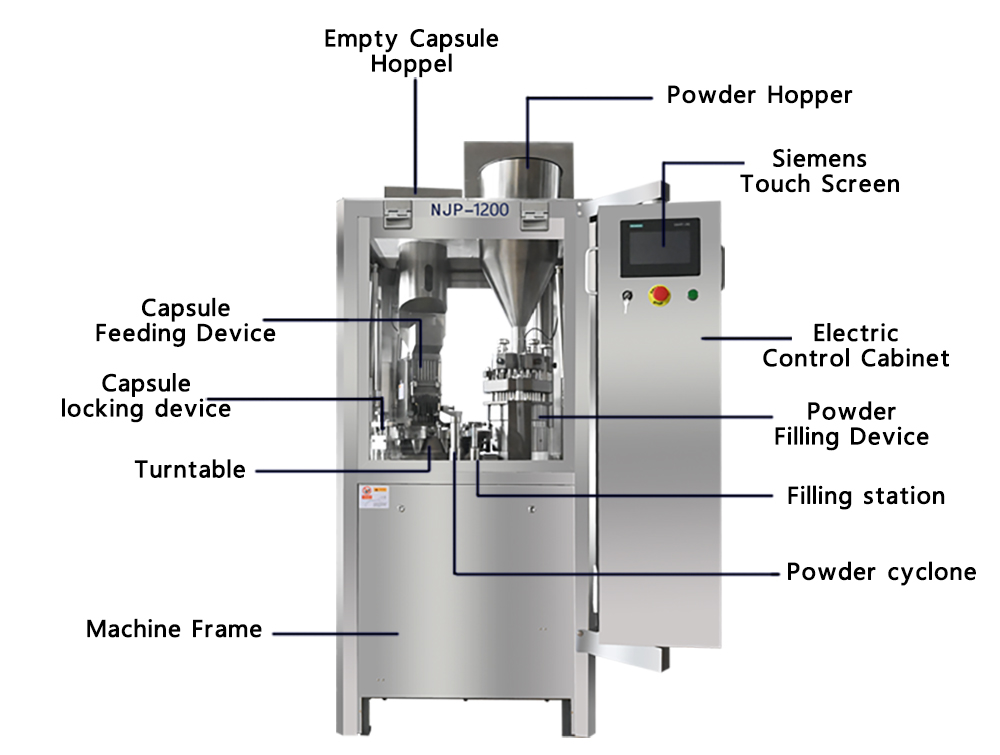

NJP-1200 Automatic Capsule Filling Machine

The NJP-1200 is a fully automatic, high-precision capsule filling machine with a dual servo drive and AI-based visual inspection. It achieves a filling accuracy of ±0.3% and supports continuous production and quick mold changes. Designed for pharmaceutical, biotech, and high-end health supplement industries, it can automatically fill complex materials like pellets, nanoparticles, and liquid soft capsules.

Need a Custom Quote?

Or More information About this product? Contact our sales stuff today!

Key Features

Technical Data

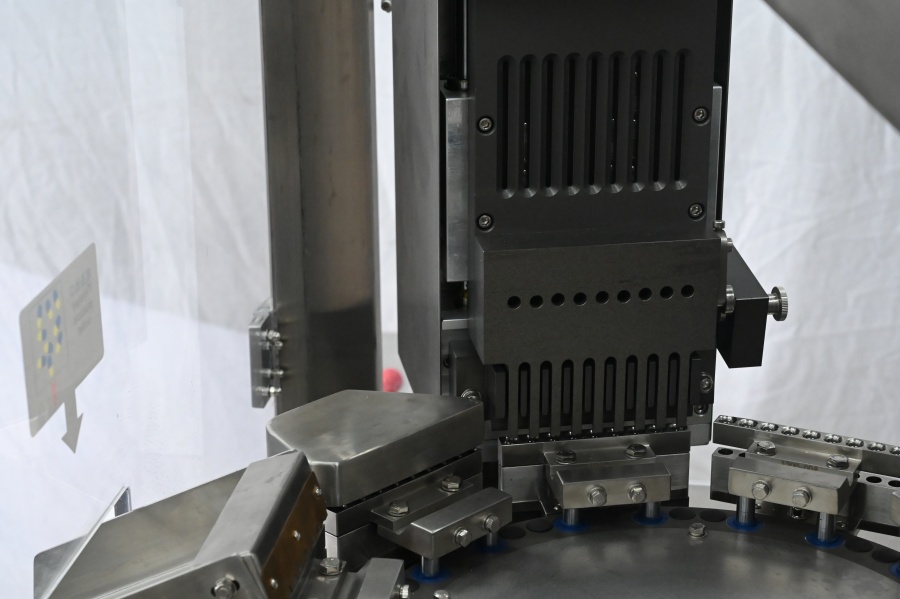

Machine Details

FAQ

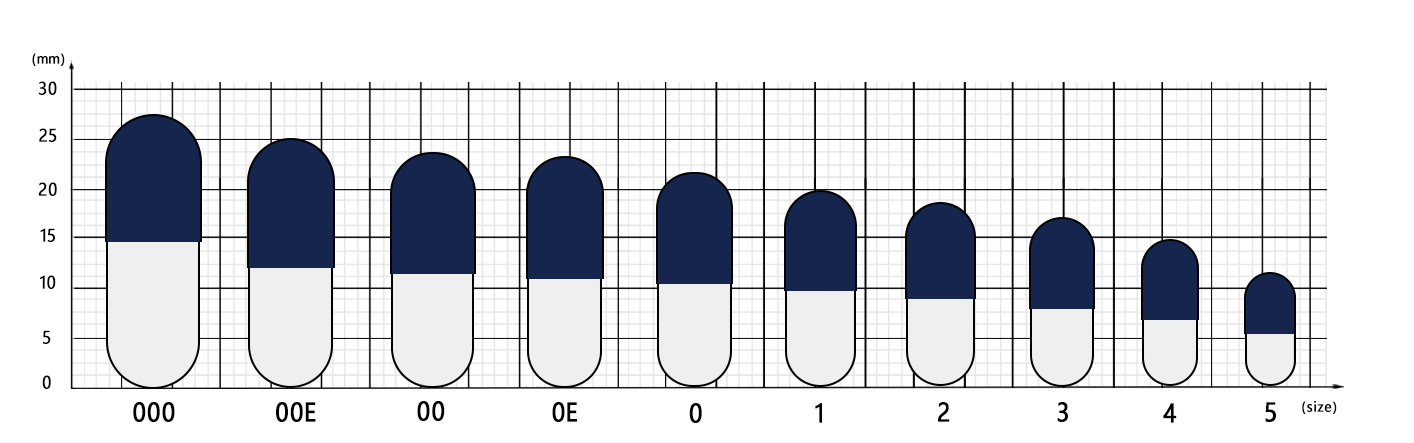

Application Capsule Size

Application Capsule Types

1. The equipment is compact, energy-efficient, easy to operate and clean, with simple mold replacement. It has a standardized, modular design with interchangeable parts for quick and accurate mold change.

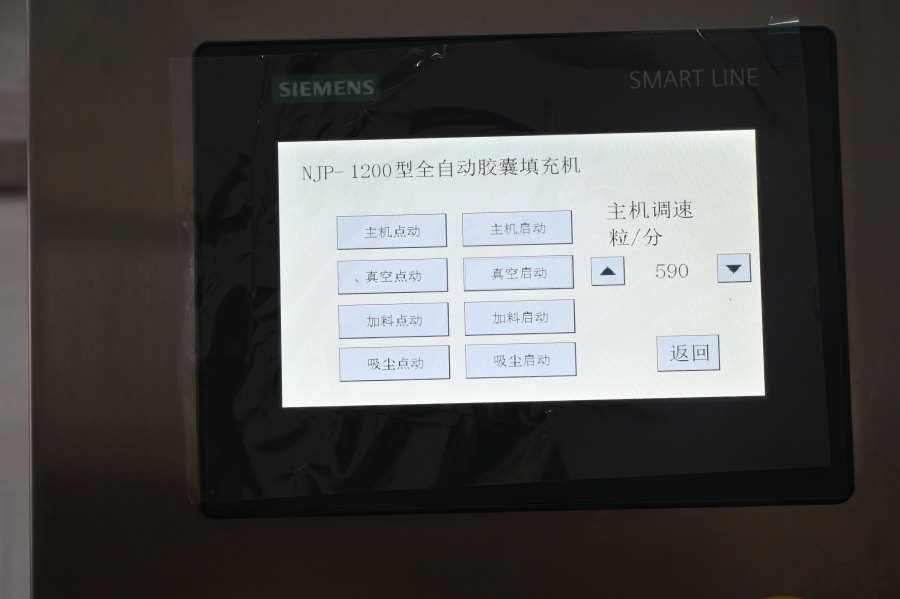

2. It uses a high-precision indexer, operates with low vibration, and has noise levels under 70 dB. The filling variation is kept within ±3%, and the capsule feeding rate is over 99.5%. Key electrical and pneumatic parts come from trusted brands like Siemens (Germany) and Omron (Japan), ensuring reliable control.

3. The platform is made of 45# flat steel with a hard chrome plating that prevents rust and deformation, improving durability. Parts in contact with powder are made of 304 or 316 stainless steel, fully meeting GMP requirements.

4. An optional powder recovery system can recover 85%–90% of lost material, helping pharmaceutical producers save costs.

| Model | NJP-1200 |

| Productivity | 72,000 capsules/h |

| Motor power | 5.75Kw |

| Power supply | Standard : 3P 380V 50Hz , Can be Customized |

| Capsule size | 00#~5# and safety capsule A~E |

| Capsule using rate | ≥ 99.5% |

| Machine weight | 900 Kg |

| Overall dimension | 1020*860*1970mm |

| Noise index | ≤ 75 DBA |

| Dosage difference | ≤ ±3% (under more than 300mg dosing and 40~80 mesh after granulation) |

| Compressed air | air consumption 0.06m3/min pressure 0.3Mpa |

| Water supply | Water cycle pump compound water tank, or connect to a water source |

| Vacuum degree | -0.02-0.06 MPa |

| Water supply | 500L/H 0.2-0.10 Mpa |

| Enter pipe inner diameter | 20mm |

| Waterspout inner diameter | 27mm |

| Working temperature | 21℃ ± 3℃ |

| Working relative humidity | 40-55% |

| Dust Collector | 160m3/h |

| Special function | Granule and powder mixed filing; Powder collector |

| Control system | Stepless frequency conversion control, PLC touch screen |

| Material | Parts that contact medicine use superior 304 stainless steel and GMP-compliant materials |

| Compliance | Fully complies with GMP requirements |

The NJP-1200 has a theoretical maximum output of up to 72,000 capsules per hour. The actual output depends on the operator's speed, the powder characteristics, and the capsule size.

The NJP-1200 can handle standard hard gelatin or HPMC (vegetarian) capsules from size 000 (largest) to size 5 (smallest). Changing the capsule size requires a changeover of the dosing disc, capsule hopper, and the powder funnel.

Yes. The NJP-1200 is designed with Good Manufacturing Practices (GMP) in mind. All parts that contact the product (dosing disc, powder funnel, tamping pins) are easily removable without tools for cleaning and sanitization.

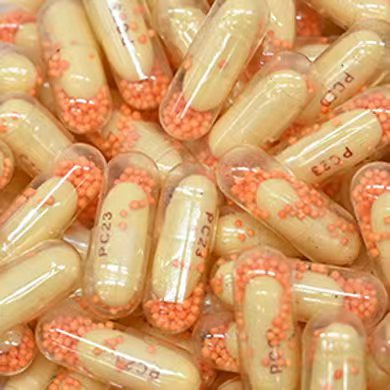

It works best with free-flowing, finely milled powders. It can handle a wide range of formulations, including:

Pure API + Excipient blends

Herbal powders

Granules (if they are uniform and not too coarse)

It struggles with extremely cohesive, sticky, fluffy, or highly oily powders without special techniques or tooling adjustments.

The standard NJP-1200 is designed for powders. Filling pellets or micro-tablets is possible but often requires a specialized dosing disc or a different filling principle (like a dosator) to ensure accurate and consistent fill weight.

Consistency relies on several factors:

Powder Properties: Ensure your powder blend is uniform, well-lubricated, and has good flowability.

Dosing Disc Selection: Use the correct dosing disc thickness for your target fill weight and capsule size.

Tamping Pressure: Adjust the tamping pins to apply consistent, gentle pressure. Over-tamping can compress the powder too much, leading to weight variation and capping.

Powder Bed Height: Maintain a consistent and adequate powder level in the powder tray.

The NJP-1200 typically operates on a standard single-phase power supply (e.g., 110V/220V, 50/60Hz), making it suitable for most labs and small production facilities. The vacuum pump may have its own power requirements.

Easy Disassembly: All product contact parts can be removed for cleaning.

Stainless Steel Contact Parts: Made from 304 or 316 stainless steel, which is non-reactive and easy to clean.

Smooth Surfaces: Minimal dead spaces where powder can accumulate.

Documentation: Reputable suppliers provide a Machine Manual, Diagram of Parts, and a Certificate of Conformity.