NJP3200/3800 Automatic Capsule Filling Machine

The NJP3200/3800 Series is a fully automatic capsule filling machine designed for high precision and medium-to-high production capacity. It offers high accuracy, low energy use, and smart maintenance features. This machine is suitable for the pharmaceutical, biotechnology, and high-end nutrition industries, and supports filling powders, granules, pellets, and liquids.

Need a Custom Quote?

Or More information About this product? Contact our sales stuff today!

Key Features

Technical Data

This is a fully automatic hard capsule-filling machine with intermittent operation and a perforated disk design. The filling and rotating parts are fully enclosed, making it easy to clean.

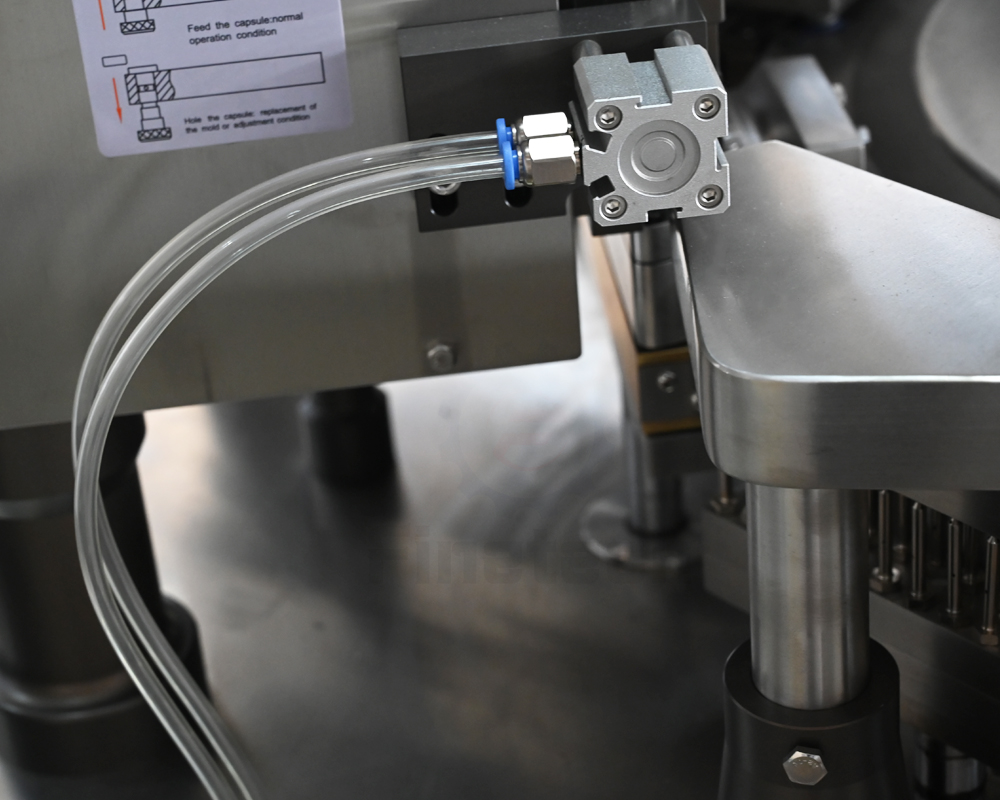

The upper and lower modules move in a single direction and utilize double-lip polyurethane seals for reliable sealing.

The cleaning station combines air blowing and suction to keep the mold holes dust-free during high-speed operation.

The capsule locking station has a powder removal system to maintain cleanliness.

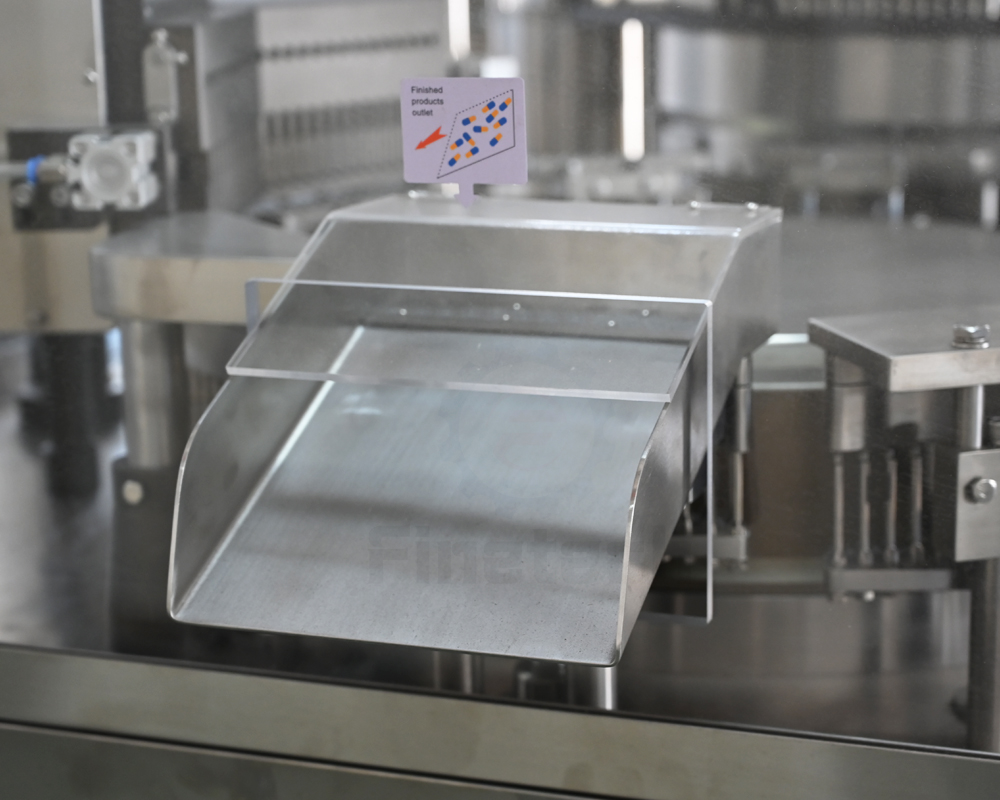

The finished capsule discharge station features a capsule-holding ring to prevent dust from spreading.

| Model | NJP-3200 |

| Productivity | 192,000 capsules/h |

| Motor power | 9.55Kw |

| Power supply | Standard : 3P 380V 50Hz , Can be Customized |

| Capsule size | 00#~5# and safety capsule A~E |

| Capsule using rate | ≥ 99.5% |

| Machine weight | 2400 Kg |

| Overall dimension | 1130*1280*2060mm |

| Noise index | ≤ 75dBA |

| Dosage difference | ≤ ±3% (under more than 300mg dosing and 40~80 mesh after granulation) |

| Compressed air | air consumption 0.06m3/min pressure 0.3Mpa |

| Water supply | Water cycle pump compound water tank, or meet water source |

| Vacuum degree | -0.02~-0.06 MPa |

| Water supply | 500L/H 0.2-0.10 Mpa |

| Enter pipe inner-diameter | 20mm |

| Waterspout inner-diameter | 27mm |

| Working temperature | 21℃ ± 3℃ |

| Working relative humidity | 40-55% |

| Dust Collector | 300m3/h |

| Special function | Granule and powder mixed filing; Powder collector |

| Control system | Stepless frequency conversion control ,PLc touch screen |

| Material | All parts in contact with medicine use superior 304 stainless steel and GMP-compliant materials |

| Compliance | Meets all GMP requirements |