NJP-400 Automatic Capsule Filling Machine

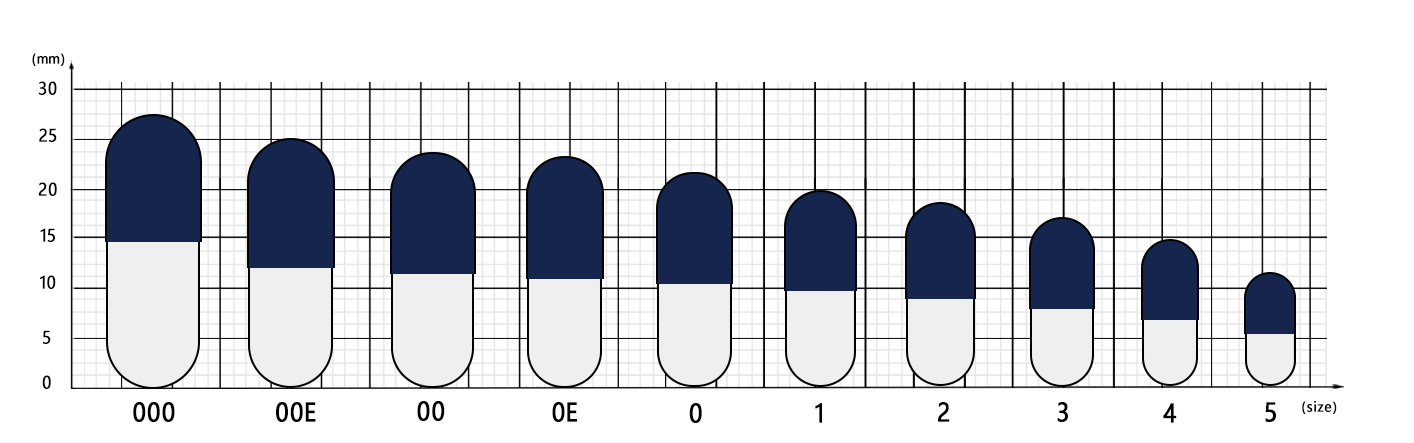

NJP-400 is designed for pharmaceutical companies, health supplement makers, and laboratories. It offers high accuracy, high efficiency, easy operation, and a modular design. It is suitable for automatically filling powders and granules used in capsules, nutritional supplements, and functional foods. The machine works with standard capsules sized 00# to 4# and meets GMP production standards. It is ideal for flexible production in small to medium batches.

Need a Custom Quote?

Or More information About this product? Contact our sales stuff today!

Key Features

Technical Data

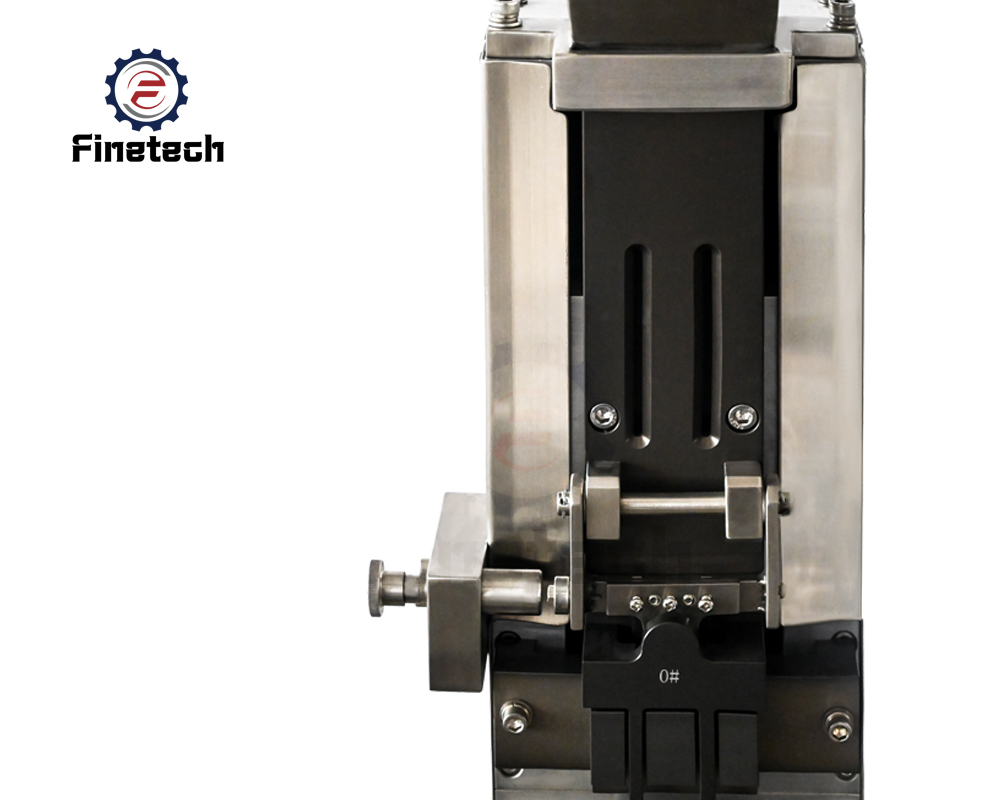

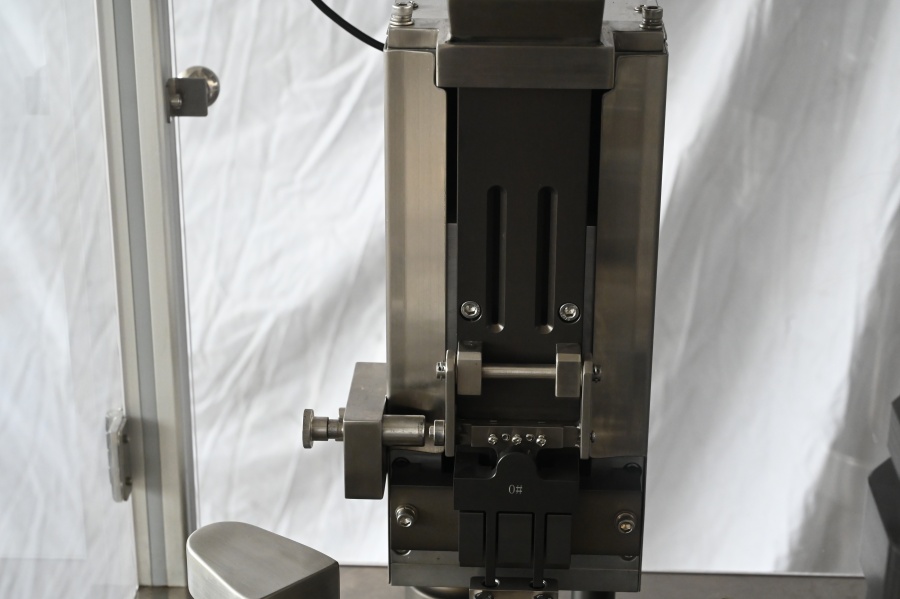

Machine Details

FAQ

Application Capsule Size

Application Capsule Types

1. The machine is compact, uses little energy, and is easy to operate and clean.

2. Standardized parts allow for easy and accurate mold changes.

3. It has a bottom-mounted cam with a pressurized oil pump that keeps the cam groove lubricated, reducing wear and extending parts’ life.

4. A high-precision indexer reduces vibration and keeps noise under 80 dB. The vacuum system ensures over 99.9% capsule feeding success.

5. The filling amount can be adjusted in three directions based on the dosing disk’s lower surface, ensuring even filling and easy cleaning.

6. The control panel is user-friendly and has many features. It automatically sounds an alarm and stops production if there is a shortage of material or capsules or if there is a blockage. It also shows the dose for each capsule and total production in real time.

| Model | NJP-400 |

| Productivity | 24000 Capsutes/H |

| Motor power | 3.7KW |

| Power supply | Standard : 3P 380V 50Hz , Can be Customized |

| Capsule size | 00#~5# and safety capsule A~E |

| Capsule using rate | ≥ 99.5% |

| Machine weight | 700 Kg |

| Overall dimension | 720*680*1700 mm |

| Noise index | ≤ 75dBA |

| Dosage difference | ≤ ±3% (under more than 300mg dosing and 40~80 mesh after granulation) |

| Compressed air | air consumption 0.06m3/min pressure 0.3Mpa |

| Water supply | Water cycle pump compound water tank, or meet water source |

| Vacuum degree | -0.02~-0.06 MPa |

| Water supply | 500L/H 0.2-0.10 Mpa |

| Enter pipe inner-diameter | 20mm |

| Waterspout inner-diameter | 27mm |

| Working temperature | 21℃ ± 3℃ |

| Working relative humidity | 40-55% |

| Dust Collector | 160m3/h |

| Special function | Granule and powder mixed filing; Powder collector |

| Control system | Stepless frequency conversion control ,PLc touch screen |

| Material | Spare part contact with medicine adopt superior S.S 304 & GMP compliable material |

| Criterion | Comply to GMP completely |

The NJP-400 is a high-speed machine. Its theoretical output is up to 400 capsules per minute, though the actual speed can vary based on the powder characteristics and operator skill.

The NJP-400 can be easily adjusted to fill all standard capsule sizes: Size 00, 0, 1, 2, 3, 4, and 5. You need to change the corresponding parts in the dosing disc, the rectifying ring, and the cap and body bushings.

It is designed for free-flowing powders. It can also handle:

Granules

Semi-flowing powders (may require a paddle feeder attachment for consistent filling)

It is not suitable for non-flowing, sticky, or highly oily formulations without significant modification and expert tuning.

Yes. The NJP-400 is built with GMP (Good Manufacturing Practice) requirements in mind. Key features include:

Contact parts made of SS 304 or SS 316 stainless steel.

Easy-to-clean design with minimal dead spaces.

A fully enclosed safety guard with interlocks (the machine stops if the guard is opened during operation).

It typically runs on a standard 220V/380V, 50/60Hz power supply. Always check the manufacturer's specifications for your specific model and region.

For a skilled operator, a complete changeover (e.g., from size 0 to size 2) typically takes 20-30 minutes. This includes changing the bushings, dosing disc, and rectifying ring, and recalibrating the fill weight.

Fill weight is adjusted primarily in two ways:

Dosing Disc Thickness: You physically change the dosing disc to one with a different thickness (e.g., 4mm, 6mm, 8mm). A thicker disc gives a heavier fill.

Powder Bed Height: The machine has a knob to adjust the height of the powder in the feeding hopper, which indirectly affects the fill weight and consistency.

Tamper Settings: Some models have tamping pins that can be adjusted to compress the powder for higher weight and density.

It is prudent to keep:

Gaskets and Seals: Wear-and-tear items that need frequent replacement.

Dosing Discs: A full set for the capsule sizes you use.

Bushings (Cap & Body): At least one set for each capsule size you use.

Rectifying Rings: One for each capsule size.

Drive Belts: Standard V-belts that can wear out.